A ground wire bending platform

A grounding wire and platform technology, applied in the field of bending devices, can solve problems affecting construction efficiency, engineering quality, etc., and achieve the effects of avoiding production efficiency reduction, reducing acquisition cost, and improving molding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

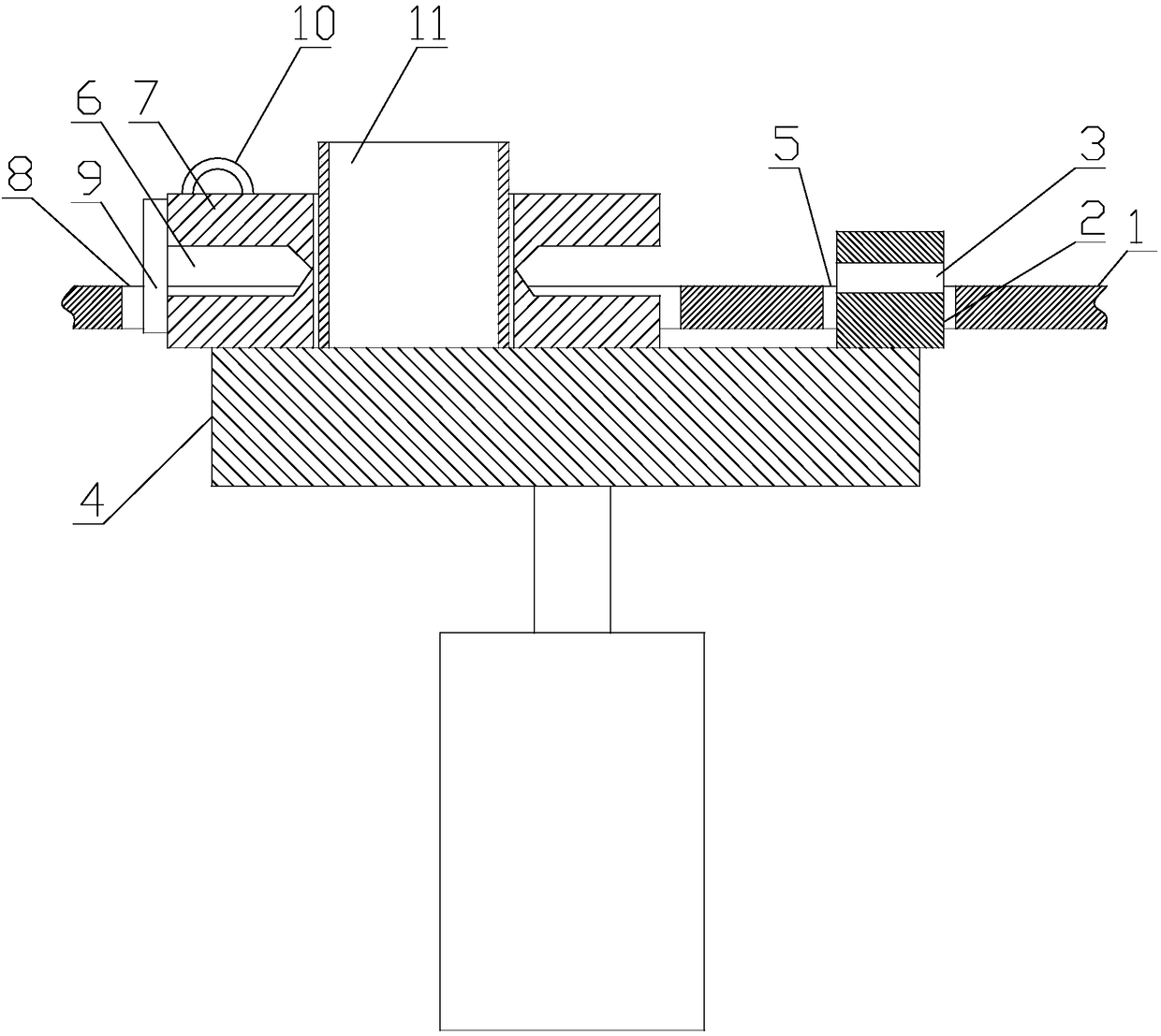

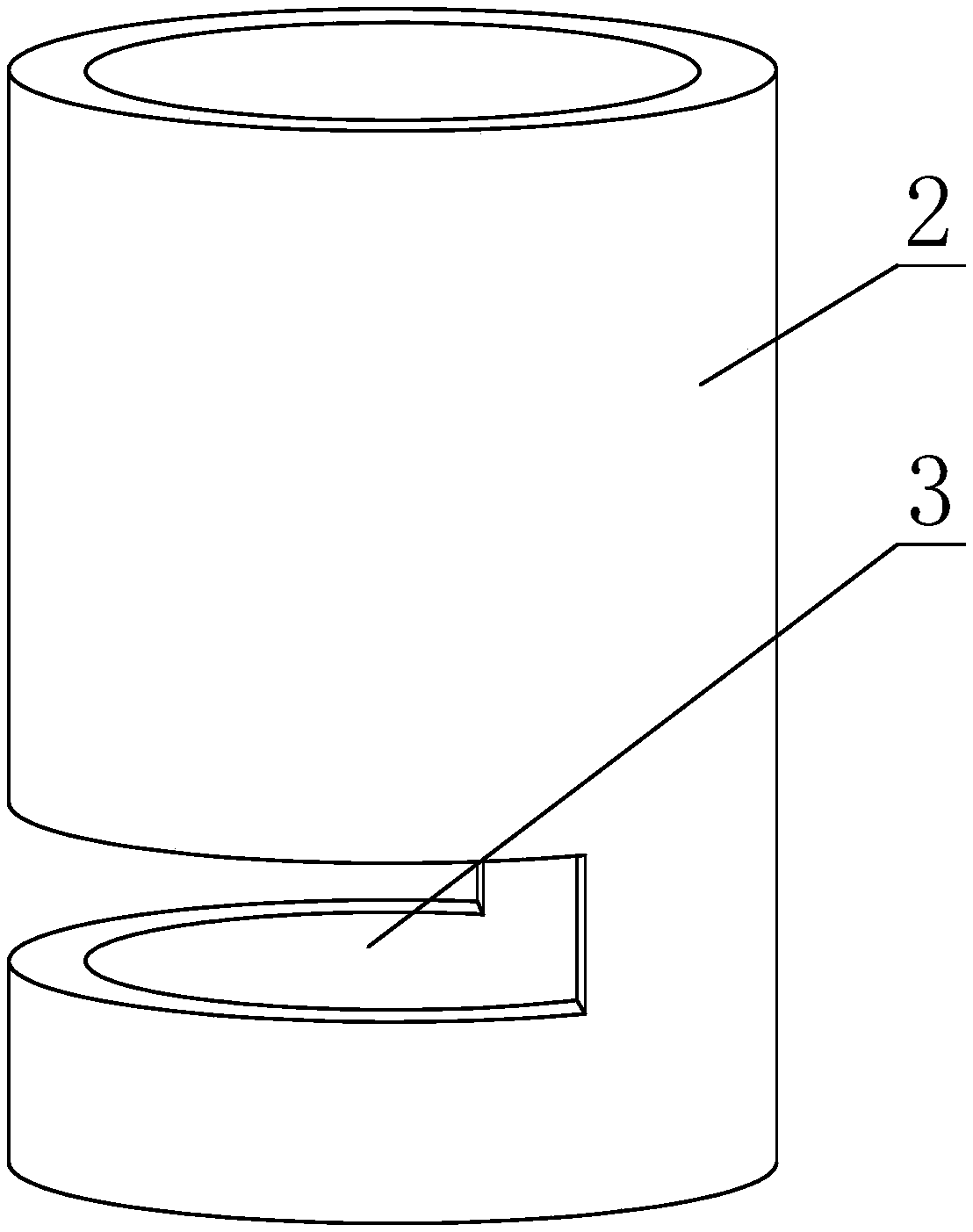

[0027] Such as figure 1 and figure 2 As shown, a grounding wire bending platform includes a platform plate 1, a first gear lever 2, a rotating disk 7 and a rotating shaft 11. The rotating disk 7 can rotate on the axis of the rotating shaft 11 as the rotating shaft 11, and the rotating disk 7 is also provided with An annular ring groove 6, the axis of the ring groove 6 is in line with the axis of the rotating shaft 11, and the turntable 7 and the first gear rod 2 protrude from the second through hole 8 and the first through hole 5 to the platform plate respectively 1, the notch 3 and the ring groove 6 can be fully or partially exposed on the upper side of the platform plate 1;

[0028] A second gear rod 9 is also fixed on the turntable 7, and there is a gap for the flat rod to pass between the second gear rod 9 and the groove bottom of the ring groove 6;

[0029] A notch 3 is also provided on the side of the first gear lever 2;

[0030] The platform plate 1 is also provided...

Embodiment 2

[0035] Such as figure 1 and figure 2 As shown, this embodiment is further limited on the basis of the technical solution provided in Example 1. As a realization solution that is easy to obtain materials on the construction site, the turntable 7 is welded by two neck butt welding flanges, The second gear rod 9 is a rod member welded on the side of the butt welding flange with neck.

[0036] As a specific easy-to-implement connection form, the rotating shaft 11 and the first shift rod 2 are both fixed on the lifting platform 4 , and the rotating disk 7 is provided with a middle hole, and the middle hole is in clearance fit with the rotating shaft 11 .

Embodiment 3

[0038] Such as figure 1 and figure 2 As shown, this embodiment is further limited on the basis of Embodiment 1: for the convenience of confirming the bending degree of the bending part of the flat rod, the surface of the platform plate 1 is also provided with an angle scale for marking the bending angle of the flat rod .

[0039] In order to reduce the weight of this platform, it is easy to carry, and the work does not depend on other power equipment, it also includes a driving device for driving the lifting table 4 to do lifting movement, the driving device includes a threaded rod and an internal threaded cylinder, and the threaded rod and The internally threaded cylinder is threadedly connected, and the lifting table 4 is fixedly connected with the threaded rod or the internally threaded cylinder. In this solution, by applying an external force to force the threaded rod and the internal threaded cylinder to rotate relative to each other, the components composed of the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com