Technological arrangement and preparation method of minimal-specification tire cord steel wire rods

A technology of cord steel and specifications, which is applied in the field of process layout and preparation of extremely small-sized cord steel wire rods, and can solve the problems of high failure rate of small-sized cord steel, manpower, machinery, equipment consumption, and inability to produce cord steel, etc. Achieve the effect of improving the economic efficiency and competitiveness of the enterprise, increasing the operating rate, and reducing production failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

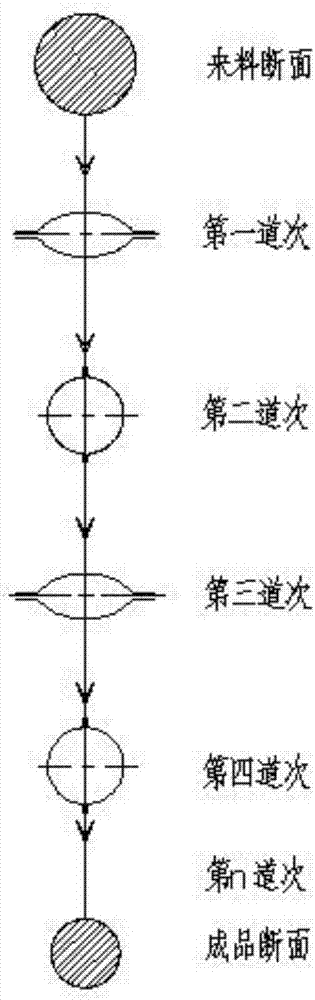

[0030] as the picture shows, figure 1 It is the process layout diagram of the first embodiment of the very small size cord steel wire rod of the present invention; it includes a high-speed wire rod production line and a very small size rolling production line arranged after the high speed wire rod production line, and the very small size rolling production line includes a multi-roll rolling mill unit. The high-speed wire rod production line of this embodiment includes the following process layout, wherein 1 is a heating furnace; 2 is a 6-stand rough rolling unit; 3 is a cutting head flying shear; 7 is the water tank after pre-finishing rolling; 8 is the cutting head flying shear; 9 is the 8-stand finishing rolling unit; 10 is the water tank after finishing rolling; 13 is the pinch roll and laying machine; 14 is the Stelmo air-cooled line; 15 is the coil collection station; the very small size rolling production line includes a multi-roll mill unit 16 and a cord steel cutting ...

Embodiment 2

[0047] figure 2It is the process layout diagram of the first embodiment of the very small size cord steel wire rod of the present invention; it includes a high-speed wire rod production line and a very small size rolling production line arranged after the high speed wire rod production line, and the very small size rolling production line includes a multi-roll rolling mill unit. The high-speed wire rod production line of this embodiment includes the following process layout, wherein 1 is a heating furnace; 2 is a 6-stand rough rolling unit; 3 is a cutting head flying shear; 7 is the water tank after pre-finishing rolling; 8 is the cutting head flying shear; 9 is the 8-stand finishing rolling unit; 10 is the water tank after finishing rolling; 11 is reducing and sizing; 12 is reducing and sizing 13 is the pinch roll and laying head; 14 is the Stelmo air-cooled line; 15 is the coil collection station; the very small size rolling production line includes multi-roll mill unit 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com