Automatic calibration system and method for X-ray grating-based phase-contrast imaging

A technology of phase contrast imaging and automatic calibration, which is applied in material analysis using radiation, material analysis using wave/particle radiation, measuring devices, etc. It can solve problems such as affecting experimental efficiency and long adjustment time, and improve experimental efficiency. , The effect of reducing workload and reducing human eye errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

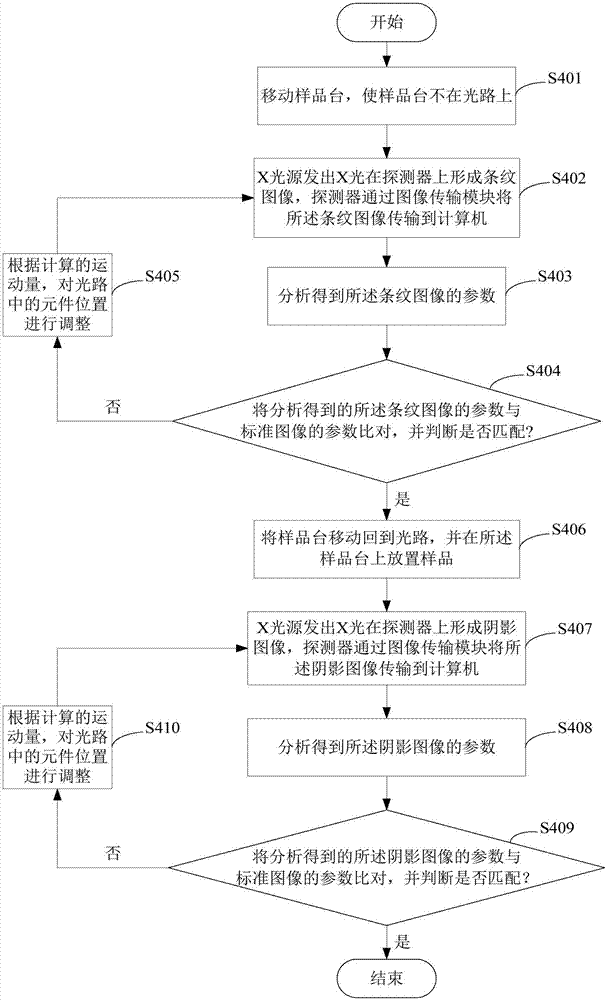

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

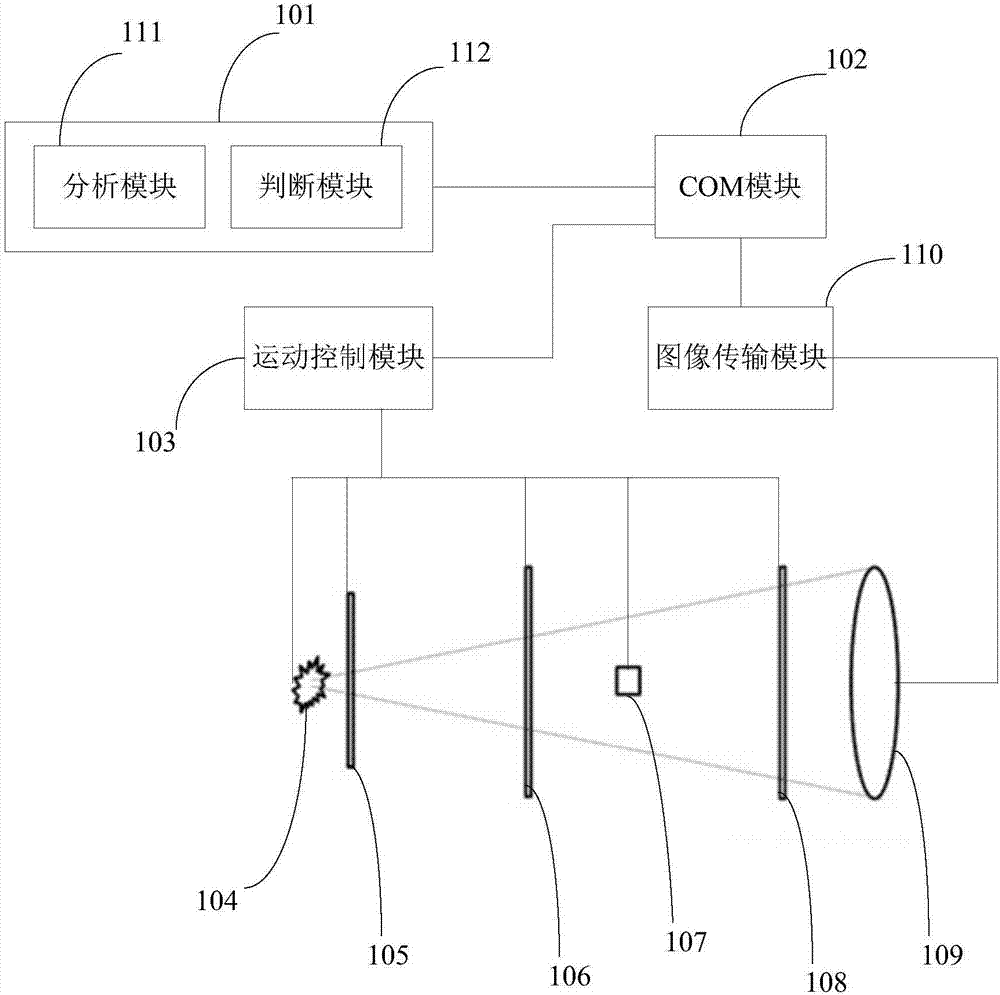

[0020] refer to figure 1 Shown is a hardware architecture diagram of the X-ray grating phase-contrast imaging automatic calibration system of the present invention.

[0021] The system includes a computer 101 , a COM module 102 , a motion control module 103 , an X light source 104 , a source grating 105 , a beam splitting grating 106 , a sample stage 107 , an analysis grating 108 , a detector 109 and an image transmission module 110 . Wherein: X light source 104, source grating 105, beam splitting grating 106, sample stage 107, analysis grating 108 and detector 109 are located in the center of the same optical path, COM module 102 is electrically connected with computer 101, motion control module 103, image transmission module 110 respectively Connection; the motion control module 103 is electrically connected to the X light source 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com