Temporary plugging turnaround fracture method

A technology of temporary plugging agent and working fluid, which is applied in chemical instruments and methods, earthwork drilling, and fluid production, etc., to achieve the effects of less damage, simple delivery operation, and high plugging rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

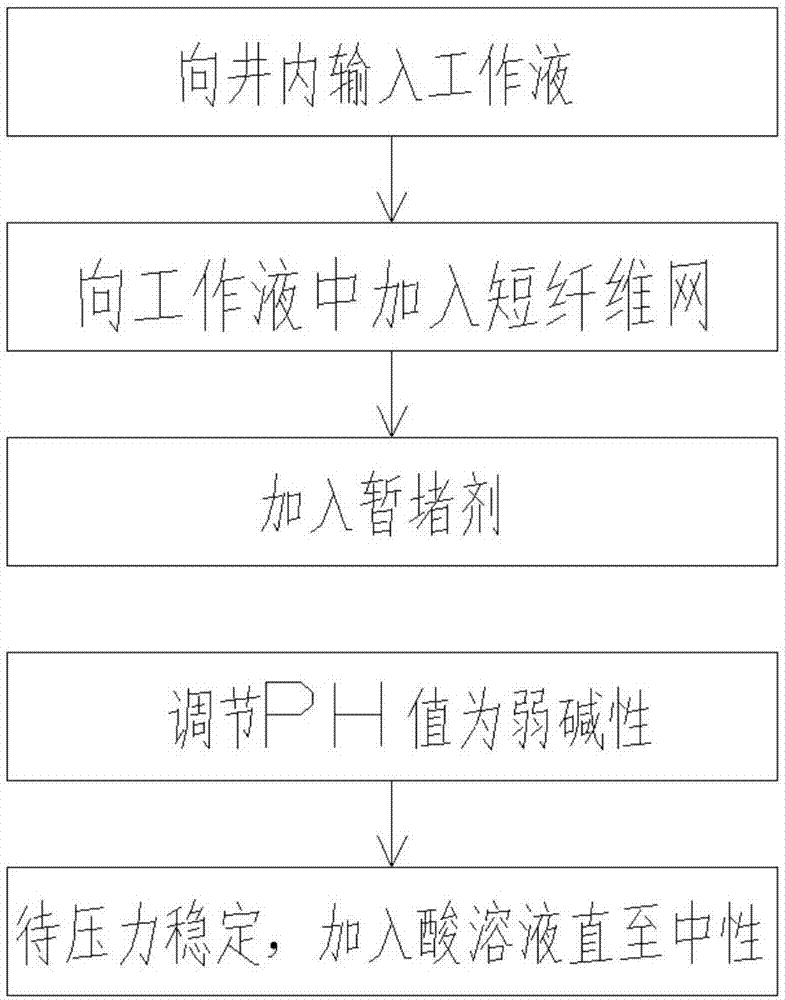

[0046] The invention provides a temporary plugging diversion fracturing method. By pumping a high-strength water-soluble (oil-soluble) temporary plugging agent into the formation, the previous fractures are blocked, the fluid is forced to divert, and new fractures are opened to complicate the fracture morphology, thereby increasing single well production and controlling reserves. During the construction process, large particle temporary plugging agent is added to the formation in a timely manner, and the fluid follows the principle of flowing in the direction of least resistance. The temporary plugging agent seals the original fracture and produces a high-strength filter cake near the wellbore. Subsequent working fluid cannot continue to flow into the original fracture, forcing the fracturing fluid to open a new fracture at a relatively weak point in the original fracture. In the stress contour area, the new cracks continue to extend along the crack initiation direction, and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com