Textile fabric and application thereof

A fabric and intermediate layer technology, applied in the direction of fabric, multi-strand fabric, textile, etc., can solve the problems of difficult control, unclear opening, low tear strength, etc., to reduce workload and cost, reduce workload and cost, the effect of improving air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

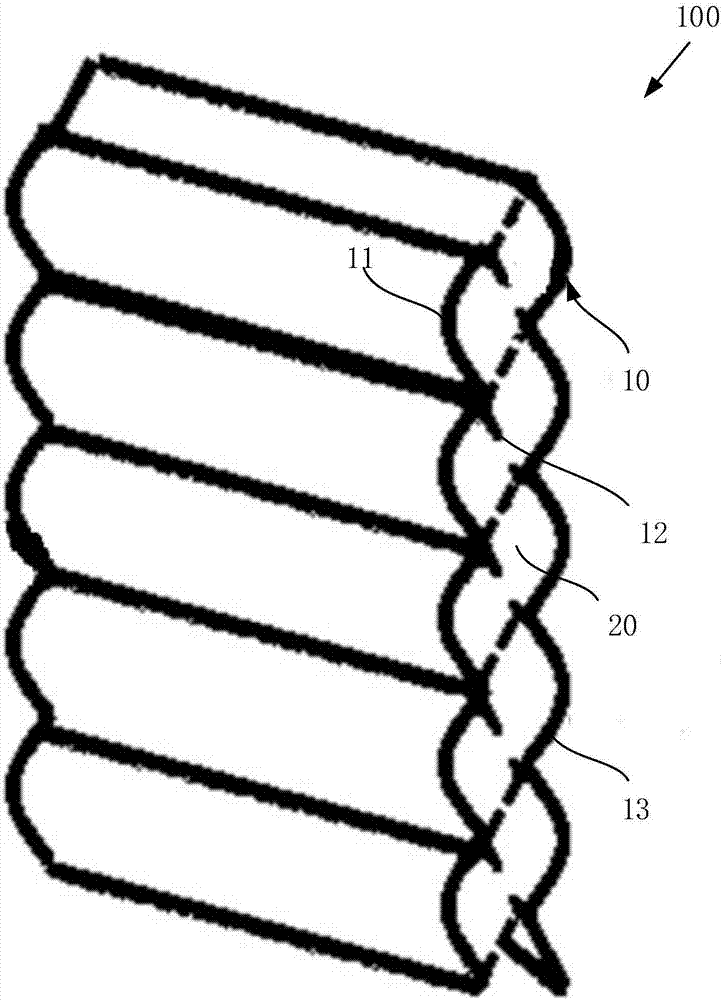

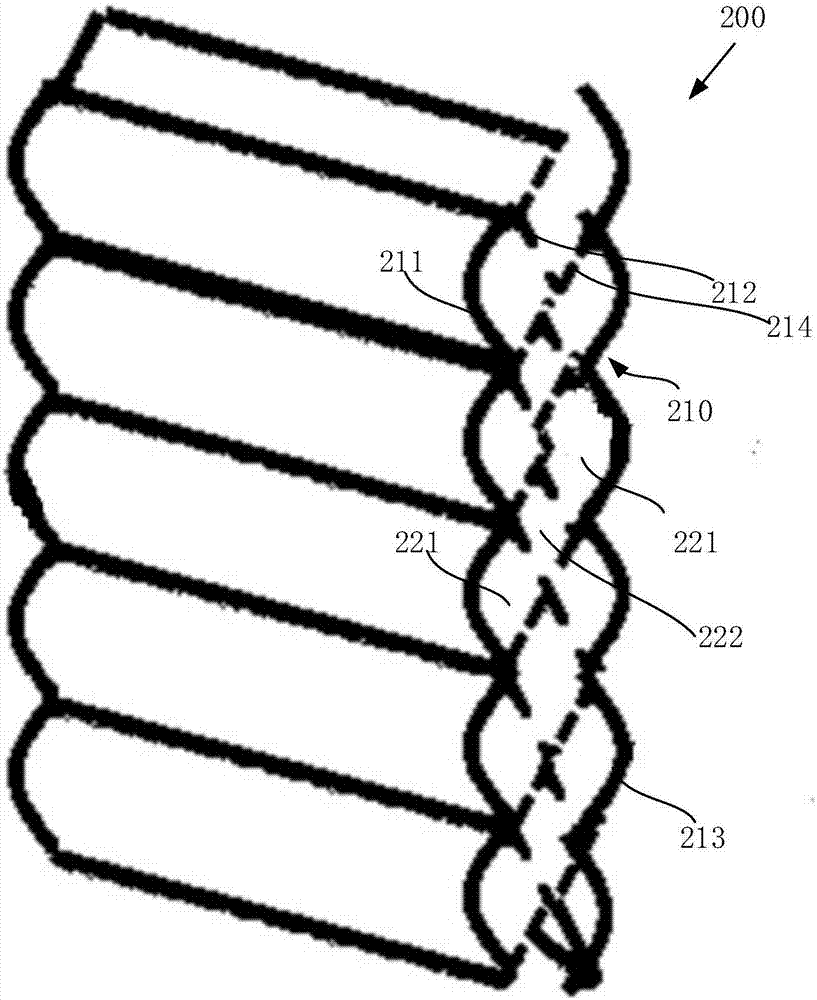

Method used

Image

Examples

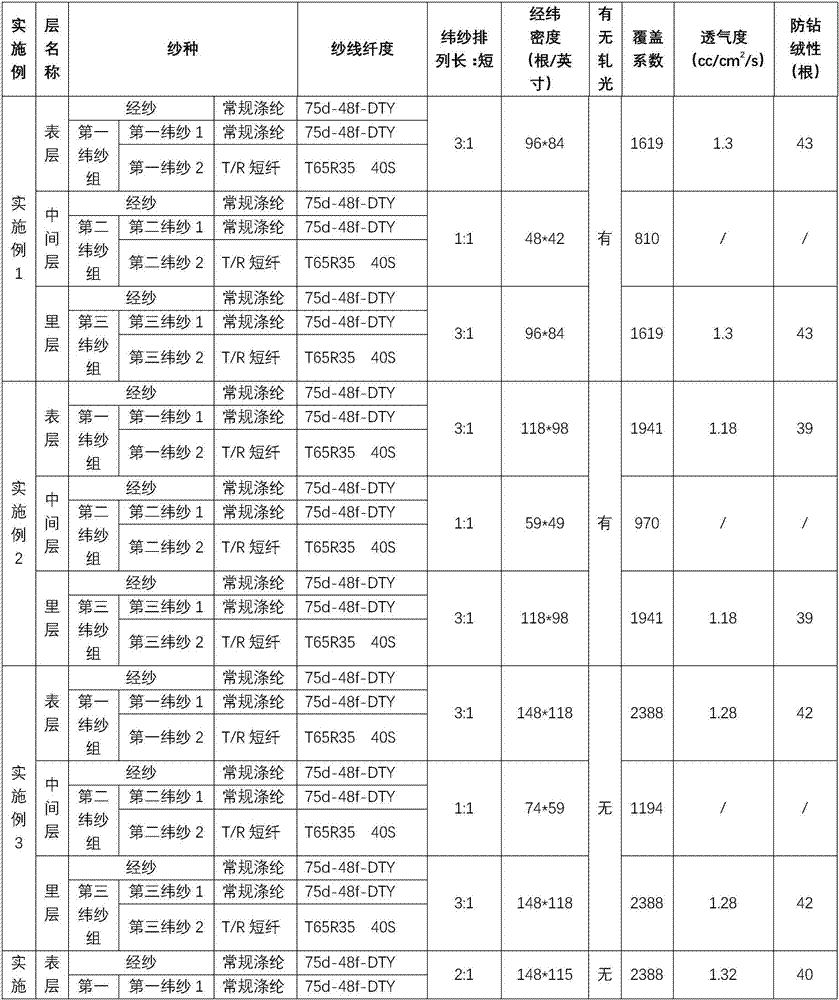

Embodiment 1

[0040] In the present embodiment, the step of weaving fabric is as follows:

[0041] Step 1, select warp material and weft material for textile:

[0042] Multiple warp yarns: a filament yarn whose material is 75d-48f-DTY conventional polyester yarn is selected,

[0043] Weft yarn group: including three sets of weft yarns, namely the first weft yarn group, the second weft yarn group and the third weft yarn group,

[0044] The first weft yarn group includes two kinds. The first weft yarn 1 is made of filament yarn of 75d-48f-DTY conventional polyester yarn, and the first weft yarn 2 is made of spun yarn of T65R35 40S T / R staple fiber, and the first weft yarn The arrangement of weft yarn 1 (filament yarn) and first weft yarn 2 (spun yarn) is 3:1,

[0045] The second weft yarn group includes two kinds, which are respectively the second weft yarn 1 and the second weft yarn 2. The material selected for the second weft yarn 1 is the same as that used for the first weft yarn 1, and ...

Embodiment 2

[0058] In the present embodiment, the step of weaving fabric is as follows:

[0059] Step 1, select warp material and weft material for textile:

[0060] Multiple warp yarns: a filament yarn whose material is 75d-48f-DTY conventional polyester yarn is selected,

[0061] Weft yarn group: including three sets of weft yarn groups, namely the first weft yarn group, the second weft yarn group and the third weft yarn group,

[0062] The first weft yarn group includes two kinds. The first weft yarn 1 is made of filament yarn of 75d-48f-DTY conventional polyester yarn, and the first weft yarn 2 is made of spun yarn of T65R35 40S T / R staple fiber, and the first weft yarn The arrangement of weft yarn 1 (filament yarn) and first weft yarn 2 (spun yarn) is 3:1,

[0063] The second weft yarn group includes two kinds, which are respectively the second weft yarn 1 and the second weft yarn 2. The material selected for the second weft yarn 1 is the same as that used for the first weft yarn 1...

Embodiment 3

[0071] In the present embodiment, the step of weaving fabric is as follows:

[0072] Step 1, select warp material and weft material for textile:

[0073] Multiple warp yarns: a filament yarn whose material is 75d-48f-DTY conventional polyester yarn is selected,

[0074] Weft yarn group: including three sets of weft yarns, namely the first weft yarn group, the second weft yarn group and the third weft yarn group,

[0075] The first weft yarn group includes two kinds. The first weft yarn 1 is made of filament yarn of 75d-48f-DTY conventional polyester yarn, and the first weft yarn 2 is made of spun yarn of T65R35 40S T / R staple fiber, and the first weft yarn The arrangement of weft yarn 1 (filament yarn) and first weft yarn 2 (spun yarn) is 3:1,

[0076] The second weft yarn group includes two kinds, which are respectively the second weft yarn 1 and the second weft yarn 2. The material selected for the second weft yarn 1 is the same as that used for the first weft yarn 1, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com