A kind of microbial fast fermented feed and preparation method thereof

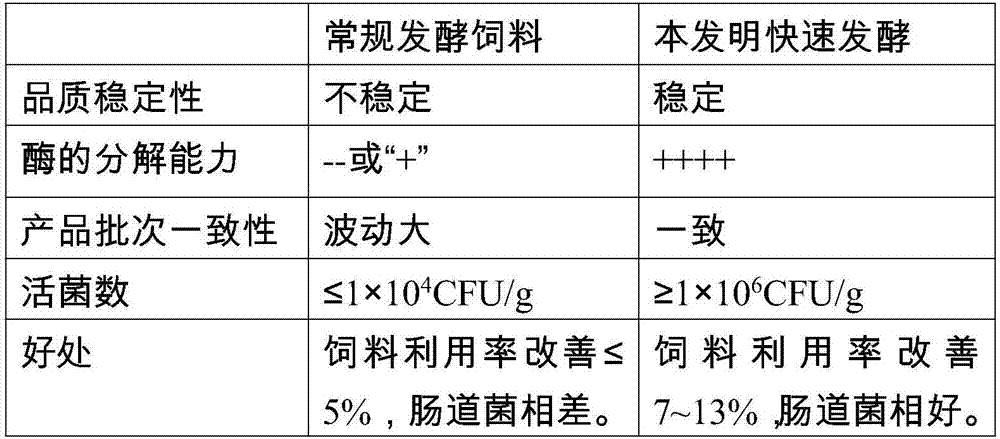

A technology for fermenting feed and microorganisms, which is applied to the field of microbial rapid fermentation feed and its preparation, can solve the problems of inability to ferment feed production, limit feed fermentation production, unstable product quality, etc., and achieve large-scale production, high production efficiency, and economical efficiency. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

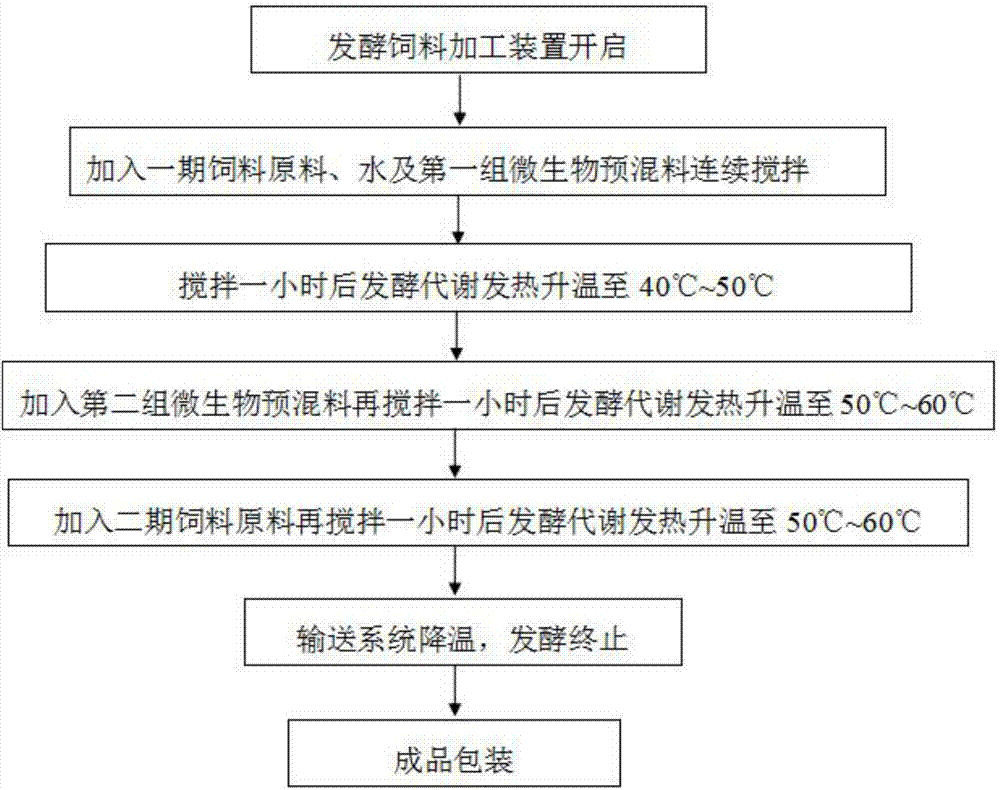

Method used

Image

Examples

Embodiment 1

[0038] Propagate Bacillus subtilis and Bacillus coagulans in a liquid medium at a ratio of 1:1, and the formula of the medium is as follows: casein peptone 5-10%, salt 0.5-0.8%, sucrose 2.8-3.5%, hydrochloric acid 0.1- 0.5%, water 80-90%. After culturing at 37° C. for 12 hours, the culture liquid containing Bacillus subtilis and Bacillus coagulans was obtained by performing secondary fermentation on the bacterial liquid obtained from the primary fermentation for 24 hours. The above-mentioned culture solution was sprayed into auxiliary materials containing 10% soybean hull powder and 90% diatomaceous earth, and dried at a low temperature of 35° C. for 50 minutes to obtain a microbial premix. The total concentration of Bacillus subtilis and Bacillus coagulans in the auxiliary material in the prepared microbial premix is 1*10 8 CFU / g.

[0039] The feed raw material is fermented in a feed fermentation mixer by using the microbial premix to prepare the fermented feed. The spec...

Embodiment 2

[0042] Propagate and cultivate Bacillus subtilis, Bacillus coagulans and yeast at a ratio of 1:1:1, spray the bacterial solution into the auxiliary material mixed with 15% soybean hull powder and 85% diatomaceous earth, and dry at 37°C for 45 minutes , prepared into the first microbial premix. The total concentration of Bacillus subtilis, Bacillus coagulans and yeast in the auxiliary material in the prepared first microbial premix is 1*10 9 CFU / g.

[0043] Propagate and cultivate Bacillus subtilis, Bacillus coagulans and yeast at a ratio of 1:3:1, spray the bacterial solution into the auxiliary material mixed with 15% soybean hull powder and 85% diatomaceous earth, and dry at 37°C for 45 minutes , prepared into the second microbial premix. The total concentration of Bacillus subtilis, Bacillus coagulans and yeast in the auxiliary material in the prepared first microbial premix is 1*10 9 CFU / g.

[0044] The feed raw material is fermented in a feed fermentation mixer by ...

Embodiment 3

[0047] Propagate and cultivate Bacillus subtilis, Bacillus coagulans and yeast at a ratio of 1:3:1, spray the bacterial solution into the auxiliary material mixed with 10% soybean hull powder and 90% diatomaceous earth, and dry at 33°C for 55 minutes , prepared into the first microbial premix. The total concentration of Bacillus subtilis, Bacillus coagulans and yeast in the auxiliary material in the prepared first microbial premix is 1*10 10 CFU / g.

[0048] Propagate and cultivate Bacillus subtilis, Bacillus coagulans and yeast at a ratio of 1:1:1, spray the bacterial liquid into the auxiliary material mixed with 10% soybean hull powder and 90% diatomaceous earth, and dry at 33°C for 55min at low temperature , prepared into the second microbial premix. The total concentration of Bacillus subtilis, Bacillus coagulans and yeast in the auxiliary material in the prepared second microbial premix is 1*10 10 CFU / g.

[0049] The feed raw material is fermented in a feed ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com