One-piece drilling and seeding machine

A seeder, an integrated technology, applied in the field of integrated perforating seeders, can solve the problems of lowering sowing quality, seeds falling out of the pit, increasing sowing time, etc., so as to improve sowing quality and efficiency, low manufacturing cost and simplification The effect of the mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

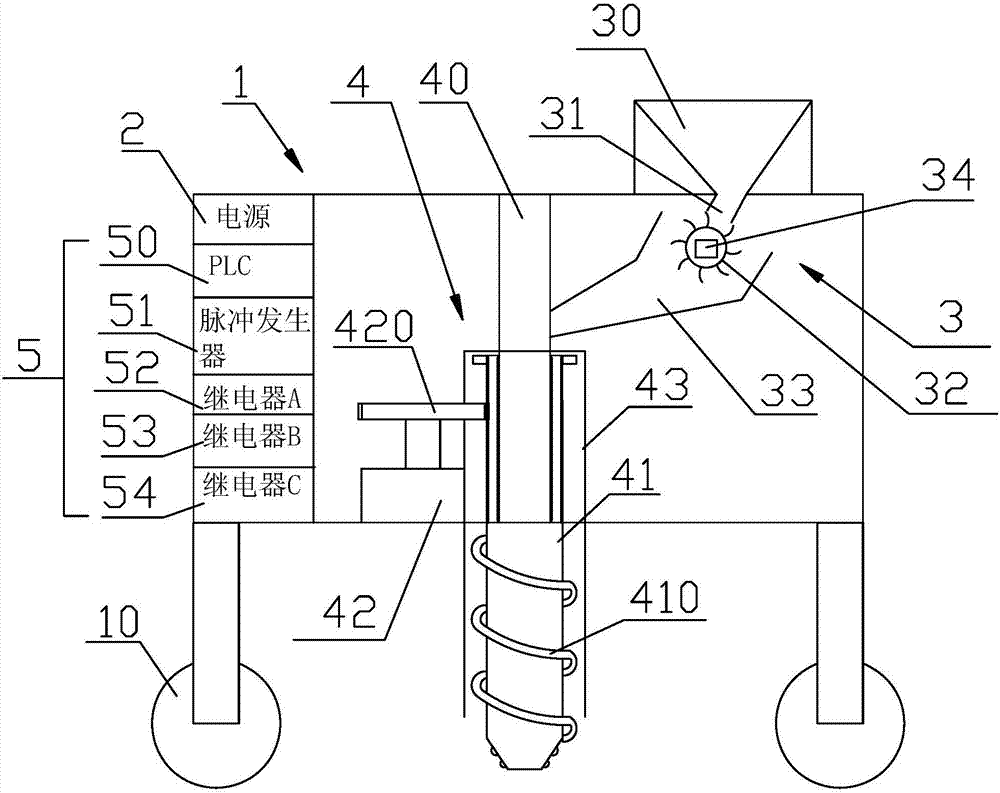

[0031] refer to figure 1 with figure 2 The one-piece perforating seeder shown mainly includes a walking trolley 1 on which a power supply 2 , a seed flow control mechanism 3 , a punching device 4 and a control device 5 are respectively installed.

[0032] The walking trolley 1 is generally in the shape of the top, and its bottom four corners are symmetrically provided with rollers 10. In this embodiment, the power supply 2 adopts a 24V rechargeable battery, which is detachably installed on the walking trolley 1.

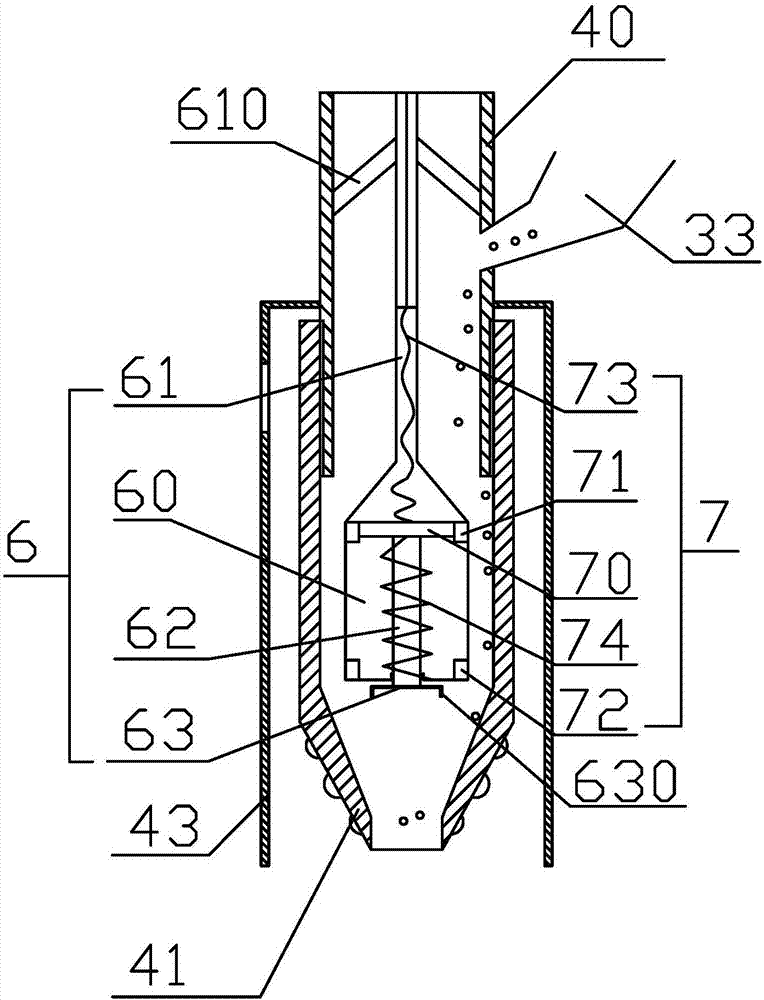

[0033] The drilling device 4 mainly includes a fixed shaft 40, a rotary drill rod 41, and a drill rod motor 42 that drives the rotary drill rod 41 to rotate, such as figure 1 As shown, the fixed shaft 40 is vertically arranged at a position close to the middle of the traveling vehicle frame 1, its upper end is fixed, the lower end is suspended in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com