A vacuum induction melting furnace for copper alloy

A vacuum induction smelting and copper alloy technology, which is applied in the direction of furnace, furnace components, charge manipulation, etc., can solve the problems that affect the copper purity and is not suitable for large-scale industrial production, and achieve short vacuuming time, high feeding effect, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

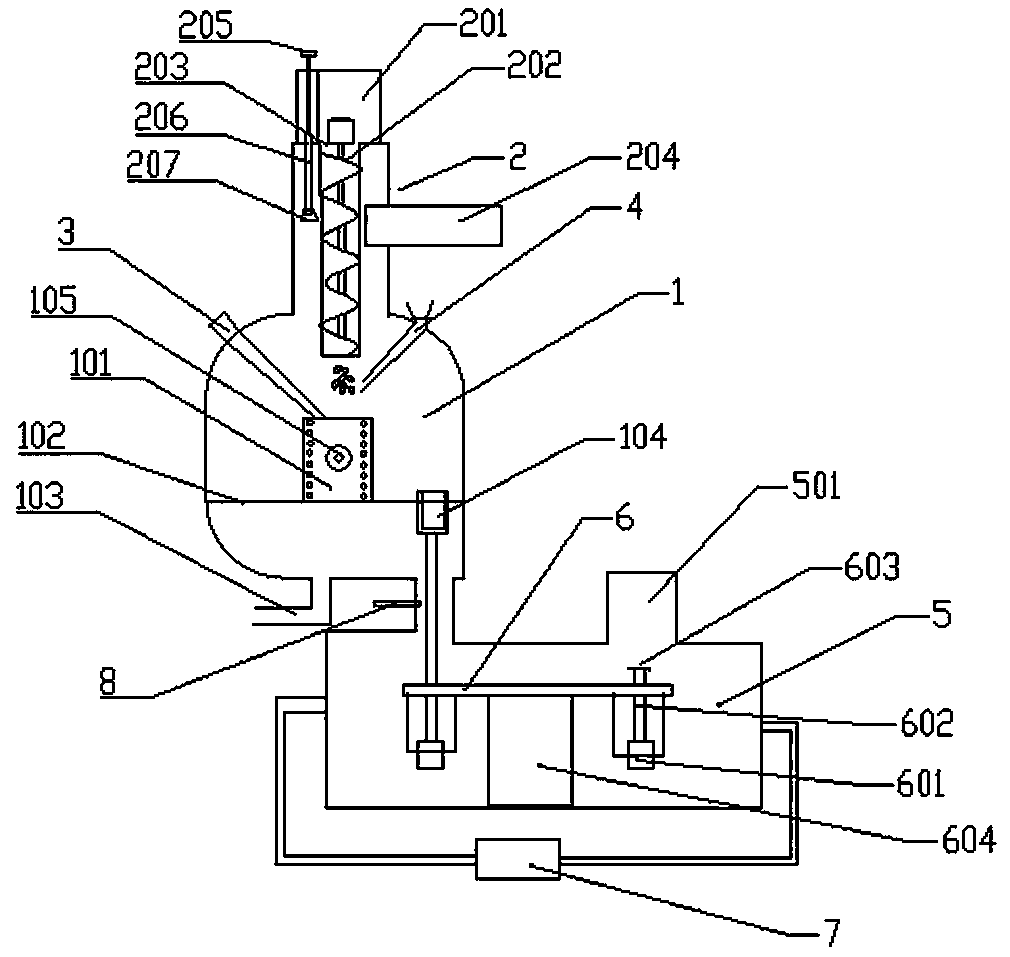

[0021] Specific embodiment 1: as figure 1 As shown, this embodiment discloses a vacuum induction melting furnace for copper alloys, including:

[0022] Furnace body 1, the furnace body is provided with a bracket 102, the induction furnace is located on the bracket (102), the two sides of the induction furnace are connected with a rotating rod (105), the rotating rod is connected to the inner wall of the furnace body, and can rotate relative to the furnace body , the rotating rod is driven to rotate by the rotating structure.

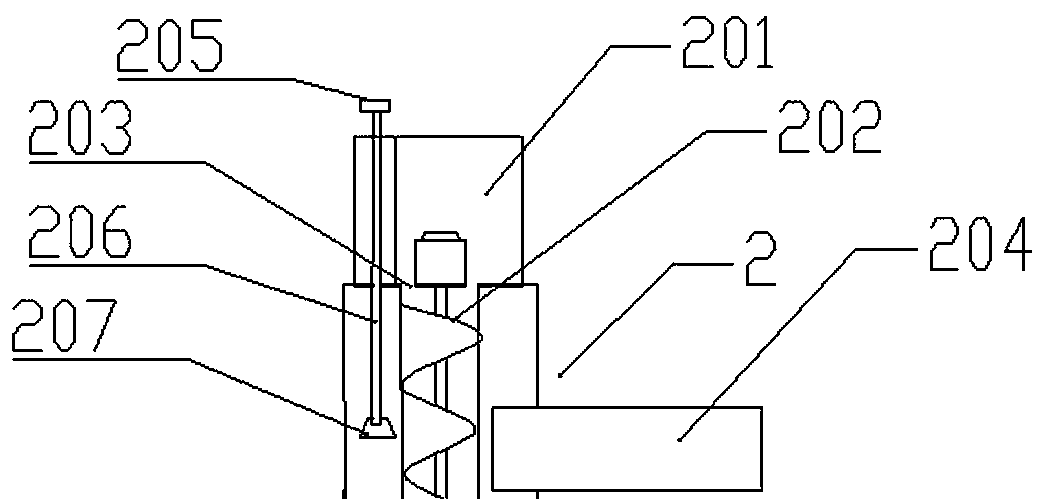

[0023] Feeding device 2, the feeding device is used to add copper material to the inside of the furnace body, the feeding device is located at the feeding port on the upper end of the furnace body, and the feeding device includes a material cavity 201 and a first screw for conveying copper material connected to the material cavity Rod 202, the inside of the material chamber is provided with a first motor connected to the first screw rod, the first motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com