Multi-angle testing device and operation method thereof

A test device, multi-angle technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of cumbersome steps and achieve the effect of accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

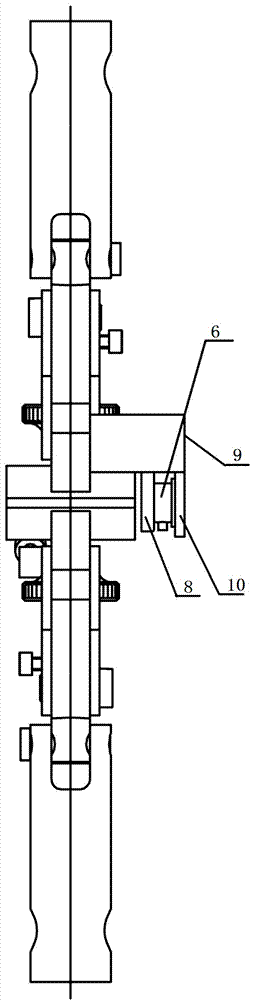

[0021] Embodiment 1: A kind of multi-angle testing device, comprises first fixed ring 1 and second fixed ring 2; Both are arc-shaped, set opposite to each other, and are provided with waist-shaped groove along the middle part of arc; First fixture 3 and One end of the second fixture 4 is provided with a roller 11, the roller is located in the waist groove, the fixture next to the roller is provided with a locking mechanism, and the other end is used to compress the test piece to be tested, the first fixture 3 and the second A rod driver 5 is connected between a fixed ring 1, and an angle sensor 6 is installed between the second clamp 4 and the second fixed ring 2; the arc outside of the first fixed ring 1 and the second fixed ring 2 is also Connecting columns 7 are respectively connected.

[0022] Further, the central angle corresponding to the waist-shaped grooves in the first fixing ring 1 and the second fixing ring 2 is 90 degrees.

[0023] Further, one end of the first cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com