Photonic crystal vibration damping coupling

A technology of phononic crystals and shaft couplings, which is applied in the field of phononic crystal vibration damping couplings, can solve the problems of large coupling structure modification and inapplicability, and achieve the effect of simple structure, convenient processing, and small changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in more detail below in conjunction with accompanying drawing example:

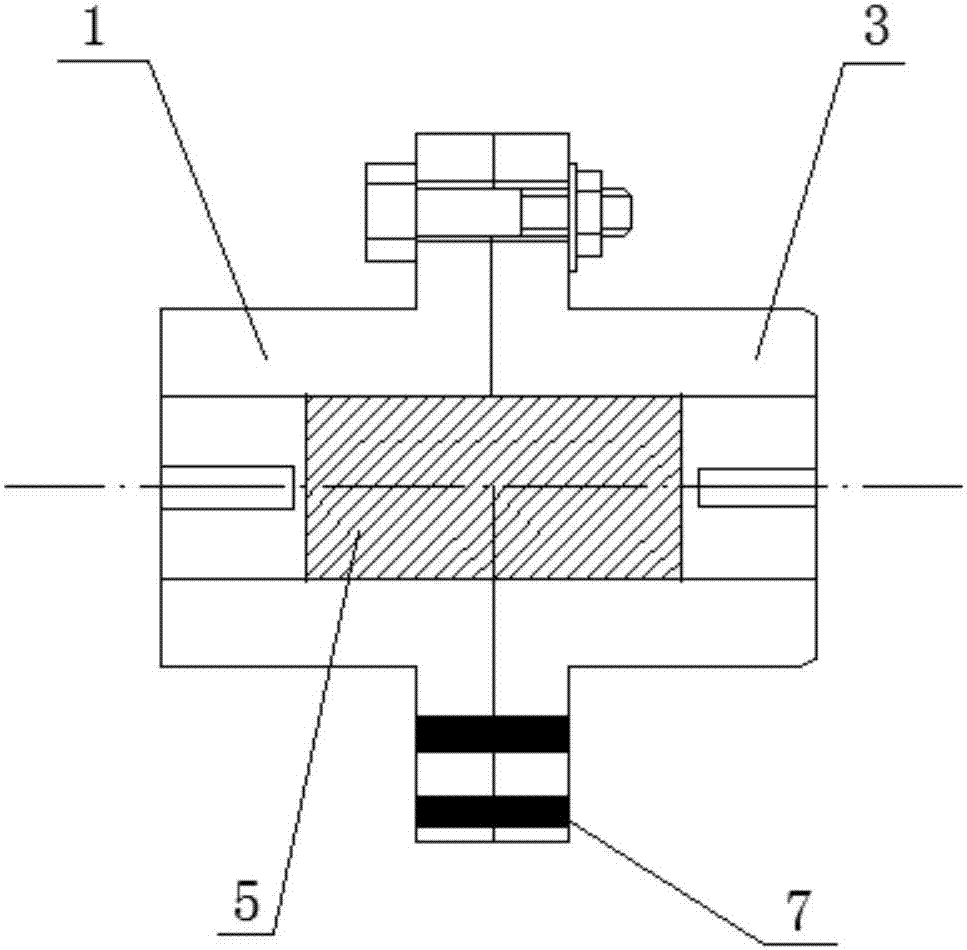

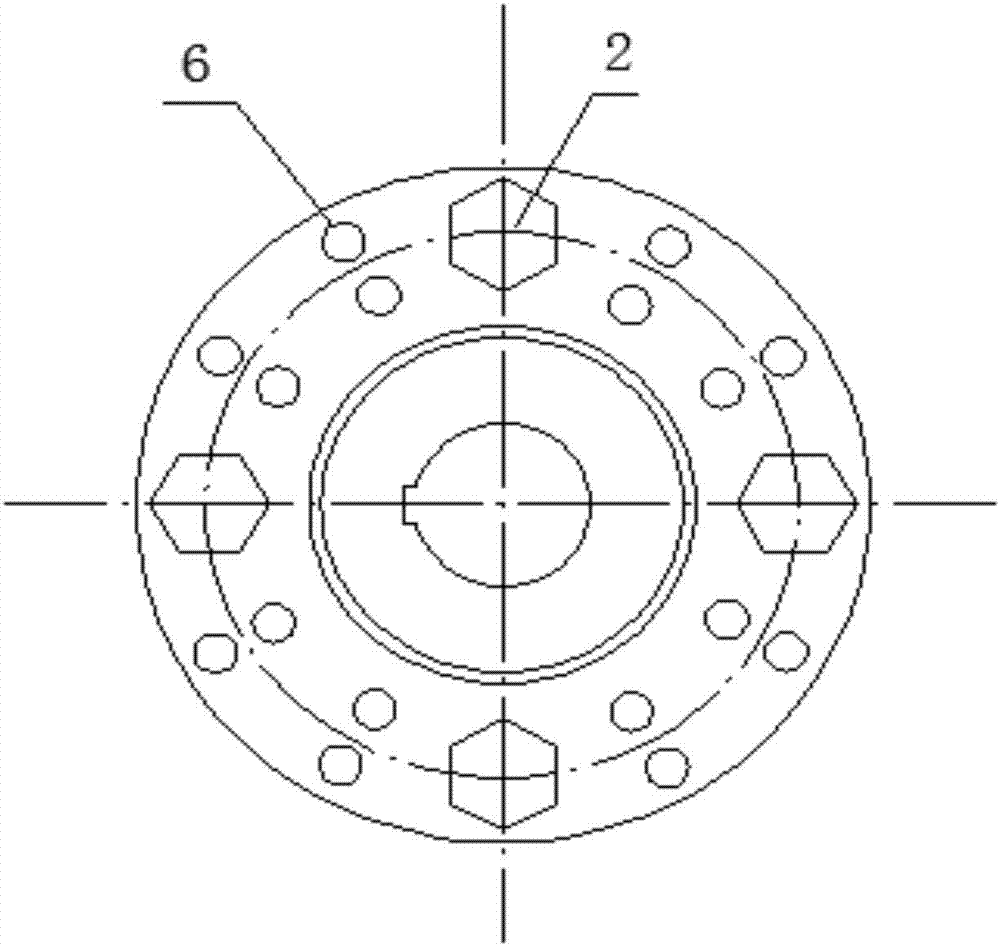

[0021] Such as figure 1 As shown, a phononic crystal vibration-damping coupling includes a first half-coupling 1, a second half-coupling 3, a Bragg-type phononic crystal rod 5 and a local resonance type phononic crystal rod 7 .

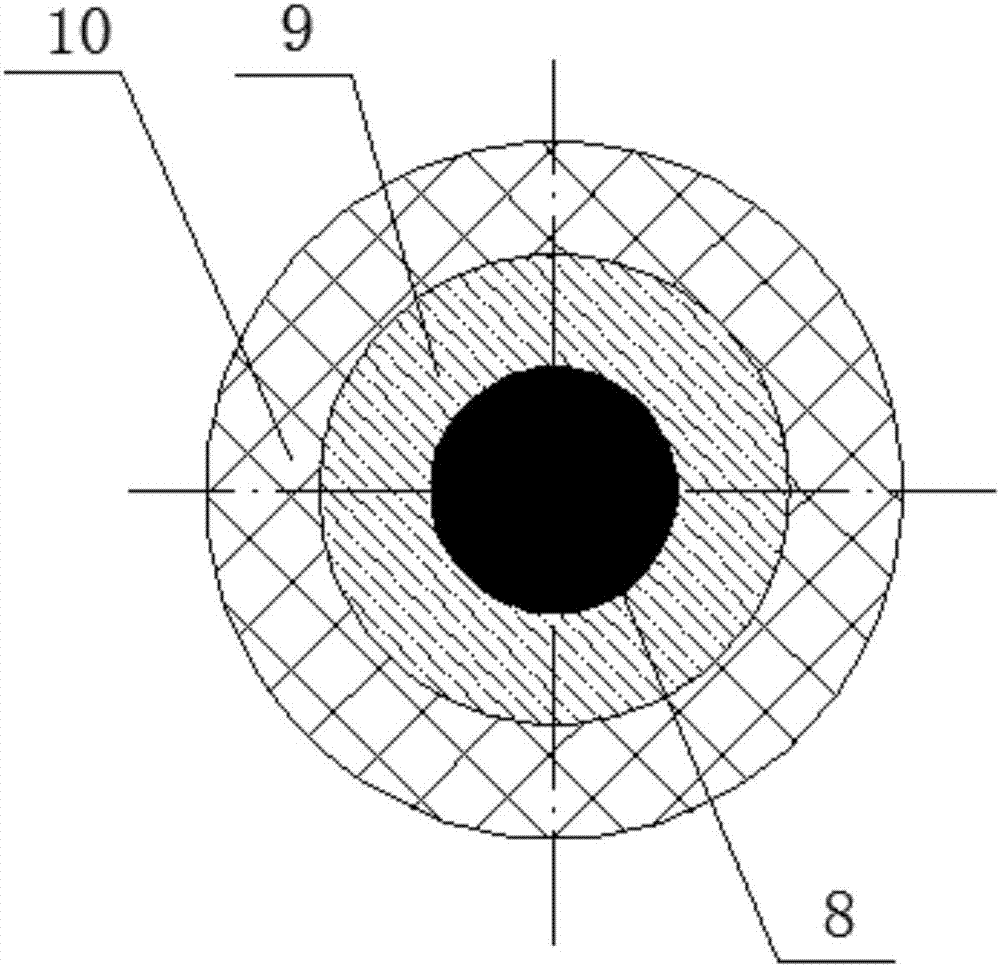

[0022] The Bragg-type phononic crystal rod 5 includes a first vibrator 11 and a second vibrator 12; the Bragg-type phononic crystal rod 5 of the present invention is installed in the shaft hole of the coupling, such as figure 1 shown. The Bragg-type phononic crystal rod 5 is glued to the rotating shaft, and in the process of rigid body resonance, the conversion of longitudinal waves to transverse waves is generated, so that regardless of the incidence of longitudinal waves or transverse waves, the scattered transverse waves are subject to destructive interference, so that the Bragg-type phononic crystal A complete band gap is formed, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com