Oil well pressure recovery testing device and system

A technology for restoring test and pressure, applied in the direction of measuring devices, instruments, etc., can solve the problems of cumbersome operation, polluted well site, and bulky equipment, etc., to achieve the effect of increasing the air intake area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

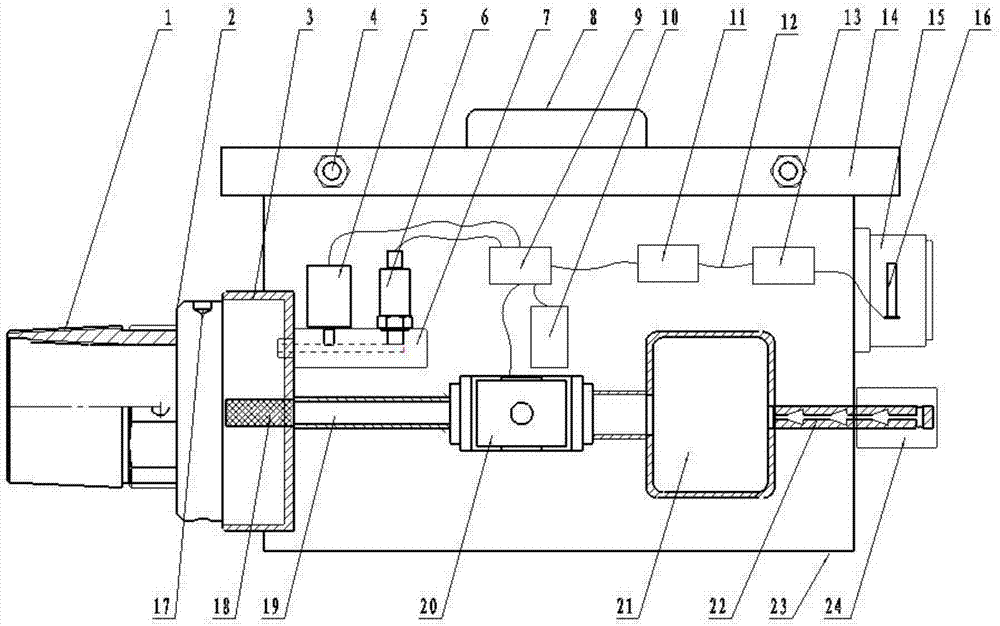

[0028] Such as figure 1 As shown, the oil well pressure recovery testing device of the present embodiment includes a box body 23, a box cover 14 and an oil-gas cavity 3 pierced on the side wall of the box body 23. The box cover 14 is provided with a handle 8, and the box cover 14 passes through the The plum blossom anti-theft screw 4 is installed on the box body 23, and the box body 23 is provided with a deflation unit and a control unit;

[0029]The deflation unit includes an airway pipeline 19 , a deflation solenoid valve 20 , a buffer tank 21 and an exhaust muffler 22 connected in sequence. Wherein the airway pipeline 19 communicates with the oil-gas chamber 3, and a barrel-type, 150-mesh filter 18 is buckled at the connection between the oil-gas chamber 3 and the airway pipeline 19. The filter screen 18 is located in the oil-gas chamber 3 and is different from the airway pipeline 19. One side of the filter screen 18 is sprayed with an anti-corrosion coating to enhance the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com