A clutch device and a method for manufacturing the same

A clutch device and double clutch technology, applied in the direction of clutches, friction clutches, mechanically driven clutches, etc., can solve problems such as welding deformation, large tolerance range, and reduced rotor dimensional stability, and achieve the effect of dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] specific implementation plan

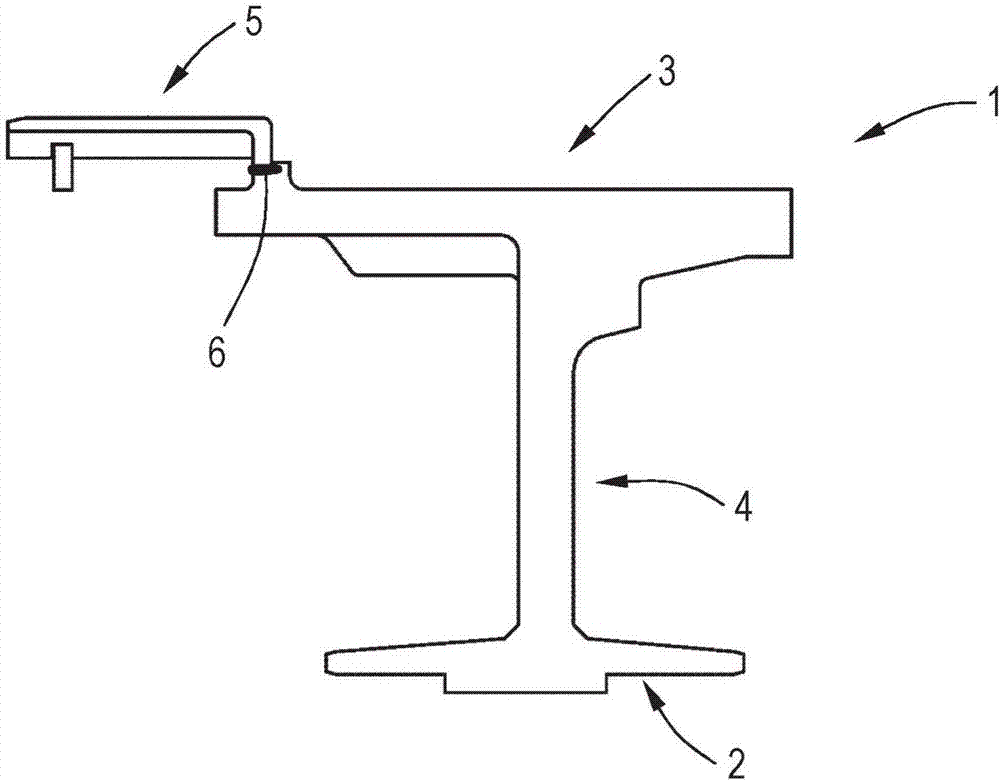

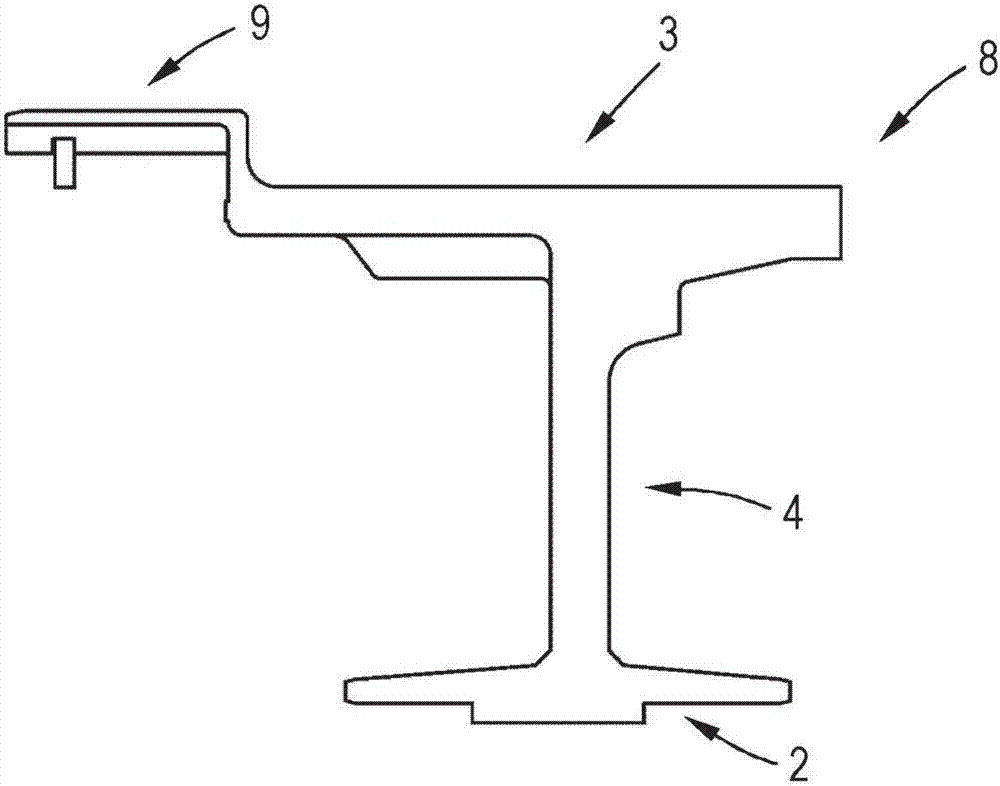

[0025] figure 1 The rotor 1 of a clutch arrangement, not shown in detail, according to a first exemplary embodiment is shown. The rotor 1 has a first section 2 and a second section 3 , which are connected to one another via intermediate webs 4 . In this case, the first section 2 and the second section 3 extend approximately parallel to the axis of rotation of the clutch device. It can be seen that the intermediate web 4 extends approximately perpendicular to the first section 2 and the second section 3 in a cross-sectional view. According to this exemplary embodiment, the rotor 1 is produced by spinning, so that the first section 2 , the second section 3 and the intermediate web 4 are formed in one piece with one another.

[0026] It is clear that the diaphragm holder 5 is connected to the rotor 1 , which according to the exemplary embodiment is connected to the rotor 1 by means of a welding method. The connection between rotor 1 and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com