Slag removal device for drilling

A technology of slag removal and power device, which is applied in the direction of earthwork drilling, wellbore/well components, etc., can solve the problems of slag removal equipment affecting drilling efficiency, etc., and achieve the effects of saving operation time, improving operation efficiency and reducing operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

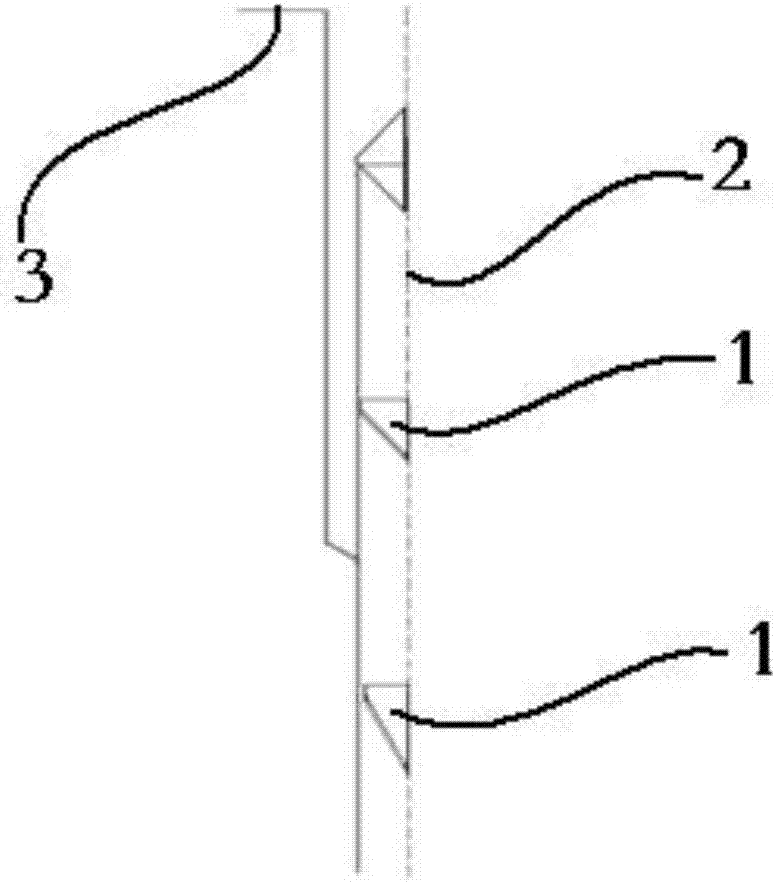

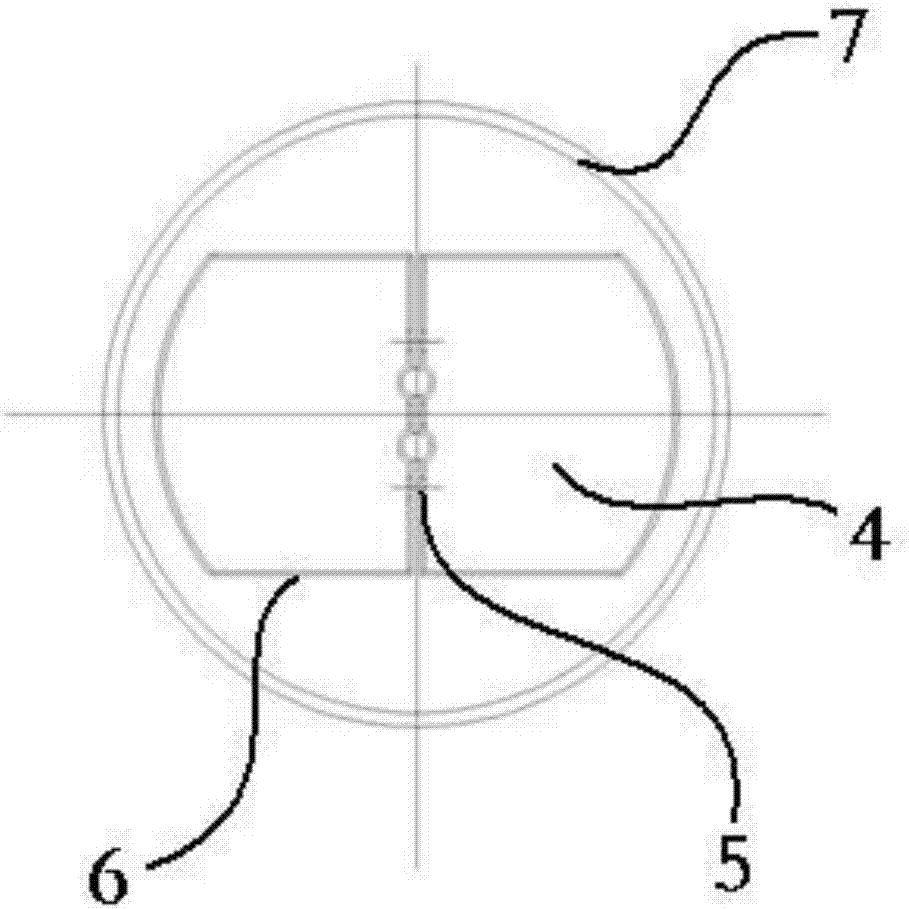

[0040] figure 1 It is a partial structural schematic diagram of a slag removal device for drilling provided in Embodiment 1 of the present invention; figure 2 for figure 1 The top view of the upper-level material lifting mechanism shown; Figure 1-2 As shown, the slag removal device for drilling provided in this embodiment includes a steel cable 2 suitable for connecting an impact hammer at one end, and a wellhead power device connected to the other end of the steel cable 2. The wellhead power device can drive the steel cable 2 to lift or The reciprocating movement of lowering, and several lifting mechanisms 1 arranged on the steel cable 2, several lifting mechanisms 1 are fixedly arranged on the steel cable 2 at intervals from the top of the impact hammer to the wellhead 3, and the lifting mechanism 1 is bucket-shaped The structure includes two sets of side plates 6 arranged in parallel on both sides of the steel cable 2, and a connecting plate arranged between each set of...

Embodiment 2

[0051] As an alternative to the first embodiment, this embodiment provides a slag removal device for drilling. The difference between the lifting mechanism (1) of the slag removal device and the first embodiment is that:

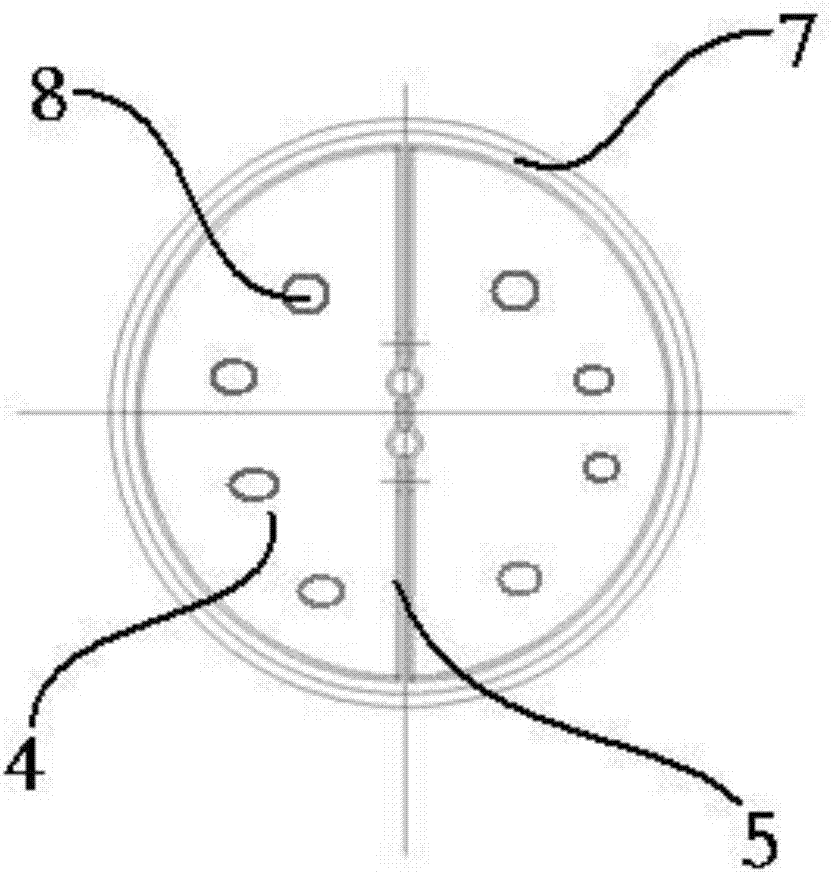

[0052] Such as image 3 As shown, the housing of the lifting mechanism is a bucket-shaped structure with a circular outer contour adapted to the inner contour of the well wall (7), and the cross-section of the second opening at the bottom of the housing is equivalent to the well hole The two D-shaped material receiving plates (4) symmetrically arranged at the second opening can close the entire well hole, and a number of hollow holes (8) are formed on the material receiving plate (4) to form a discharge channel for the reciprocating flow of mud, which can Reducing the resistance suffered by the material lifting mechanism when lifting or falling can also reduce the impact force on the butt joint material plate (4), and avoid damage and fracture of the joint b...

Embodiment 3

[0056] This embodiment, as an alternative to the first embodiment, provides a slag removal device for drilling. The difference between the lifting mechanism of the slag removal device and the first embodiment is that:

[0057] The material lifting mechanism is a shell with a top opening, and several hollow structures are formed on the bottom surface of the shell. Several material lifting mechanisms are fixedly arranged on the steel cable from the top of the impact hammer to the wellhead at intervals, so that from the top of the impact hammer to the wellhead The wellhead forms a continuous mud lifting channel, and a lifting mechanism first introduces the mud from the hollow structure into the shell during the falling process during a lifting cycle, and then rises to lift the mud inside; the lifting mechanism In the next lifting cycle, the upper-level lifting mechanism catches the mud raised by the lifting mechanism and starts to rise. In this way, the mud with high suspension co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com