Mineral decolorant and preparation method thereof

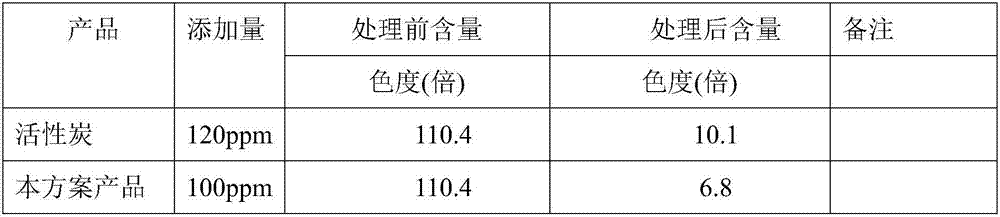

A decolorizing agent and mineral technology, applied in the field of decolorizing agent preparation, can solve the problems of large amount of addition, high unit price, high processing cost, etc., and achieve the effect of low cost and high cost performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In the present embodiment, the mineral decolorizing agent is aluminosilicate, and the aluminosilicate comprises the following components in mass percent: 65% SiO 2 , 19% Al 2 o 3 , 1% K 2 O, 2% Na 2 O, 1% CaO, 3% MgO, 2% Fe 2 o 3 and 7% H 2 O.

[0025] Described mineral decolorizing agent is made by following method, and concrete steps comprises:

[0026] Crush the mineral product into 180 mesh mineral powder, add the mineral powder into the water according to the solid-liquid ratio of 1:7, and stir at a speed of 100 rpm for 0.5 hours to obtain the mineral powder solution; add a dispersant to the mineral powder solution And stir, the mass ratio of dispersant and mineral powder solution is 1:10000; screen out the selected mineral powder; add the selected mineral powder into the acid solution with a concentration of 0.8 mol / liter according to the ratio of solid to liquid ratio of 1:2 , under the condition of 60° C. for 1 hour to obtain an activated product; wash t...

Embodiment 2

[0034] In the present embodiment, the mineral decolorizing agent is aluminosilicate, and the aluminosilicate includes the following components in mass percent: 70% SiO 2 , 13% Al 2 o 3 , 0.5% K 2 O, 2% Na 2 O, 1.5% CaO, 3% MgO, 2% Fe 2 o 3 and 8% H 2 O.

[0035] Described mineral decolorizing agent is made by following method, and concrete steps comprises:

[0036] Crush the mineral product into 190 mesh mineral powder, add the mineral powder into water according to the solid-liquid ratio of 1:8, and stir at a speed of 110 rpm for 0.7 hours to obtain a mineral powder solution; add a dispersant to the mineral powder solution And stir, the mass ratio of dispersant and mineral powder solution is 2:10000; screen out the selected mineral powder; add the selected mineral powder into the acid solution with a concentration of 1.5 mol / liter according to the ratio of solid to liquid ratio of 1:3 , activating at 70°C for 5 hours to obtain an activated product; washing the activat...

Embodiment 3

[0044] In the present embodiment, the mineral decolorizing agent is aluminosilicate, and the aluminosilicate comprises the following components in mass percent: 69% SiO 2 , 17% Al 2 o 3 , 1% K 2 O, 1.5% Na 2 O, 1% CaO, 3.5% MgO, 2% Fe 2 o 3 and 5% H 2 O.

[0045] Described mineral decolorizing agent is made by following method, and concrete steps comprises:

[0046] Crush the mineral products into 200-mesh mineral powder, add the mineral powder into water according to the solid-liquid ratio of 1:10, and stir at a speed of 120 rpm for 1 hour to obtain a mineral powder solution; add a dispersant to the mineral powder solution And stir, the mass ratio of dispersant and mineral powder solution is 3:10000; screen out the selected mineral powder; add the selected mineral powder to the acid solution with a concentration of 2 mol / liter according to the ratio of solid to liquid ratio of 1:4 , under the condition of 80° C. for 8 hours to obtain an activated product; wash the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com