Motor insulating framework with asymmetrical tooth parts, motor stator, motor and compressor

An insulating frame and asymmetrical technology, which is applied in the fields of motor stators, asymmetrical motor insulating frames for teeth, motors and compressors, can solve the problems of large wind-milling losses in airflow, and achieve reduced wind-milling losses, reduced pressure, and The effect of reducing drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

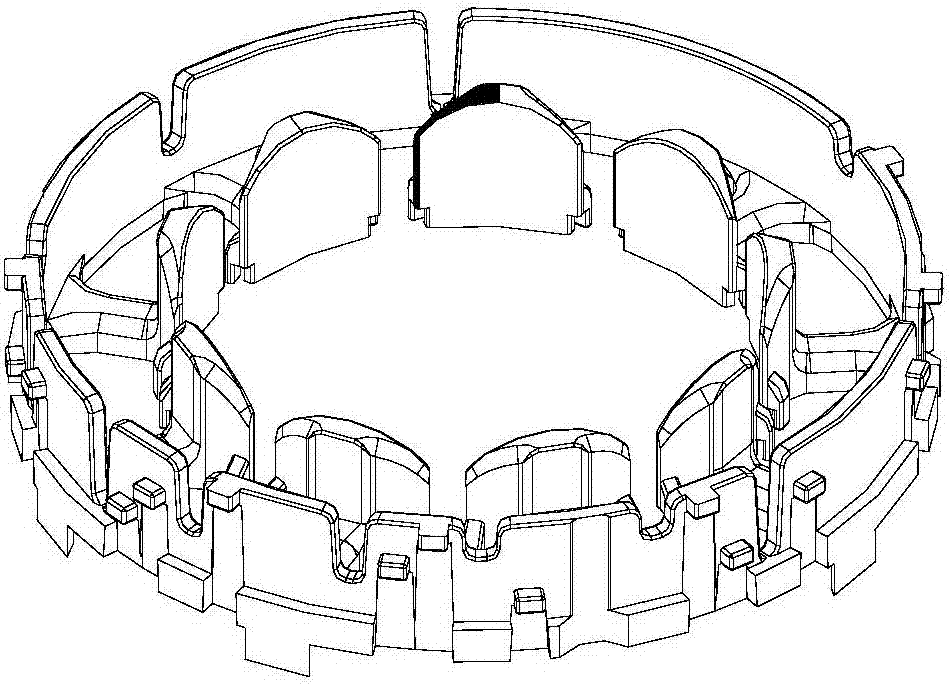

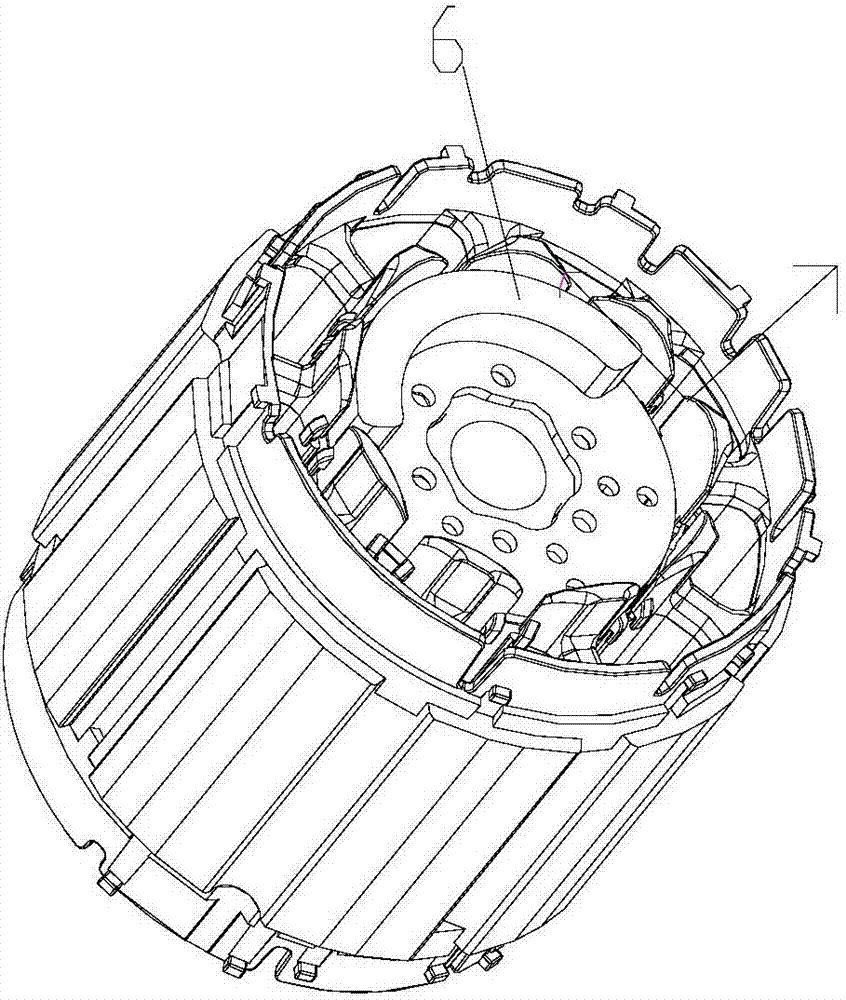

[0037] Such as Figure 4-6 As shown, the present invention provides an asymmetrical toothed motor insulation frame, which is characterized in that it includes:

[0038] An annular part 1; a plurality of dedendum parts 2 are arranged on the inner wall of the annular part 1 and protrude from the inner wall;

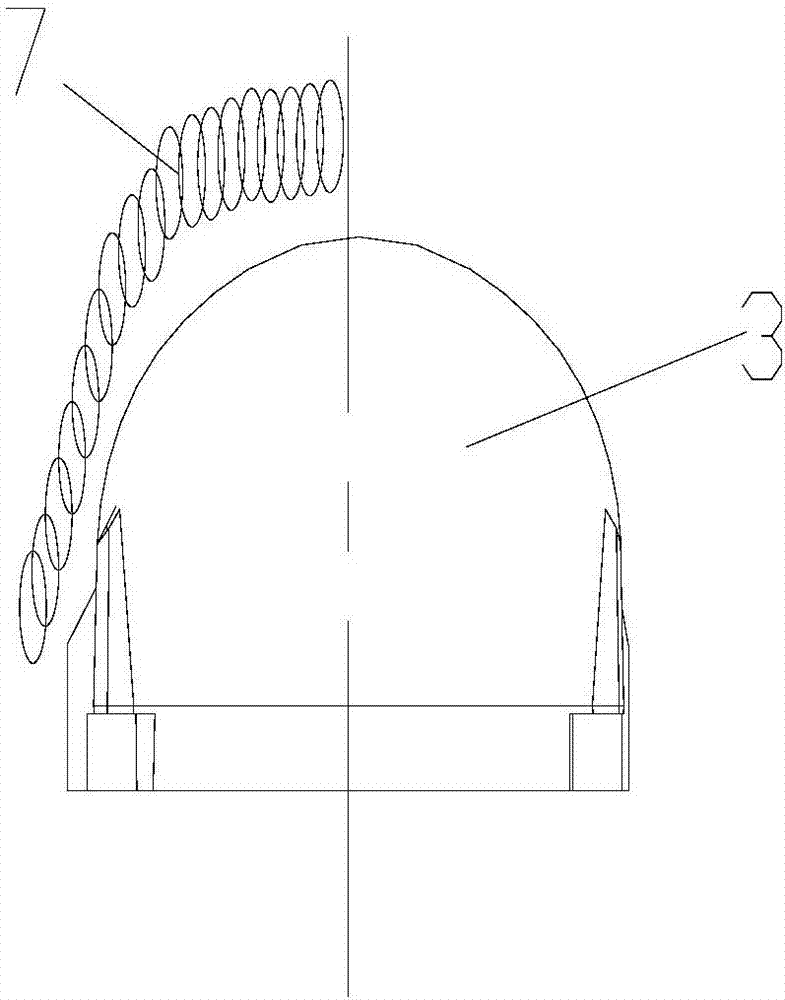

[0039] a tooth portion 3 connected to the free end of the dedendum portion 2,

[0040] The tooth portion 3 includes a bottom surface 31 and a top surface 32 oppositely arranged along the axial direction of the skeleton (that is, the axial direction of the annular portion), and a first side surface 33 and a second side surface 34 oppositely arranged along the circumferential direction of the skeleton. , the top surface 32 includes a top 35 with the highest axial height, a first transition surface 36 connected between the top 35 and the first side 33, and a transition surface 36 connected between the top 35 and the second side. The second transition surface 37 between the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com