Construction device of non-reinforced spread foundation and construction method of rigid and flexible dual composite foundation

A technology for expanding foundations and construction devices, which is applied in basic structure engineering, soil protection, construction, etc. It can solve the problems of unusable bearing capacity, inapplicability, and low bearing capacity of natural foundations, so as to improve the compactness and bearing capacity, Reduce soil moisture content and facilitate construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

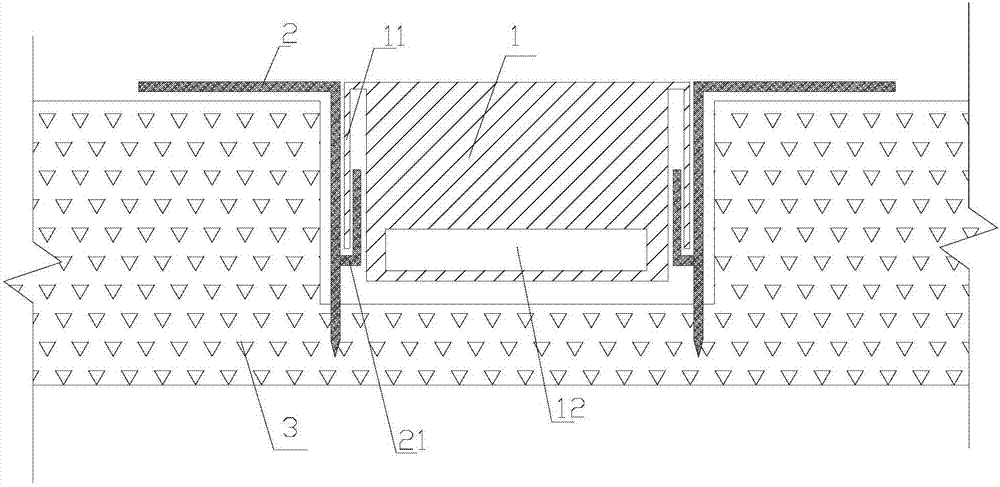

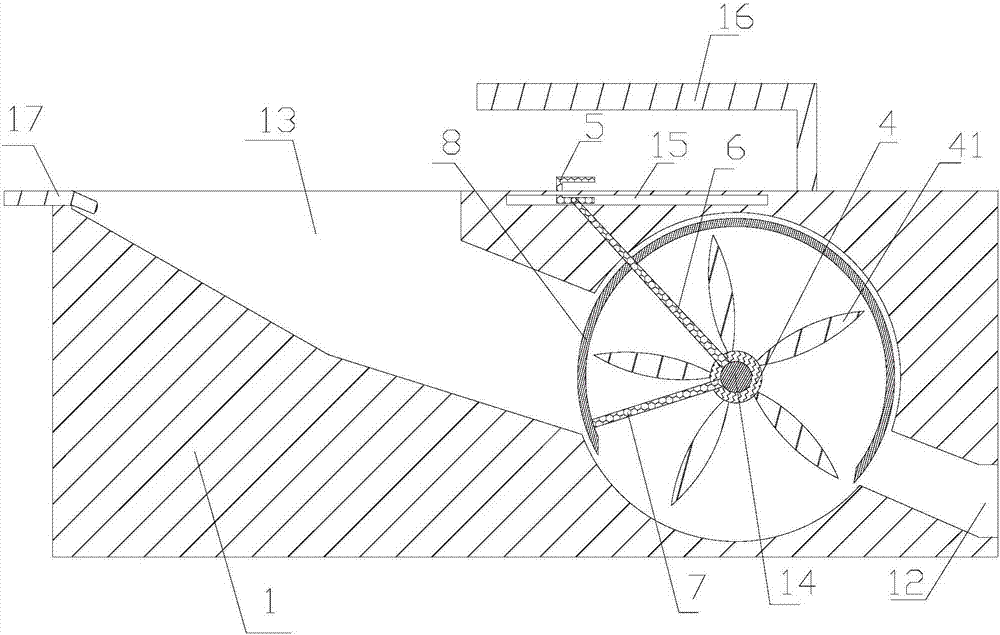

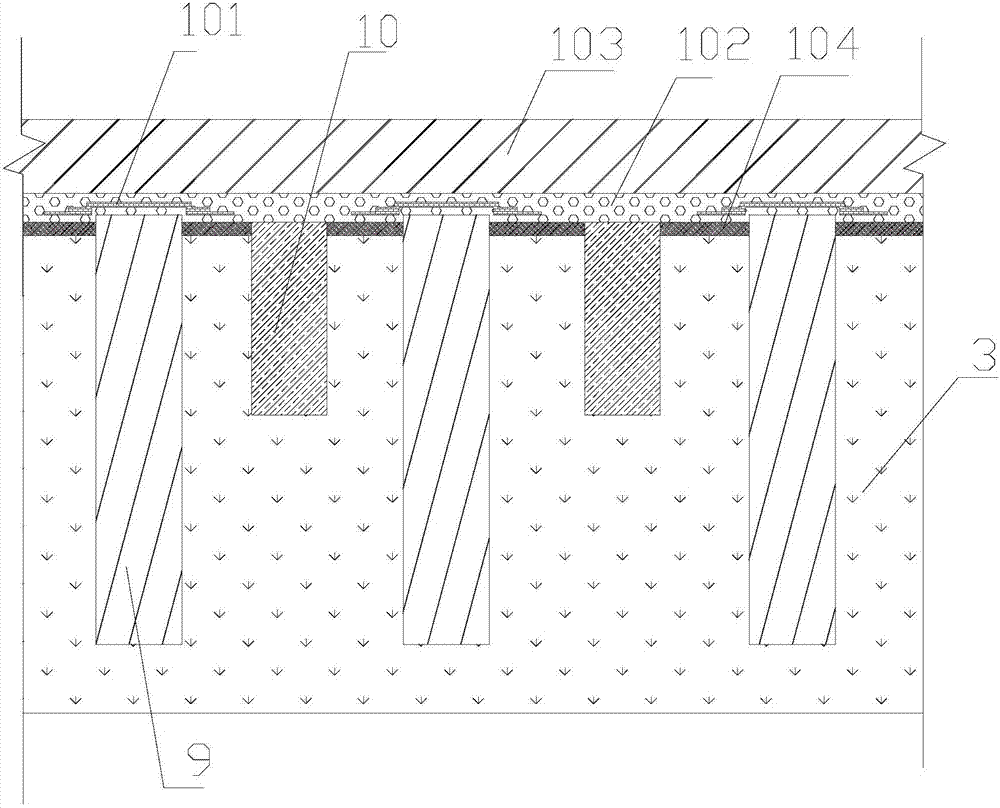

[0022] The present invention proposes a non-reinforced extended foundation construction device, which includes a device body 1 and a prefabricated L-shaped insert 2. The prefabricated L-shaped insert 2 is made of the same material as the unreinforced extended foundation 104, that is, rubble concrete, lime soil Prefabricated the L-shaped board 2 by mixing with triadic soil, etc., the L-shaped board 2 is composed of a first board and a second board connected vertically to form an L-shape, the first board is placed horizontally when in use, and the second board A tip is provided at its end, through which the L-shaped inserting plate 2 is directly inserted into the soil between the piles 3, and the depth o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com