Roller with Magnetic Belt

A coiler and magnetic technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problem of unfavorable coiling, difficult coiling of thin strips, and increasing the distance between the center of the flying shear and the center of the double coiler, etc. problem, to achieve the effect of reducing the occupied length and shortening the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The details of the present invention can be understood more clearly with reference to the accompanying drawings and the description of specific embodiments of the present invention. However, the specific embodiments of the present invention described here are only for the purpose of explaining the present invention, and should not be construed as limiting the present invention in any way. Under the teaching of the present invention, the skilled person can conceive any possible modification based on the present invention, and these should be regarded as belonging to the scope of the present invention.

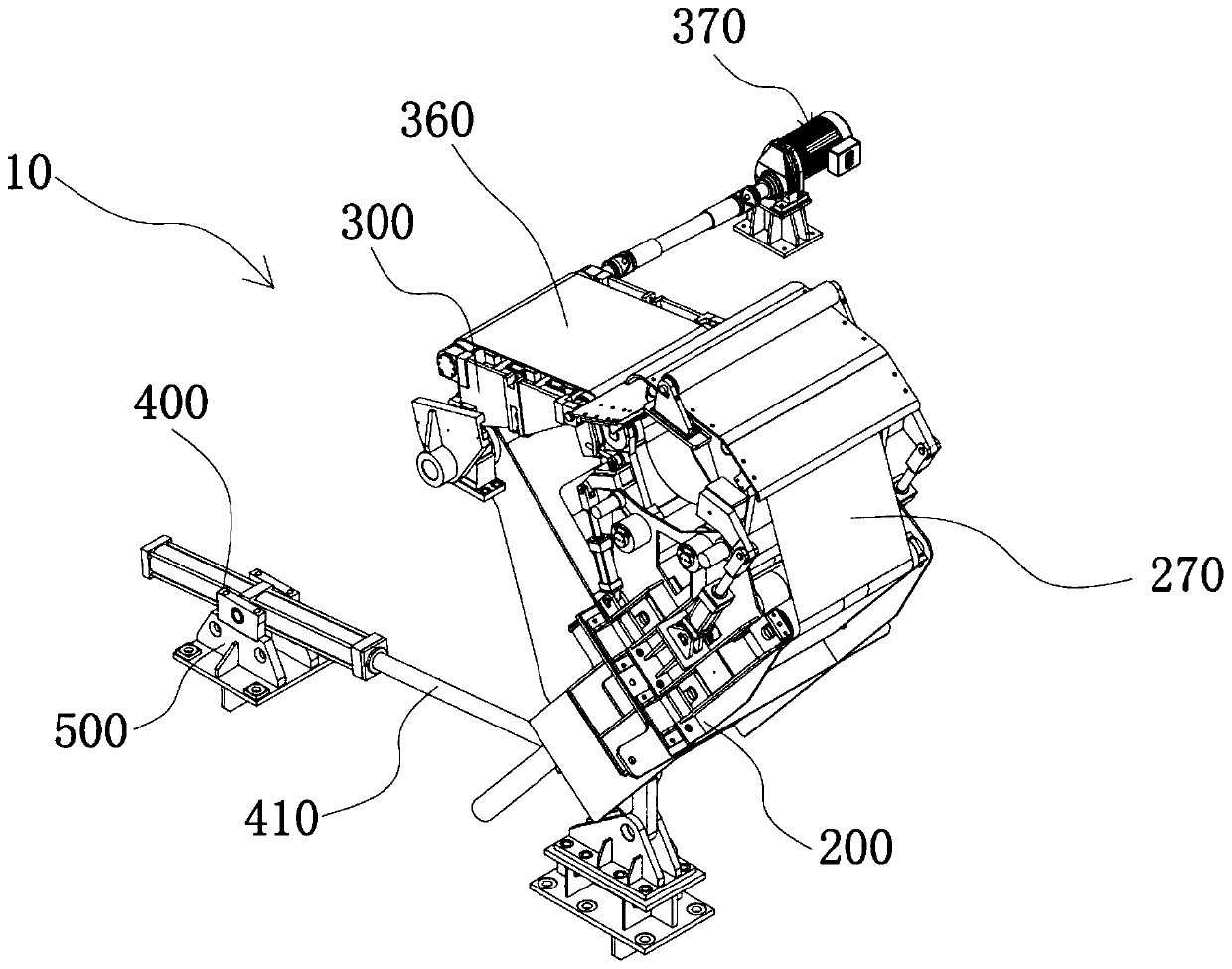

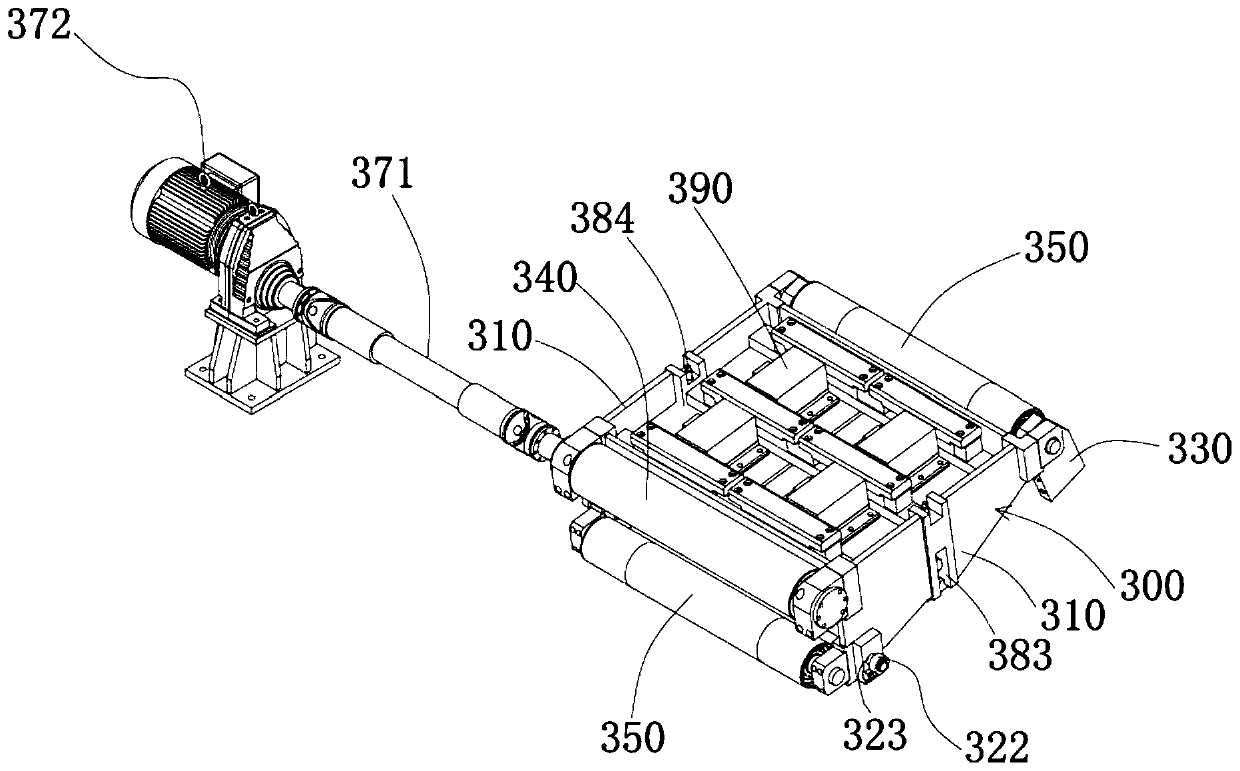

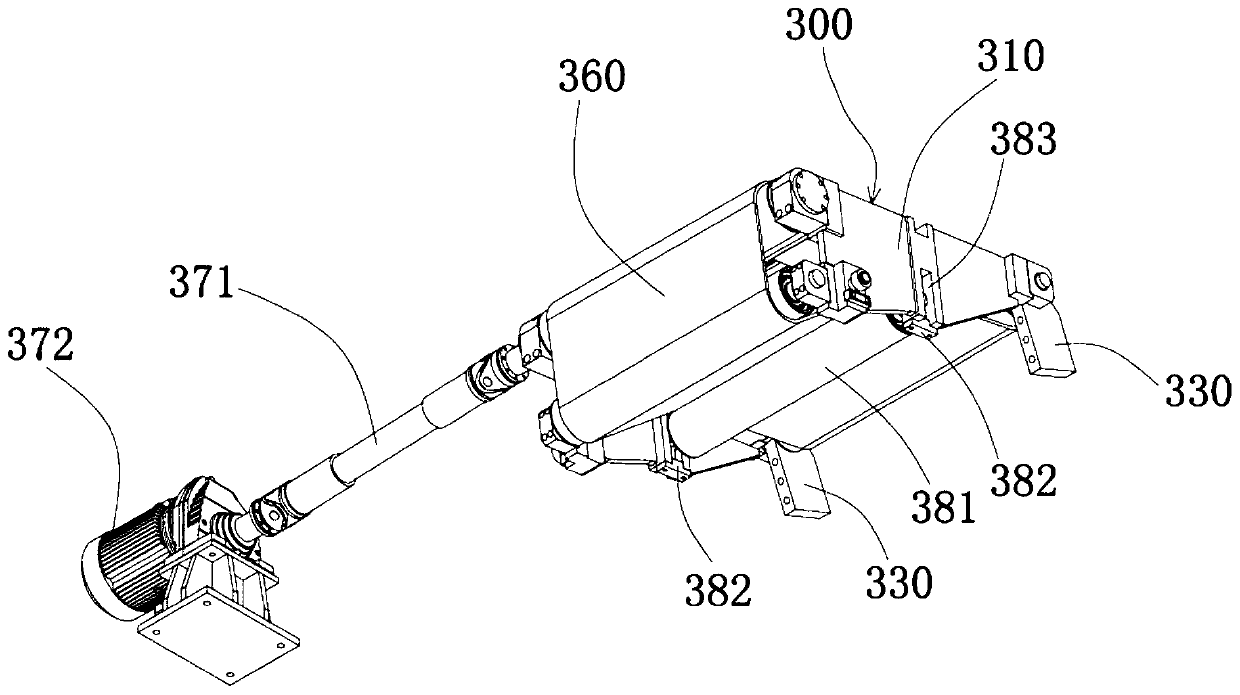

[0056] Please refer to Figure 1 to Figure 8 , the present invention proposes a winding aid 10 with a magnetic belt, the winding aid 10 with a magnetic belt at least includes a rotating shaft 100, a winding aid frame 200 and a magnetic belt frame 300, the rotating shaft 100 is arranged horizontally, and the winding aid The frame body 200 is V-shaped with an upward openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com