System and method for separating and extracting soot generated by coal and biomass

A biomass and soot technology, which is applied in the field of soot systems, can solve the problems of expensive, pure soot particles that cannot be obtained for testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, which are explanations rather than limitations of the present invention.

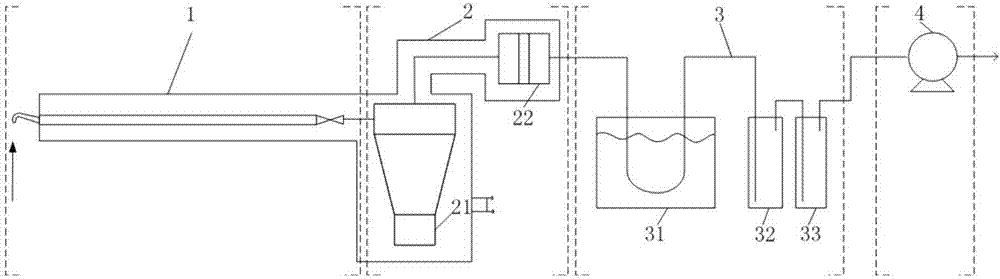

[0035] Such as figure 1 As shown, the present invention is based on the following principle to realize the separation and purification of soot particles in the flue gas of coal and biomass heat utilization. Firstly, a cyclone cutter is used to initially separate the fine particles rich in soot from the coarse particles in the flue gas during sampling, and the purpose of removing the tar in the flue gas is achieved by heating the flue gas to 250-350°C, and the soot filter is used The initial soot was obtained by membrane filtration. Afterwards, the initial soot was dissolved and dispersed in a composite solvent using ultrasound. Part of the soluble coke and inorganic ash particles in the initial soot are dissolved in the solvent. When standing still, the insolub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com