Device of fuel injection system and metal-to-metal sealing connection arrangement

A technology for connecting components and metal seals, which is applied in the direction of fuel injection devices, special fuel injection devices, mechanical equipment, etc., can solve the problems of pre-tightening force not being determined to a large extent, large deviation of sealing position, and large safety factor, etc., to achieve The effect of reducing material usage, improving sealing effect, and increasing power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

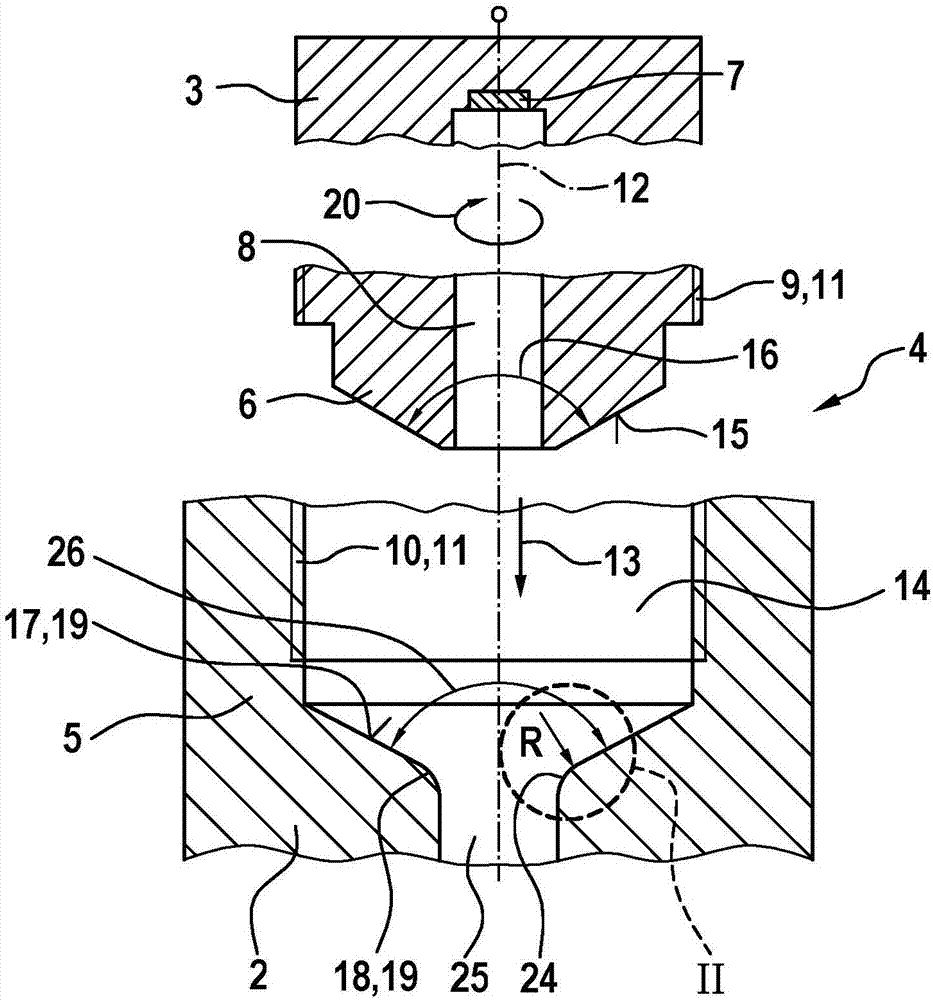

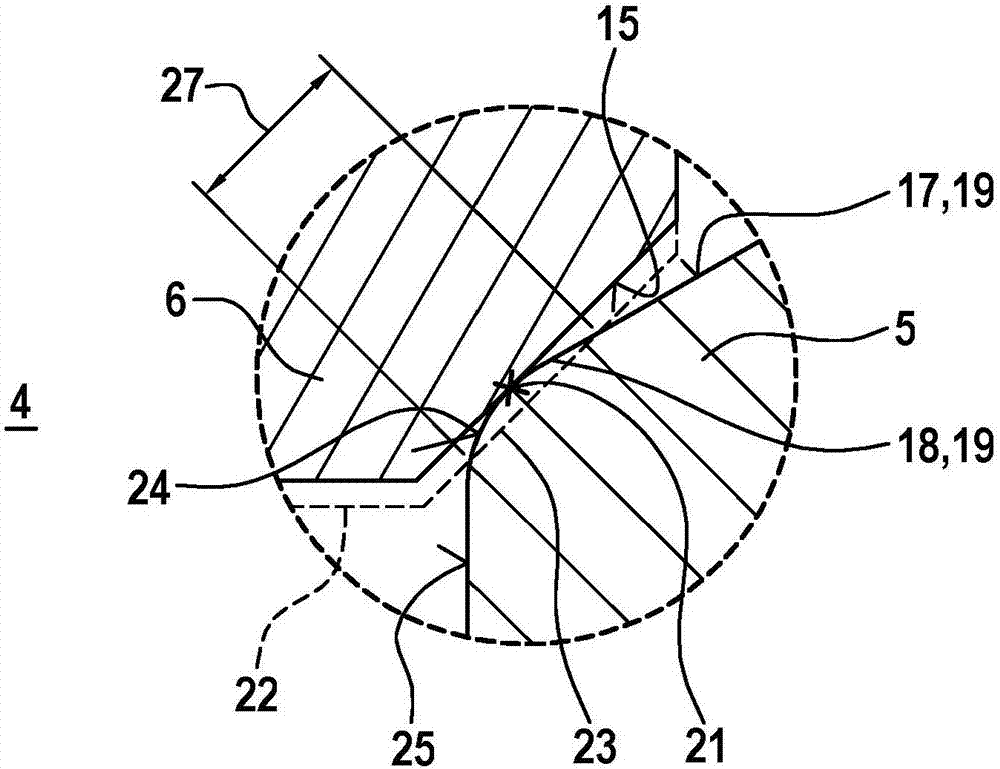

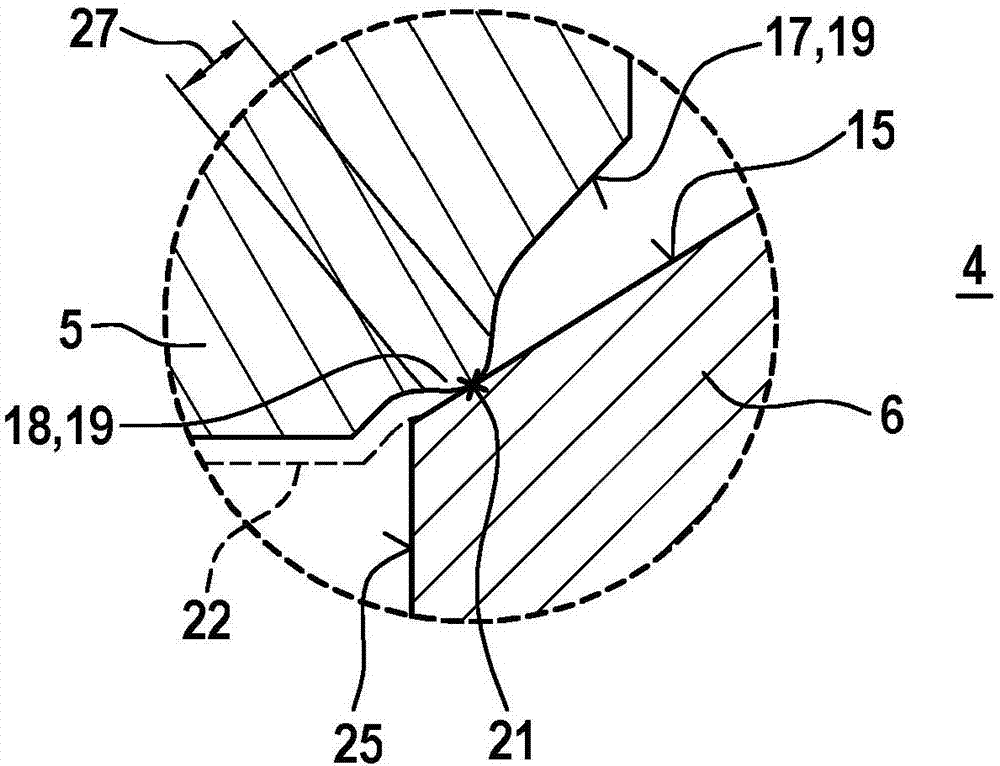

[0022] figure 1 shows a device 1 of a fuel injection system with a fuel-conducting part 2 and a connection part 3 , wherein the connection assembly 4 can be built on a connection partner 5 arranged on the part 2 and a connection partner arranged on the connection part 3 between 6. here, figure 1 In a simplified schematic sectional view corresponding to the first exemplary embodiment, the connection assembly 4 is shown in the state before assembly, in which state the connection partner 6 on the connection part 3 serves as the first connection partner 6, and on the part 2 The upper connection partner 5 serves as the second connection partner 6 .

[0023] The component 2 can be designed in particular as a fuel distribution rail 2 . The connecting piece 3 can be designed as a sensor 3 . For this purpose, a sensor element 7 can be provided which, in the assembled state, measures the fuel pressure present, for example, in the axial bore 8 of the connecting part 3 . The connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com