Regeneration treatment method and device for carbon fiber reinforced composite

A technology for reinforced composite materials and treatment methods, which is applied in the field of carbon fiber reinforced composite material regeneration treatment and devices, can solve the problems of carbon fiber precursors such as reduced strength, non-recyclable use, and unfriendly environment, so as to save regeneration costs and adjust temperature Controlled, temperature controllable heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

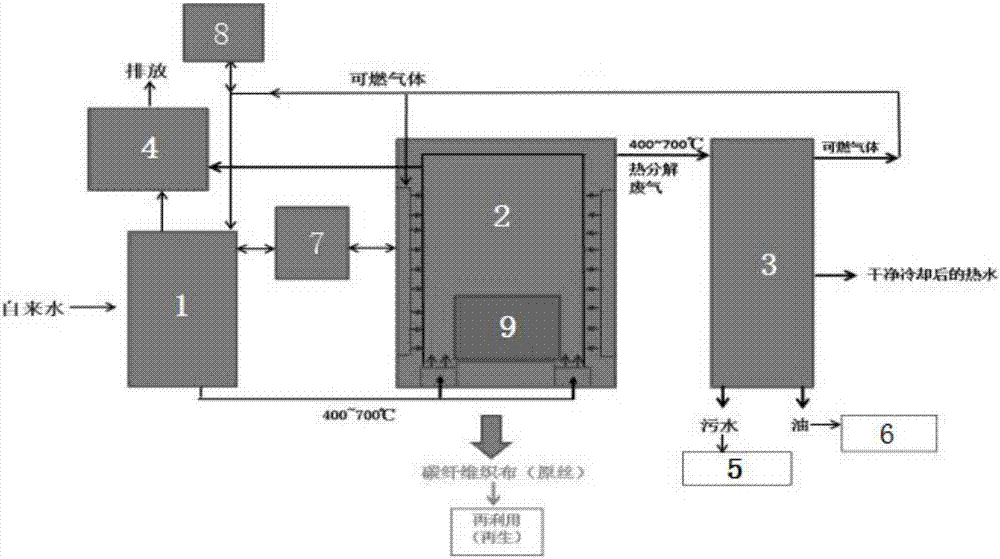

[0027] The closed-loop equipment system of the present invention is as figure 1 As shown, it includes a superheated steam generator 1, a treatment furnace 2, an oil-water-gas separation device 3, a harmful gas treatment device 4, a sewage treatment device 5, an oil treatment device 6, and a temperature control system 7; the superheated steam generator 1, the treatment The furnace 2 and the oil-water-gas separation device 3 are connected successively, the sewage outlet of the oil-water-gas separation device 3 is connected with the sewage treatment device 5, the oil outlet of the oil-water-gas separation device 3 is connected with the oil treatment device 6, and the oil treatment device The combustible gas outlets of 3 are respectively connected with the superheated steam generator 1 and the treatment furnace 2, and the temperature control system 7 is connected with the superheated steam generator 1 and the treatment furnace 2 respectively, and the combustion gas in the superheat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com