Vertical shaft non-suspension segmented stepping descending type integral metal formwork

A technology of metal formwork and formwork, which is applied in wellbore lining, underground chambers, shaft equipment, etc. It can solve problems such as poor effect, slurry leakage in the net size of the wellbore, and influence on the thickness of the wellbore wall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is a specific example of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

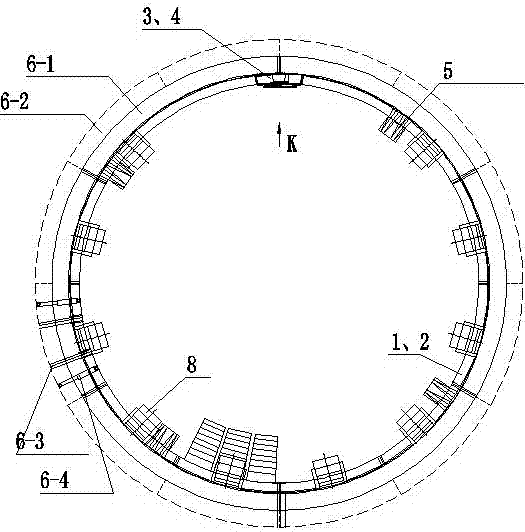

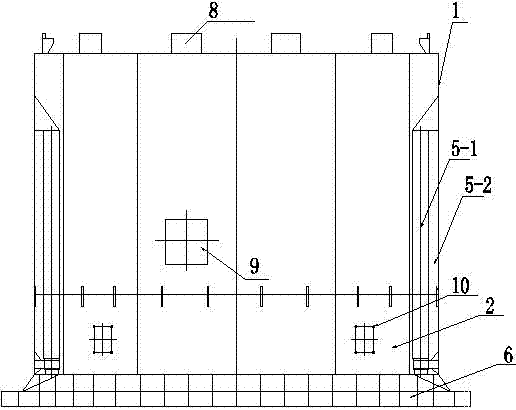

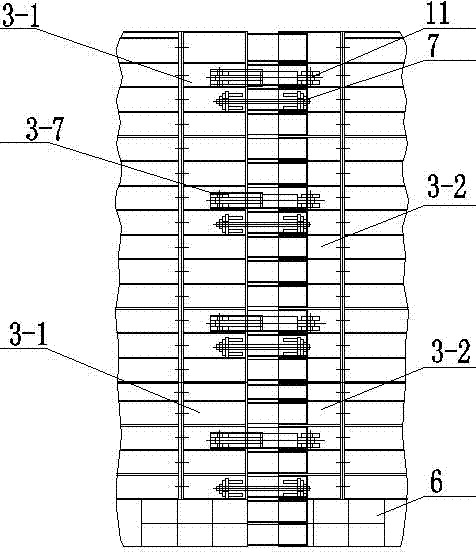

[0022] Such as figure 1 , figure 2 and image 3 As shown in the figure, there is a kind of step-down overall metal formwork without suspension in vertical shaft. The upper C-shaped formwork 1 and the lower C-shaped formwork 2 are both cylindrical with an opening. The upper C-shaped formwork 1 and the lower C-shaped formwork 2 The whole is rigidly connected by steel structure. The opening of the upper C-shaped formwork 1 is connected with an upper shrinkage opening closing module 3, and the opening of the lower C-shaped formwork 2 is connected with a lower shrinking opening closing module 4; The demoulding oil cylinder 11 that controls the shrinkage of the upper shrinkage port closing module 3 and the lower shrinkage port closing module 4 . The oil cylinder in the device can be controlled and provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com