Large effective area optical fiber

A technology of effective area and optical fiber, which is applied in the direction of cladding optical fiber, multi-layer core/clad optical fiber, light guide, etc., can solve the problems of increasing optical fiber loss, manufacturing difficulty, and high manufacturing cost, so as to reduce complexity and cost, reduce Loss, effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0025] Such as figure 1 As shown, the optical fiber with large effective area of the present invention includes a core layer 1 , an inner cladding layer 2 , an outer cladding layer 3 , an inner coating layer 4 and an outer coating layer 5 from the inside to the outside. The core layer 1 and the inner cladding layer 2 surrounding the core layer 1 are made of synthetic quartz (SiO 2 ) as the base and dopant added, the outer cladding 3 surrounding the inner cladding 2 is pure SiO 2 . The main component of the inner coating layer 4 surrounding the outer cladding layer 3 and the outer coating layer 5 surrounding the inner coating layer 4 is a photocurable resin. The effective area in the present invention refers to the effective area at a wavelength of 1550 nm.

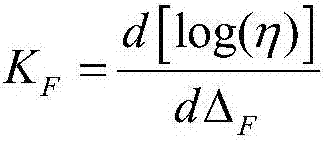

[0026] figure 2 is the refractive index profile of a large effective area fiber. The horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com