Micro limit general switch based on double elastic components

A technology of elastic parts and elastic components, applied in the field of micro-motion limit switches, can solve the problems of poor contact, non-compliance with industry standards, low switch safety factor, etc., and achieve the effect of avoiding aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

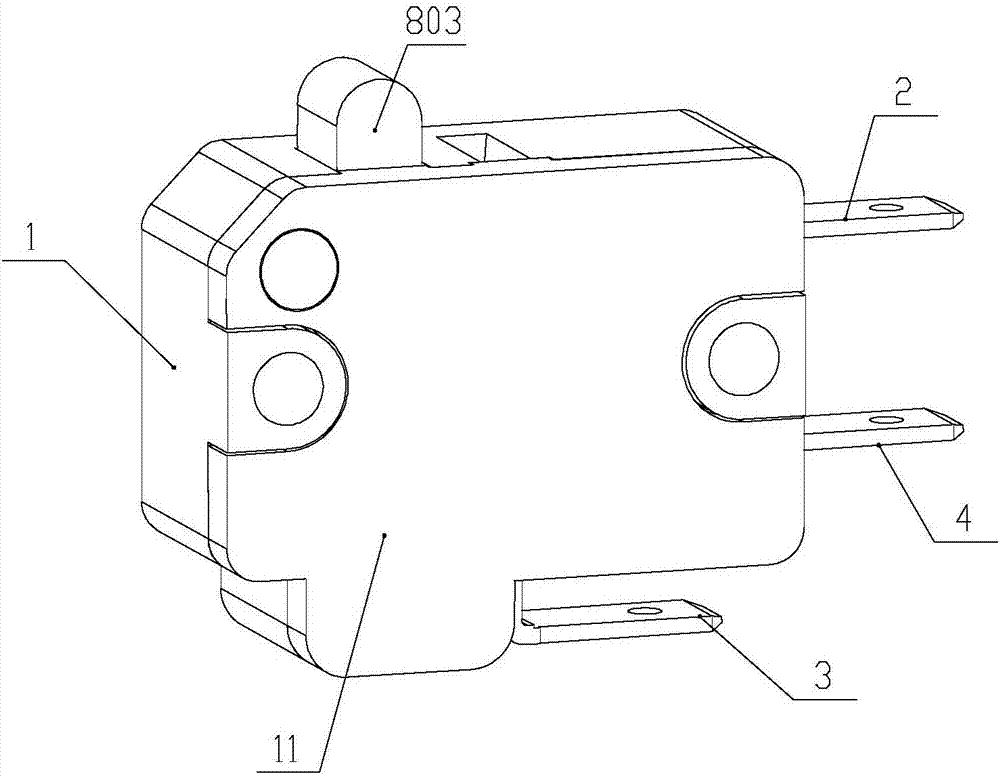

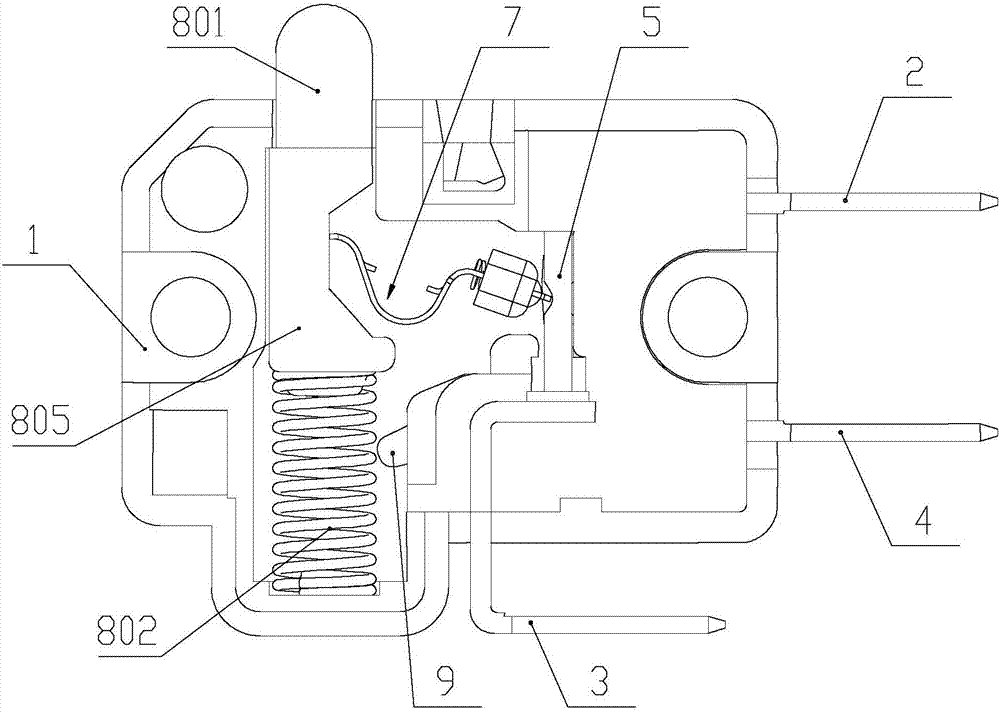

[0043] Such as figure 1 , figure 2 and image 3 As shown, the present invention is a kind of micro-movement limit universal switch based on double elastic parts, which includes a housing 1 and a face cover 11 adapted to the housing 1. The housing is provided with a normally open connector 2, a normally closed Connector 3 , common connector 4 , movable contact piece 5 , guide component 6 , elastic component 7 and trigger component 8 . One end of the normally open connector 2 and the common connector 4 protrudes from the same side of the housing as a plug terminal, and the other end of the normally open connector 2 and the common connector 4 is located in the housing 1, and the normally open connector 2 has a normally open contact for conducting or disconnecting with the movable contact piece 5. One end of the normally closed connector 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com