A water cup device

A water cup and trough technology, applied in decorative arts, carving and other directions, can solve the problems of low work efficiency, inconvenient use, increased cost, etc., and achieve the effect of improving the stability of front and rear movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

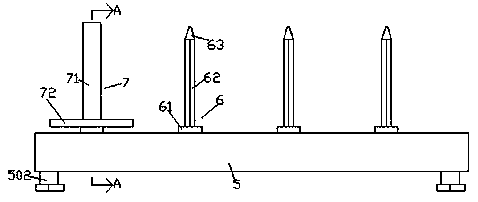

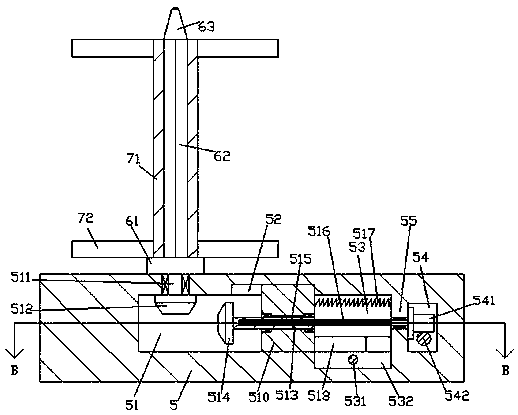

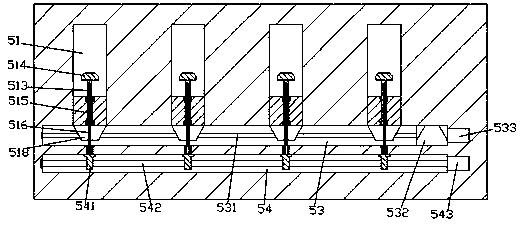

[0021] Such as Figure 1-Figure 6 As shown, a water cup device of the present invention includes a frame body 5 and rotating elements 6 equally distributed on the top end surface of the frame body 5 at equal intervals. The bottom of the frame body 5 is provided with an internal screw hole 501, and the internal screw hole 501 is equipped with a stud 502, by adjusting the stud 502 up and down, the frame body 5 can be conveniently placed on the uneven ground, and the frame body 5 below each of the rotating elements 6 is provided with a front side Extended tooth cavity 51, the front side of the tooth cavity 51 is connected with the first groove body 53 extended from left to right, and the frame body 5 on the front side of the first groove body 53 is provided with a second groove body 54 A separation plate 55 is provided between the first tank body 53 and the second tank body 54, and a guide groove 52 is provided on the inner top of each first tank body 53, and each guide groove 52...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com