Mesh weaving structure of hexagonal wire mesh weaving machine

A weaving machine and wire mesh technology, which is applied in braided fabrics, wire meshes, textiles, and papermaking, can solve the problems of short length of spring-shaped mesh, increased labor intensity, and complex structure, so as to achieve reasonable space layout and reduce labor intensity , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

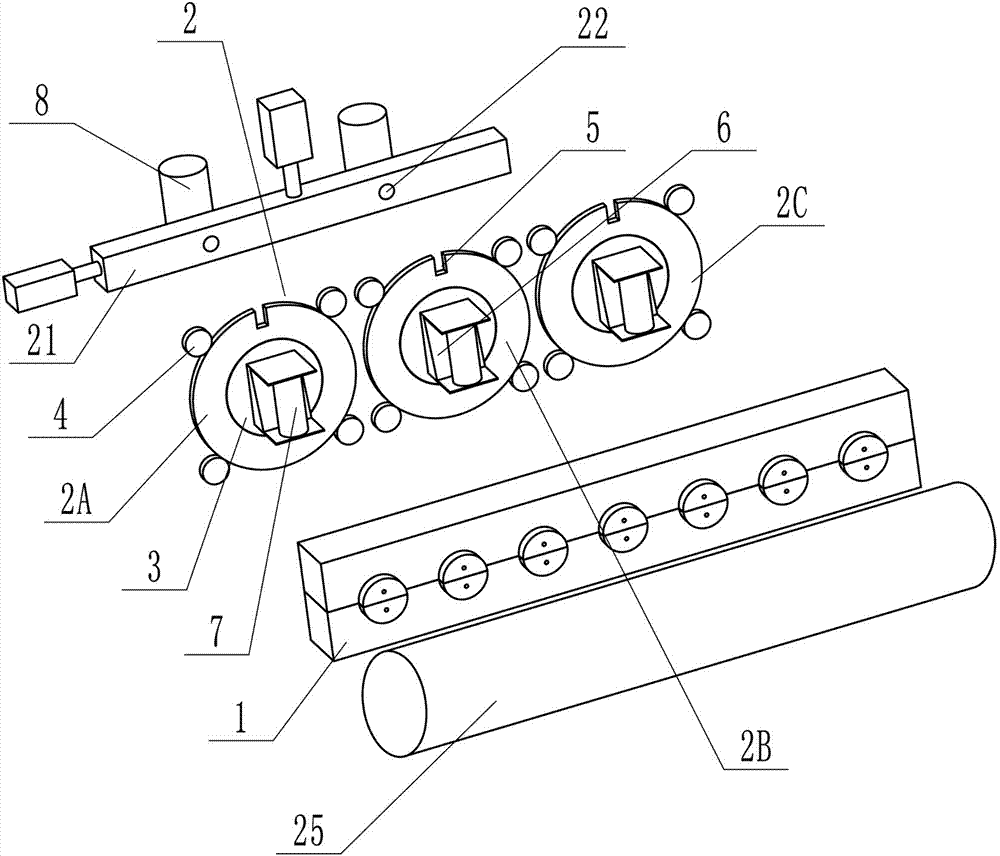

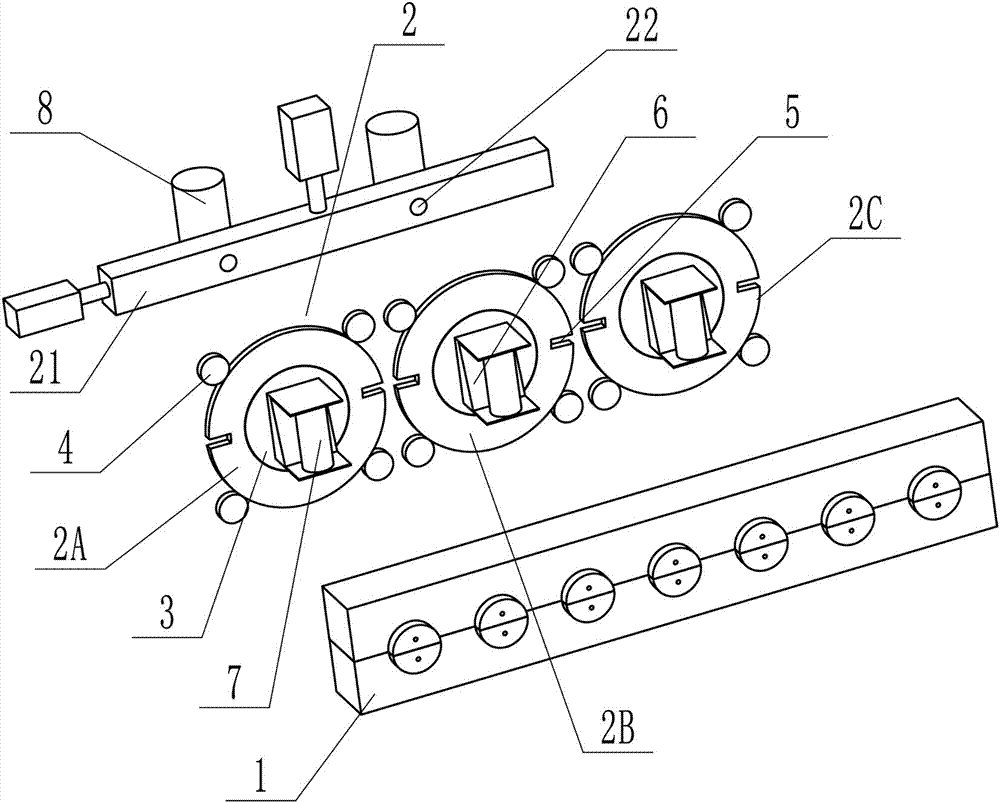

[0022] Embodiment 1: as attached figure 1 , 2 , 5, the present invention includes a wire twisting device 1 for twisting the mesh into the required shape of a hexagonal screen, a first wire feeding device 8 arranged behind the twisting device for feeding wire to the twisting device, The rotating device used to rotate the mesh wire is arranged between the first wire feeding device 8 and the wire twisting device. The rotating device includes more than two gear plates 2. Between the rotating device and the first wire feeding device 8 Between is provided with the wire pulling device that is used to dial the mesh wire from a gear plate 2 to the gear plate 2 adjacent to it and the second wire feeding device 7 that is used to feed the wire to the twisting device.

[0023] When the thread twisting device performs the thread twisting work, the mesh wire on the first wire feeding device 8 is rotated synchronously by the rotating device, which can effectively prevent the mesh silk behind...

Embodiment 2

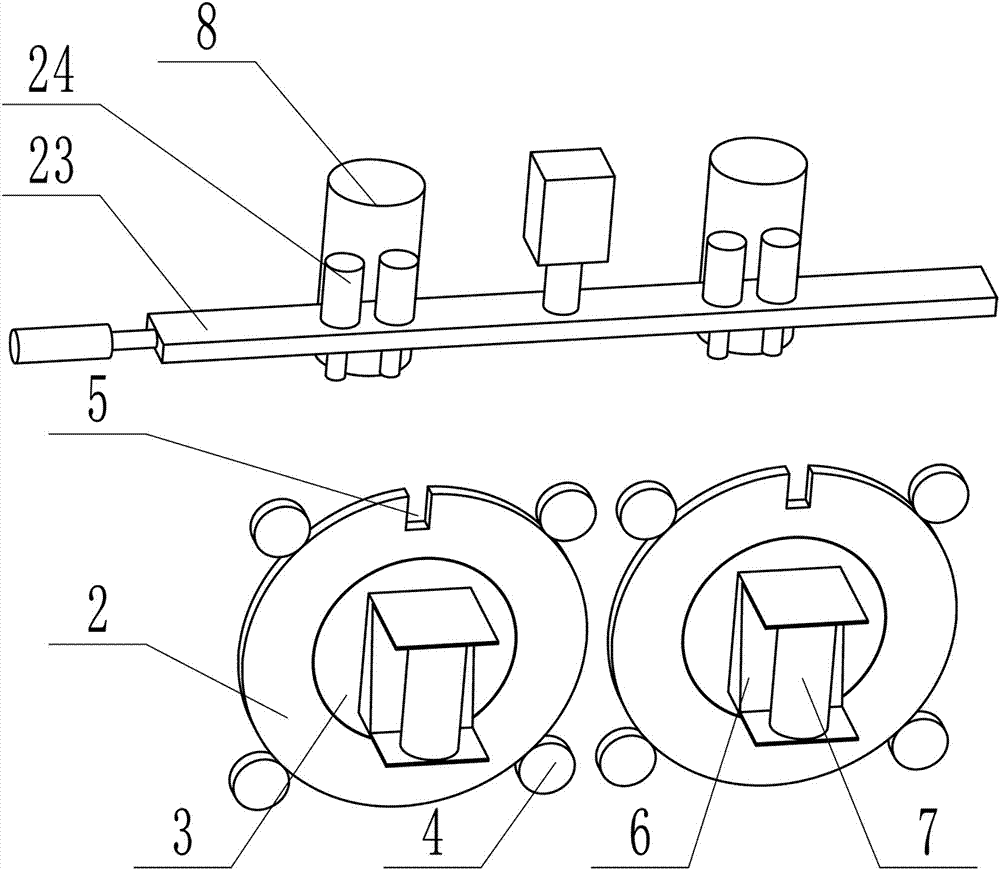

[0032] Embodiment 2: as attached image 3 As shown, on the basis of Embodiment 1, only the structure of the wire pulling device is changed, and the wire pulling device includes a connecting plate 23 capable of moving in the horizontal and vertical directions, and is arranged on the connecting plate 23 for carrying out wire meshing. Limiting cylinder group 24, the position of the cylinder group 24 corresponds to the position of the gear plate 2, the cylinder group 24 includes two cylinders, the cylinder body of the cylinder is arranged on the upper side of the connecting plate, and the cylinder of the cylinder The rod passes through the connecting plate on the underside of the connecting plate.

[0033] In the initial state, the slots 5 of the gear plate 2 are all vertically upward.

[0034] When this embodiment is in use, the cylinder rods of the cylinder group 24 stretch out from the connecting plate 23, and the space between the cylinder rods of the two cylinders forms a sp...

Embodiment 3

[0035] Embodiment 3: as attached Figure 4 As shown, on the basis of Embodiment 1, the structure of the wire pulling device and the rotating device is changed. The rotating device is arranged in more than one group in sequence and the setting direction is the same as that of the screwing device 1. Each group of the rotating device It includes four gear discs 2 and a driving device for driving the gear discs 2 to rotate. The four gear discs are arranged in a rectangular array, and the outer edge of each of the gear discs 2 is provided with a device for clamping the first wire feeding device. 8 provides two mesh slots 5, the slots 5 are two, and the angle between the two slots 5 and the center line of the corresponding gear plate 2 is 90°. The four gear plates 2 are defined as a gear plate 2a, b gear plate 2b, c gear plate 2c and d gear plate 2d, and are arranged at four vertices of the quadrilateral in turn. Under the action of the dialing device, the first The mesh wire of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com