Lifting mechanism for taphole machine

A technology of a taphole machine and frame, which is applied in the field of the lifting mechanism for the taphole machine, which can solve the problems of time-consuming and labor-intensive on-site operations, and achieve the effect of large lifting force and precise control of the opening angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose, the specific embodiments, structural features and effects of the present invention are described in detail below with reference to the accompanying drawings and examples.

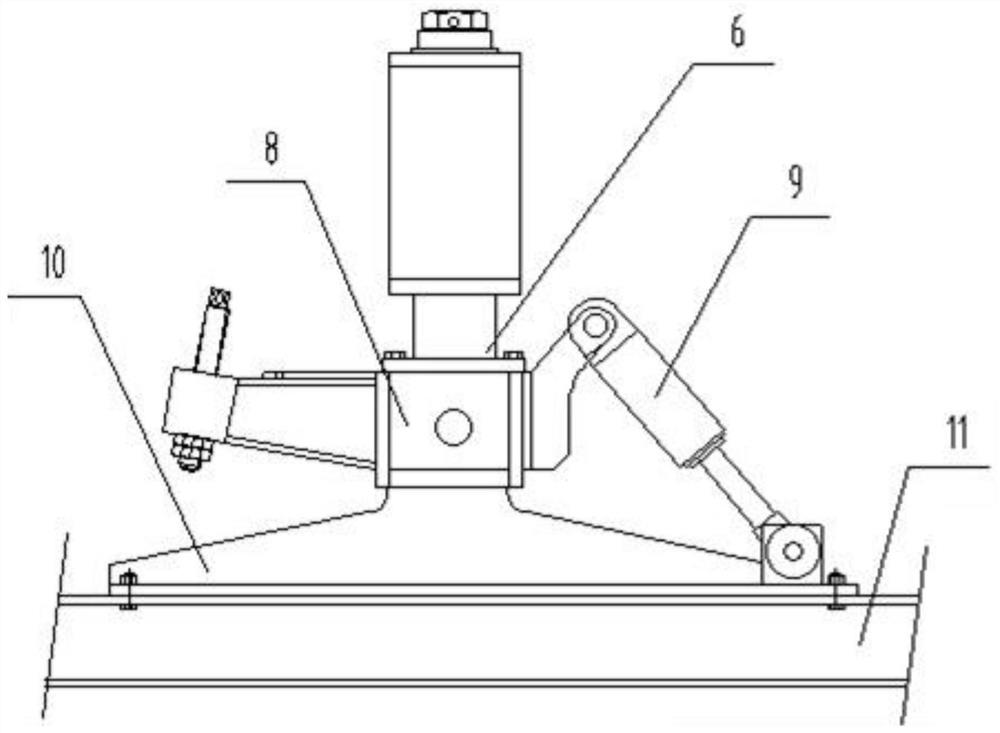

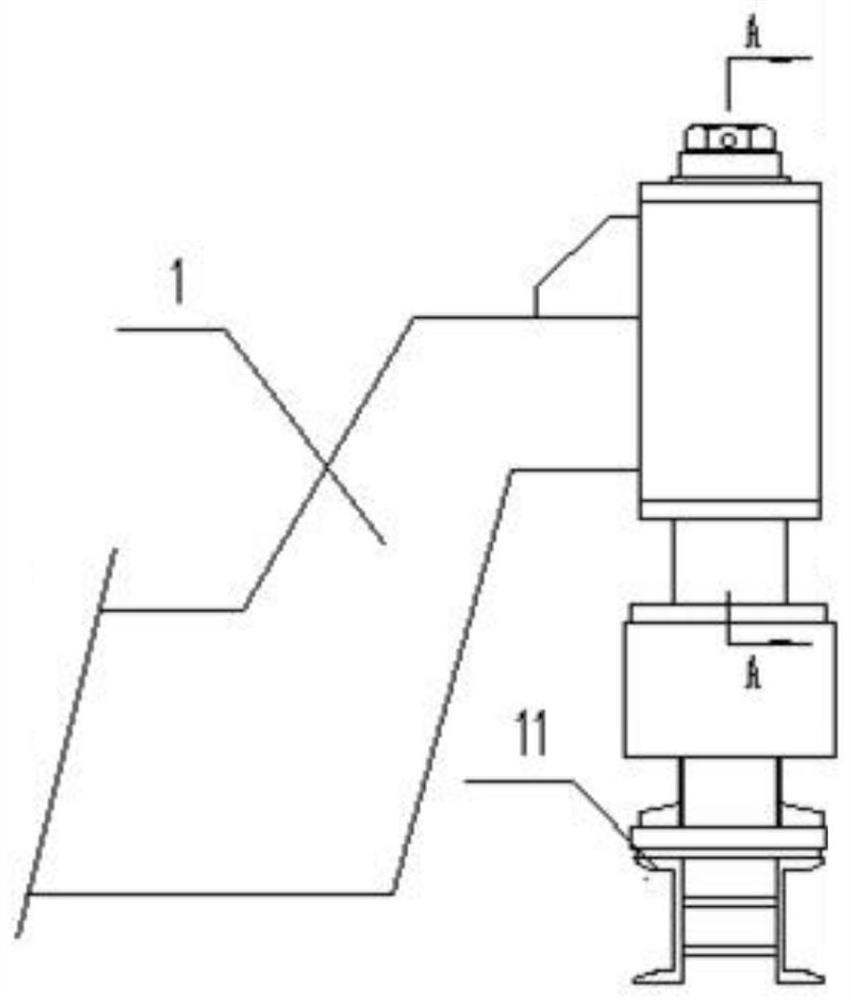

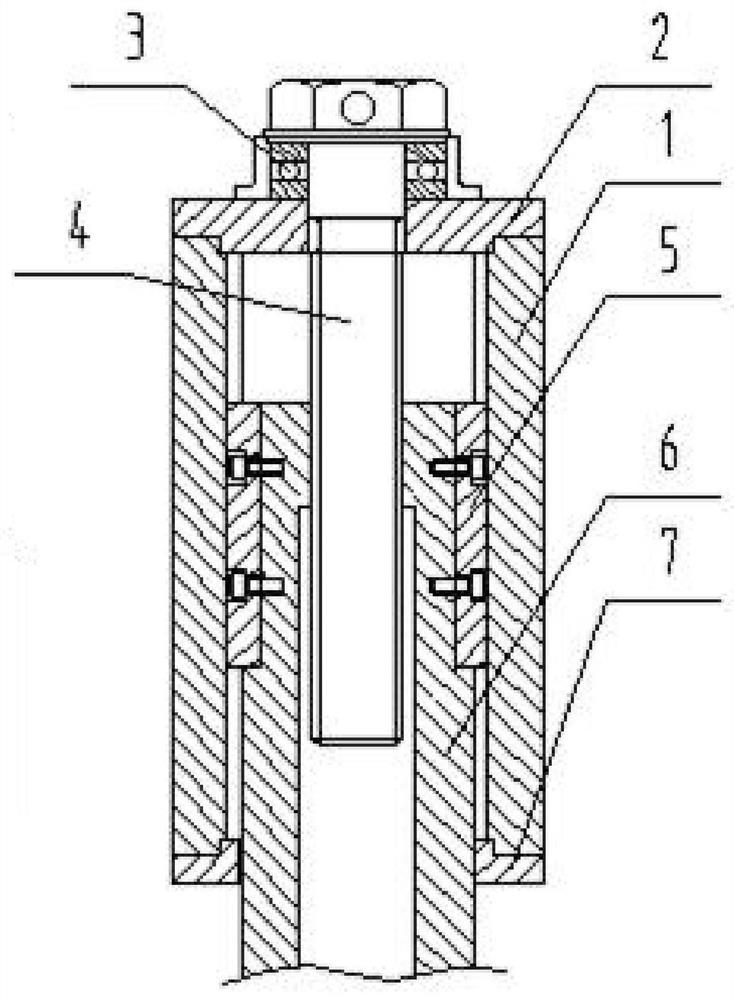

[0025] In order to solve the problem that when adjusting the working inclination of the taphole machine, the hanging frame is first disassembled, and then the closing hole position is re-adjusted to fix it, which leads to time-consuming and labor-intensive on-site operations. This embodiment provides a method such as Figure 1-Figure 3 The shown lifting mechanism for the taphole machine includes a hanging frame 8, and the hanging frame 8 is composed of a vertical plate, a horizontal plate connected to the upper end of the vertical plate, and also includes a top connected to the hanging frame 8. The lifting sleeve 6 and the adjusting screw 4, the upper part of the liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com