Muffin preblend powder and application thereof

A technology for ready-mixed flour and muffins, which is applied to the field of ready-mixed muffins, can solve the problems of different colors of slurry heating time patterns, large pores on the surface of muffins, different printing sequences, etc., and achieve a clear printing pattern. , The surface is delicate and smooth, and the effect is simple to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

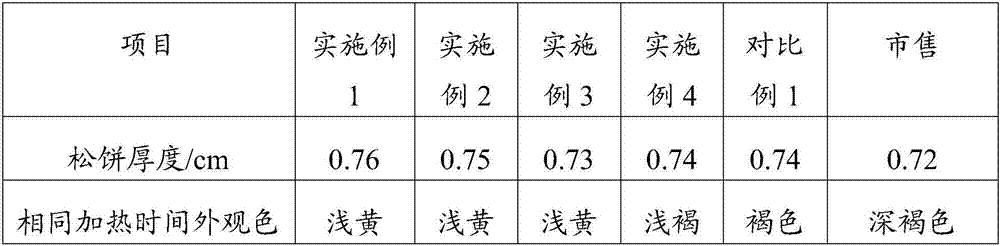

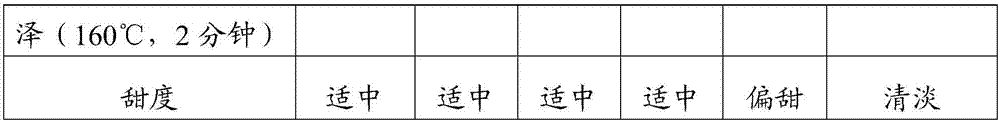

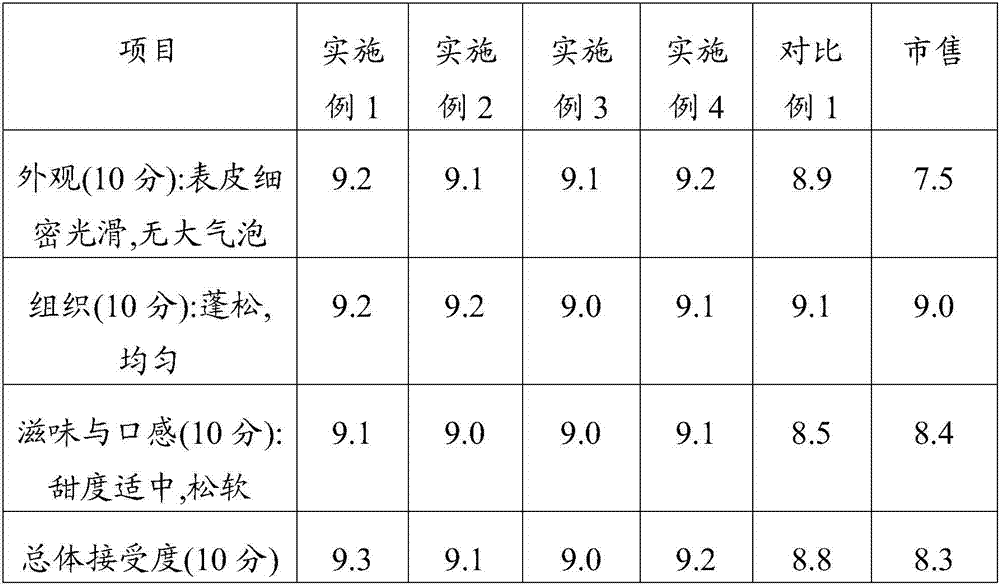

Examples

Embodiment 1

[0031] A muffin premix for 3D printing, in parts by weight, comprising the following raw materials: 63.97 parts of low-gluten wheat flour, 10 parts of sucrose, 16 parts of trehalose, 5 parts of powdered oil, 2 parts of pre-gelatinized modified modified starch, 1 part of polyglycerol fatty acid ester, 0.5 part of xanthan gum, 0.8 part of edible salt, 0.4 part of baking powder, 0.2 part of citric acid, 0.1 part of food flavor, 0.02 part of sucralose, 0.01 part of steviol glycoside.

Embodiment 2

[0033] A muffin premix for 3D printing, in parts by weight, comprising the following raw materials: 54.93 parts of low-gluten wheat flour, 5 parts of sucrose, 20 parts of trehalose, 10 parts of powdered oil, 3 parts of pre-gelatinized modified modified starch, 3 parts of polyglycerol fatty acid ester, 1 part of xanthan gum, 1 part of edible salt, 1 part of baking soda, 0.5 part of citric acid, 0.5 part of food flavor, 0.05 part of sucralose, and 0.02 part of steviol glycoside.

Embodiment 3

[0035] A muffin premix for 3D printing, in parts by weight, comprising the following raw materials: 70 parts of low-gluten wheat flour, 8 parts of sucrose, 12 parts of trehalose, 6 parts of powdered oil, 1 part of pregelatinized denatured starch, 1 part of polyglycerol fatty acid ester, 0.6 part of xanthan gum, 0.6 part of edible salt, 0.2 part of baking powder, 0.3 part of citric acid, 0.2 part of food flavor, 0.01 part of sucralose, and 0.03 part of steviol glycoside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com