Large production line of green brick tea and production method

A green brick tea and production line technology, which is applied in tea processing before extraction, etc., can solve the problems of high labor intensity, uneven artificial coating, cumbersome procedures, etc., and achieve the effects of improving product quality, saving time and cost, and increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

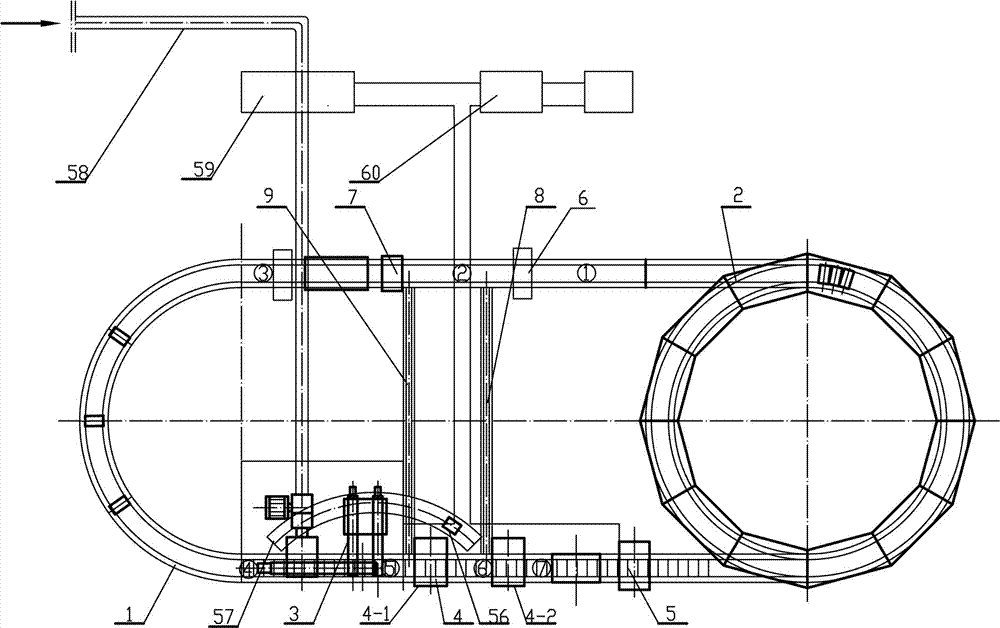

[0065] Such as figure 1 As shown, a large-scale green brick tea production line includes an annular conveying track 1 and a spiral conveying track 2. An automatic tea batching and unloading device 3, a pressing device 4, and a lifting device 5 are arranged on one side of the annular conveying track 1; One side is arranged with mold head dismantling device 6, green brick tea ejector device 7, mold head dismantling mechanism 6, green brick tea ejector device 7 are respectively connected with mold head conveyor belt 8, panel cleaning conveyor belt 9, mold head conveyor belt 8, The other end of the panel cleaning conveyor belt 9 is connected with the circular conveyor track 1 before and after the pressing device 4 . Drive equipments such as motor, hydraulic cylinder, air cylinder are arranged in these devices, so electric cabinet 59, hydraulic station 60 and air pressure system are arranged on one side of this production line, all are controlled by unified controller.

[0066] sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com