Preparing method for nickel plating glass fiber fabric/epoxy resin electromagnetic shielding composite material

A technology of glass fiber and epoxy resin, which is applied in the field of preparation of nickel-plated glass fiber fabric/epoxy resin electromagnetic shielding composite materials, which can solve the problems of high price and industrialization of the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 Preparation of nickel-plated glass fiber fabric

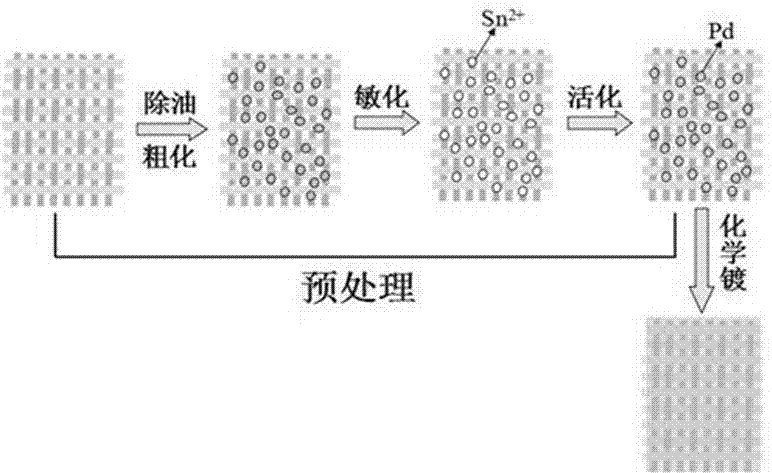

[0027] (1) Surface pretreatment of glass fiber fabric:

[0028]Put the glass fiber fabric in the acetone solution, shake it at a constant temperature of 30°C for 20 minutes, and wash it for later use; add the degreased glass fiber fabric into the roughening solution, shake it at a constant temperature of 60°C for 40 minutes, and wash it for later use; Add the glass fiber fabric into the sensitizing solution, shake it at a constant temperature for 20 minutes at 35°C, and wash it for later use; add the sensitized glass fiber fabric into the activation solution, shake it at a constant temperature for 20 minutes at 30°C, and wash it for later use. The composition of the roughening solution is: sodium hydroxide 40g / L; the composition of the sensitization solution is: 30g / L of stannous chloride, 20ml / L of hydrochloric acid of 37wt.%, and the solvent is distilled water; the composition of the activation solution is...

Embodiment 2

[0032] Embodiment 2 Preparation of nickel-plated glass fiber fabric

[0033] (1) Surface pretreatment of glass fiber fabric:

[0034] Put the glass fiber fabric in the acetone solution, shake it at a constant temperature of 30°C for 20 minutes, and wash it for later use; add the degreased glass fiber fabric into the roughening solution, shake it at a constant temperature of 60°C for 40 minutes, and wash it for later use; Add the glass fiber fabric into the sensitizing solution, shake it at a constant temperature for 20 minutes at 35°C, and wash it for later use; add the sensitized glass fiber fabric into the activation solution, shake it at a constant temperature for 20 minutes at 30°C, and wash it for later use.

[0035] The composition of the roughening solution is: sodium hydroxide 40g / L; the composition of the sensitization solution is: 30g / L of stannous chloride, 20ml / L of hydrochloric acid of 37wt.%, and the solvent is distilled water; the composition of the activation s...

Embodiment 3

[0039] Embodiment 3 Preparation of nickel-plated glass fiber fabric

[0040] (1) Surface pretreatment of glass fiber fabric:

[0041] Put the glass fiber fabric in the acetone solution, shake it at a constant temperature of 30°C for 20 minutes, and wash it for later use; add the degreased glass fiber fabric into the roughening solution, shake it at a constant temperature of 60°C for 40 minutes, and wash it for later use; Add the glass fiber fabric into the sensitizing solution, shake it at a constant temperature for 20 minutes at 35°C, and wash it for later use; add the sensitized glass fiber fabric into the activation solution, shake it at a constant temperature for 20 minutes at 30°C, and wash it for later use.

[0042] The composition of the roughening solution is: sodium hydroxide 40g / L; the composition of the sensitization solution is: 30g / L of stannous chloride, 20ml / L of hydrochloric acid of 37wt.%, and the solvent is distilled water; the composition of the activation s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com