Window hole combined mold for prefabricated components

A technology of combining molds and prefabricated components, applied in the directions of ceramic forming cores, ceramic forming mandrels, etc., can solve problems such as inability to realize structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] For ease of understanding, here in conjunction with accompanying drawing, the concrete structure of the present invention and working mode are further described as follows:

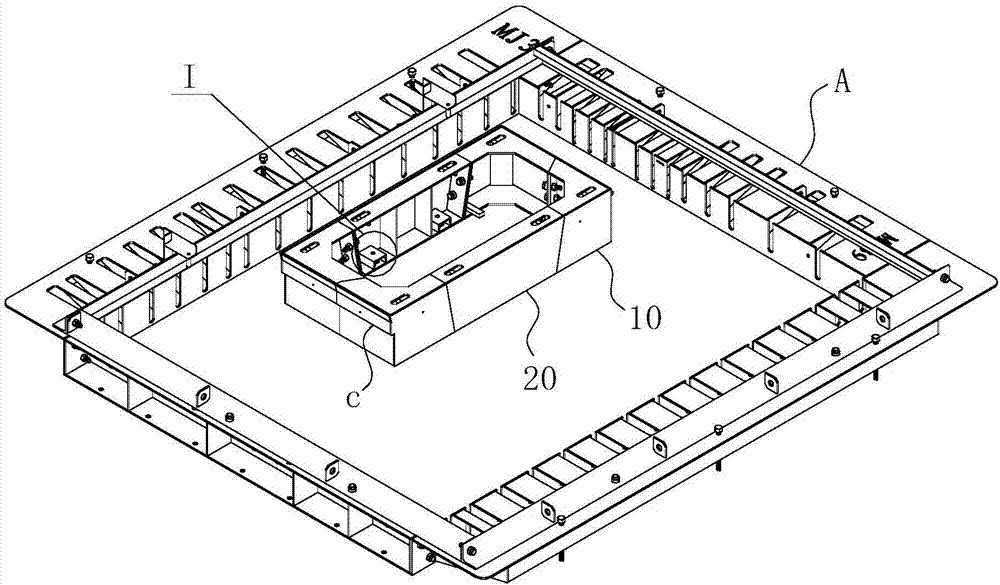

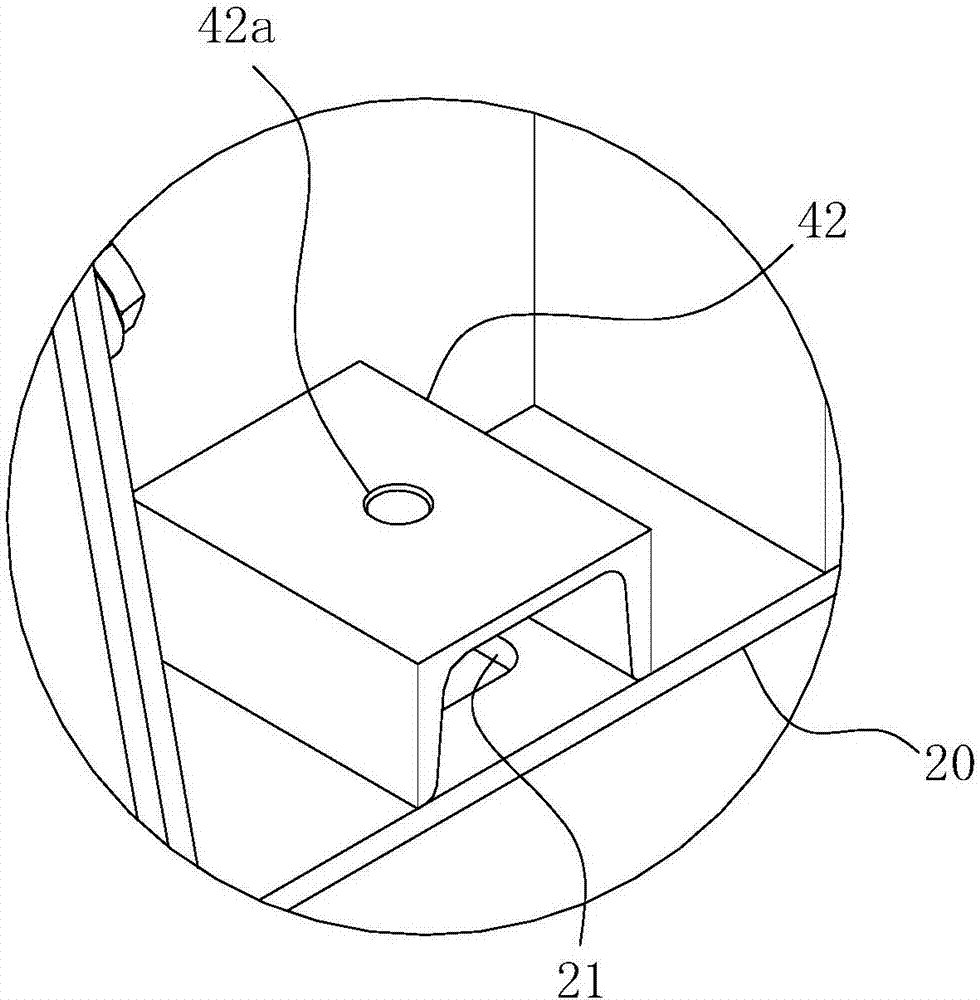

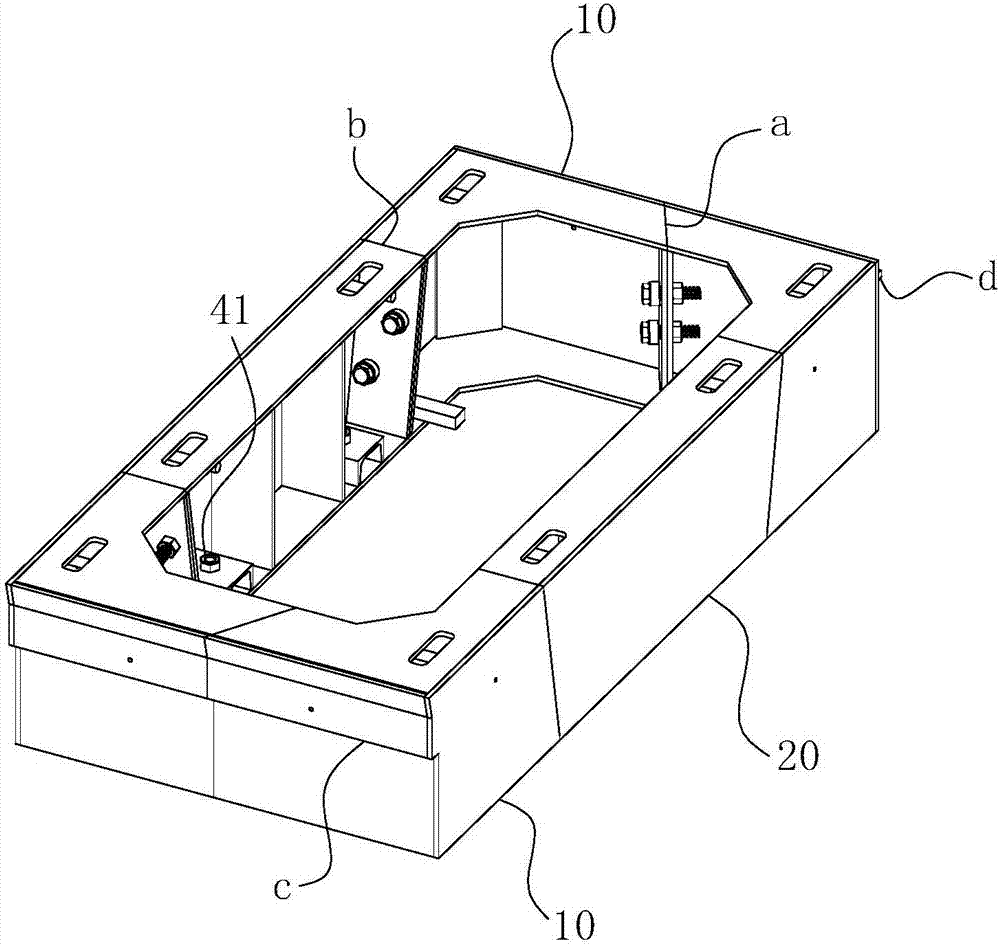

[0030] The specific structure of the present invention refers to Figure 1-6 As shown, it includes a mold body for placement in the mold cavity of wall panel mold A. When in use, the mold body is the same as the wallboard mold A, and is placed horizontally on a certain mold surface, which is referred to as "base surface" here. The aforementioned “vertical direction” corresponds to the direction perpendicular to the base plane. When the mold body and wallboard mold A are as a whole figure 1 When shown on the base surface, the space between the mold body and the wallboard mold A has just formed a "back"-shaped groove-like pouring area for cement pouring. After laying steel bars, pouring cement and even waiting for the cement to harden in the pouring area, remove the mold body and wallboard mold A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com