A power transmission integrated electric wheel

A technology of power transmission and electric wheels, applied in the direction of power devices, motion deposition, vehicle components, etc., can solve problems such as difficult to meet the requirements of vehicle ride comfort, increased degrees of freedom in the internal structure of wheels, changes in wheel parameters, etc., to achieve increased ratio, Ease of maintenance and increase bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

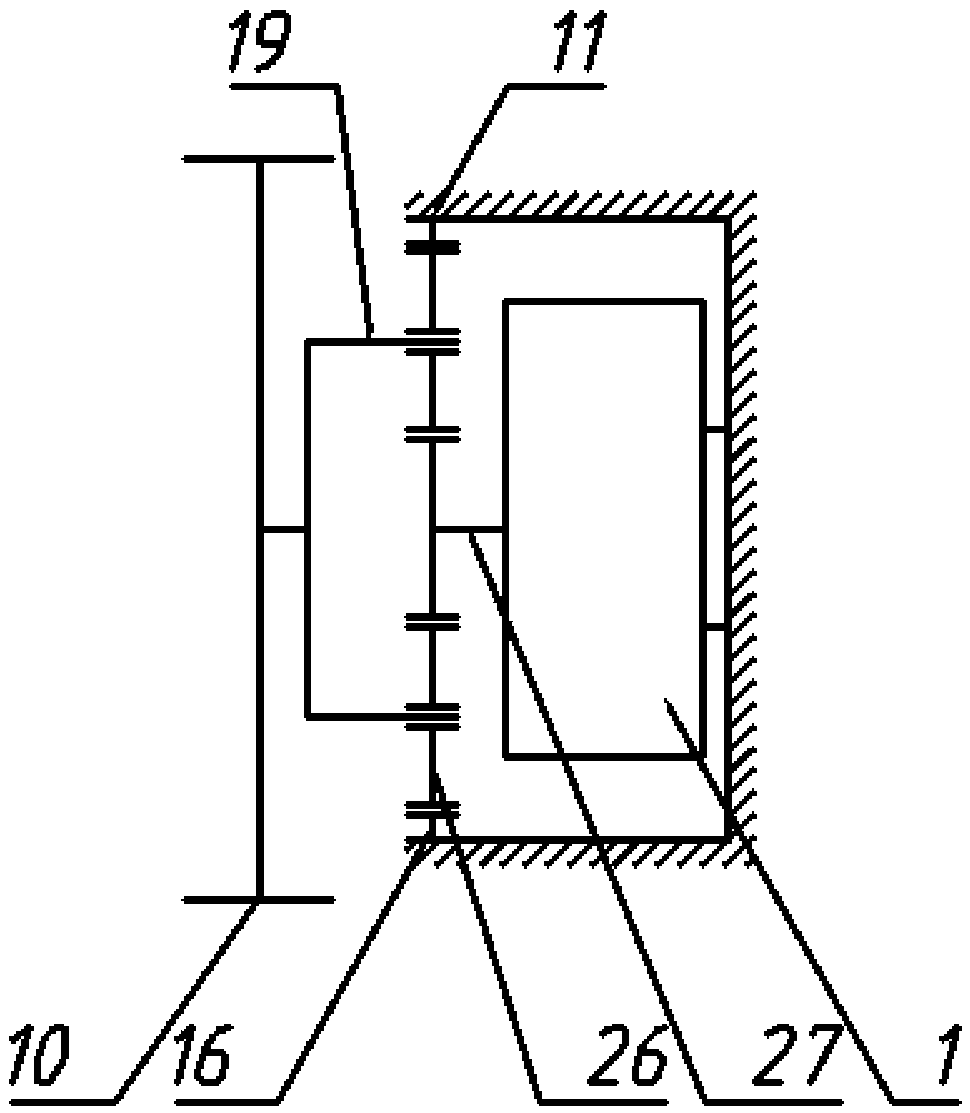

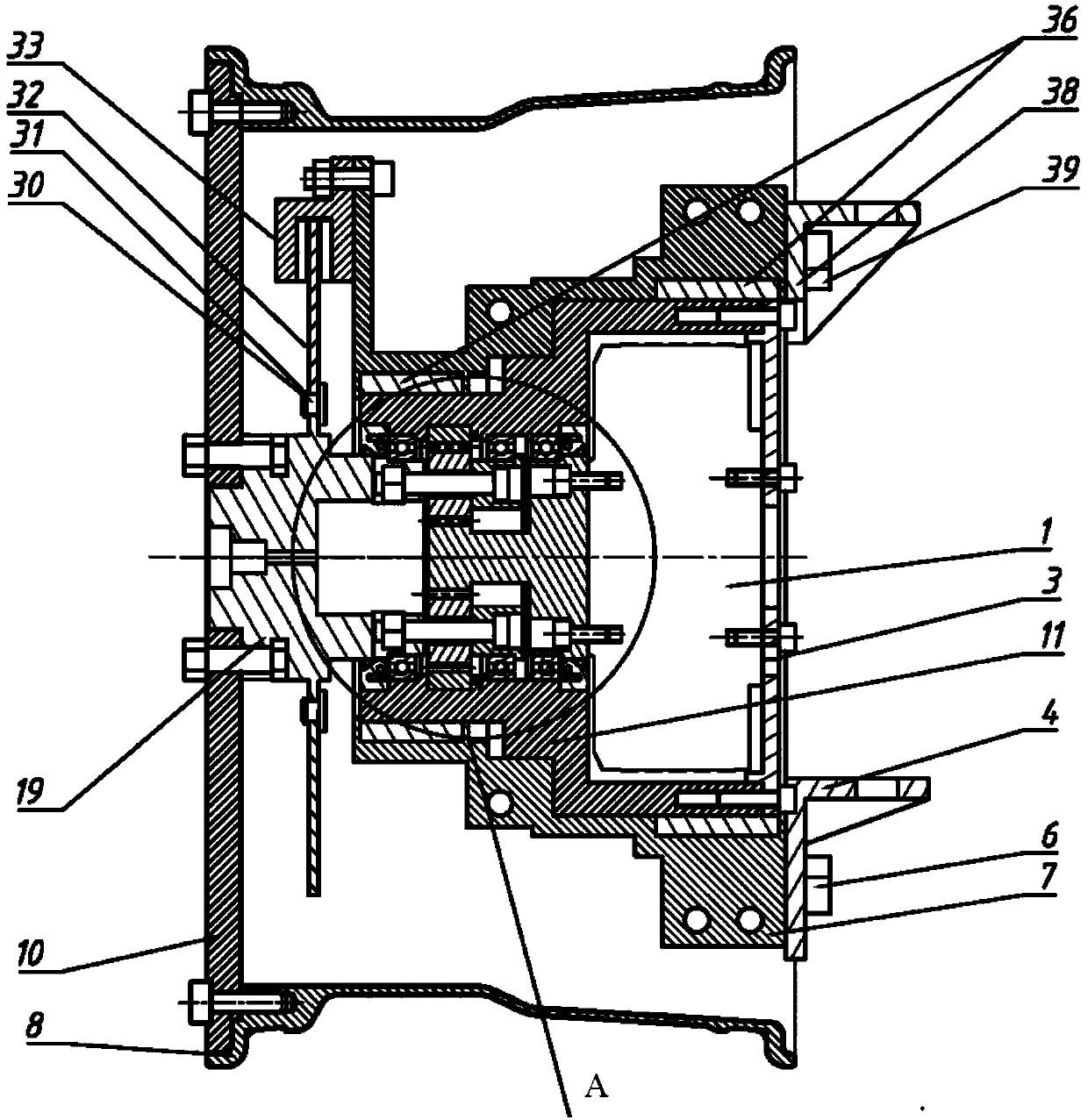

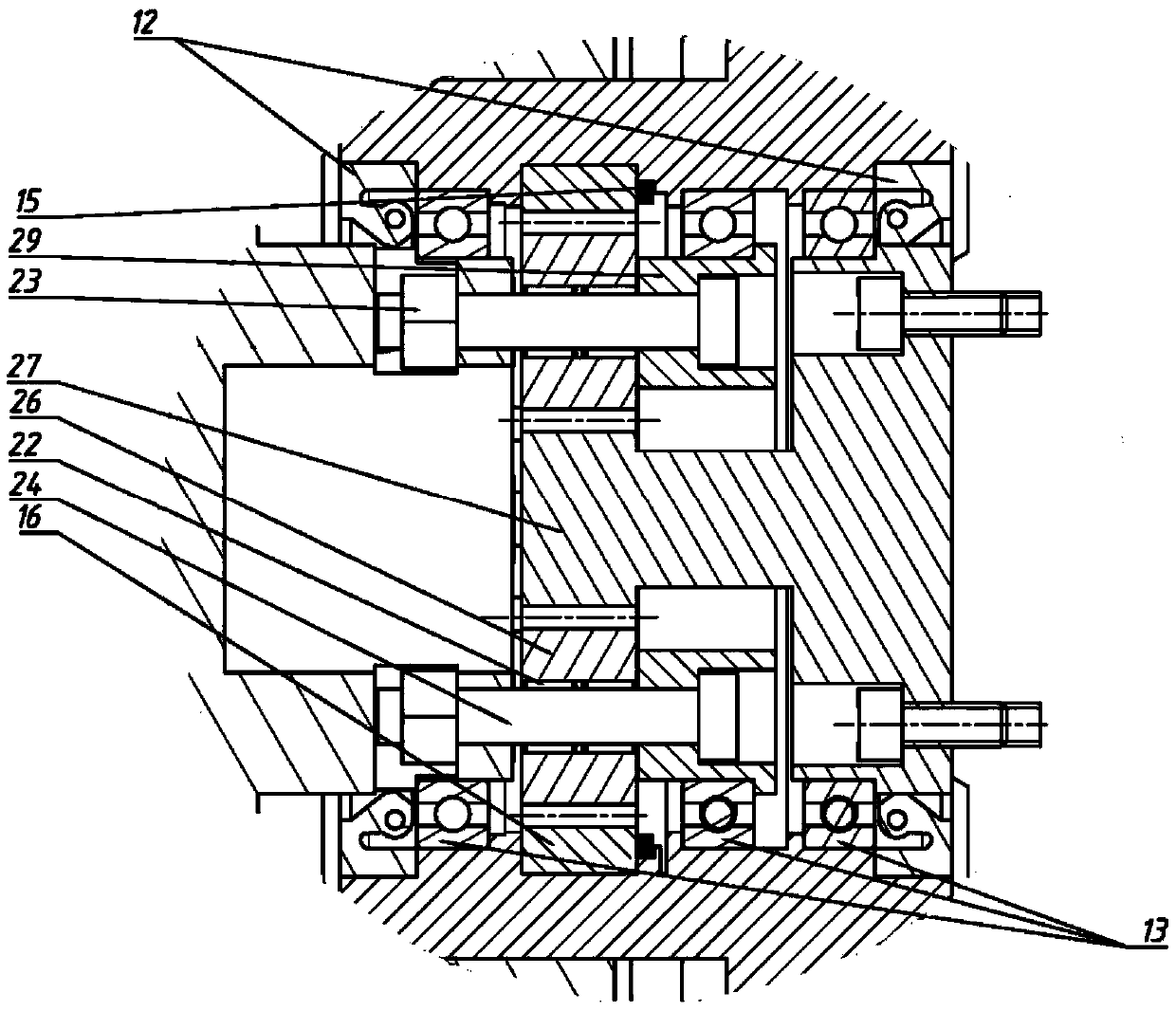

[0024] Such as figure 2 , image 3 As shown, a power transmission integrated electric wheel of the present invention includes: an outer rotor hub motor 1, a planetary reduction gear, a reducer housing, an elastic element 36, a steering column 7, a disc brake, and wheels. The planetary reduction device includes: a sun gear 27 , a planetary gear 26 , a ring gear 16 , a planet carrier 19 , and a planet carrier 2 29 . The reducer housing includes: a housing cover 3 and a housing 11 . The disc brake includes: a brake caliper 33, a brake disc 32, a fixed pin 30, and a snap ring 2 31. The wheel includes: 10 spokes, 8 rims.

[0025] The outer rotor hub motor 1 is located in the housing 11 and consists of an inner stator and an outer rotor. The inner stator is connected to the housing cover 3 through bolts, and the housing cover 3 is connected to the housing 11 through bolts. The side section of the sun gear 27 is I-shaped, and the disc at one end is connected with the outer rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com