Planetary multi-stage transmission

A technology of planetary gears and planetary gear sets, applied in the direction of vehicle gearboxes, components with teeth, gear transmissions, etc., can solve the problems of large installation space, increase consumption, increase manufacturing costs, etc. The effect of benefiting the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

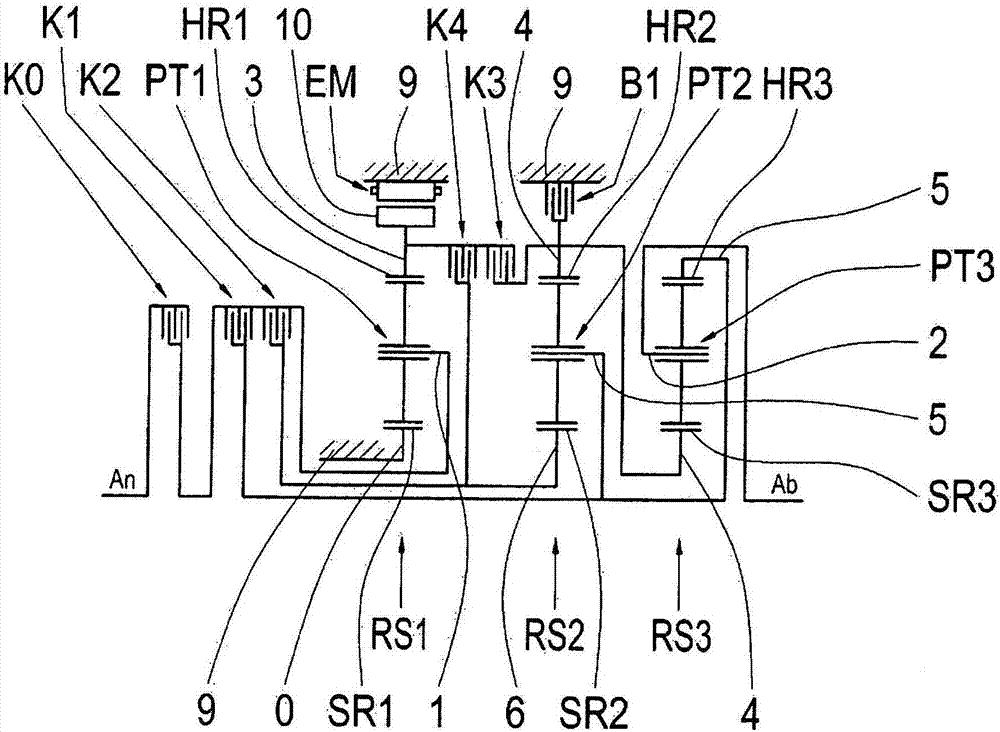

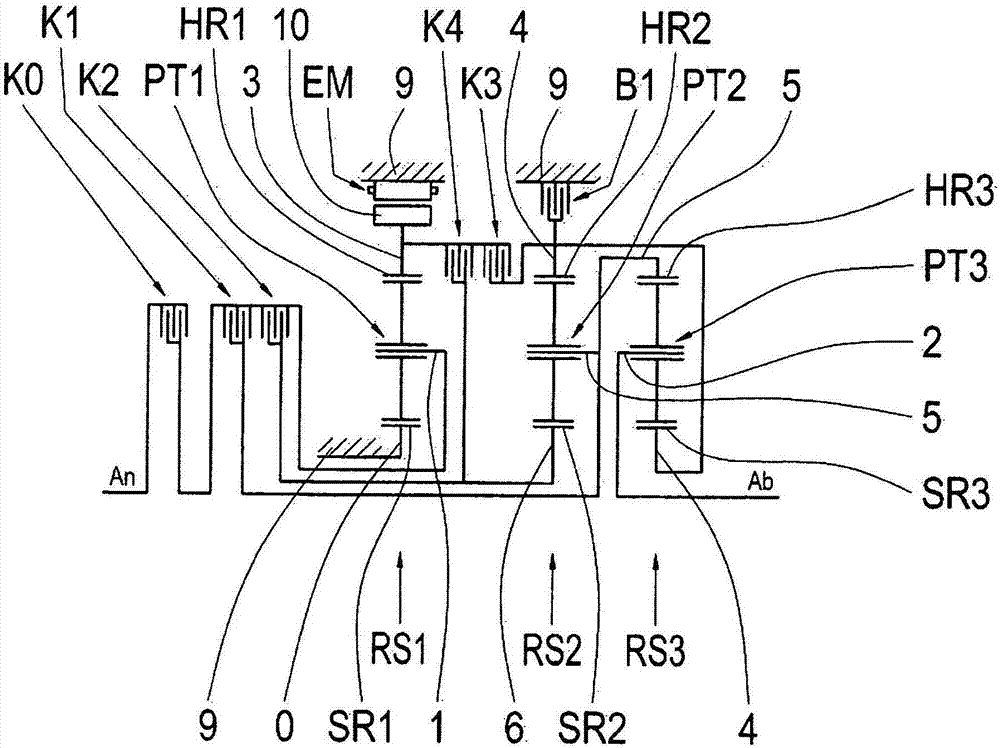

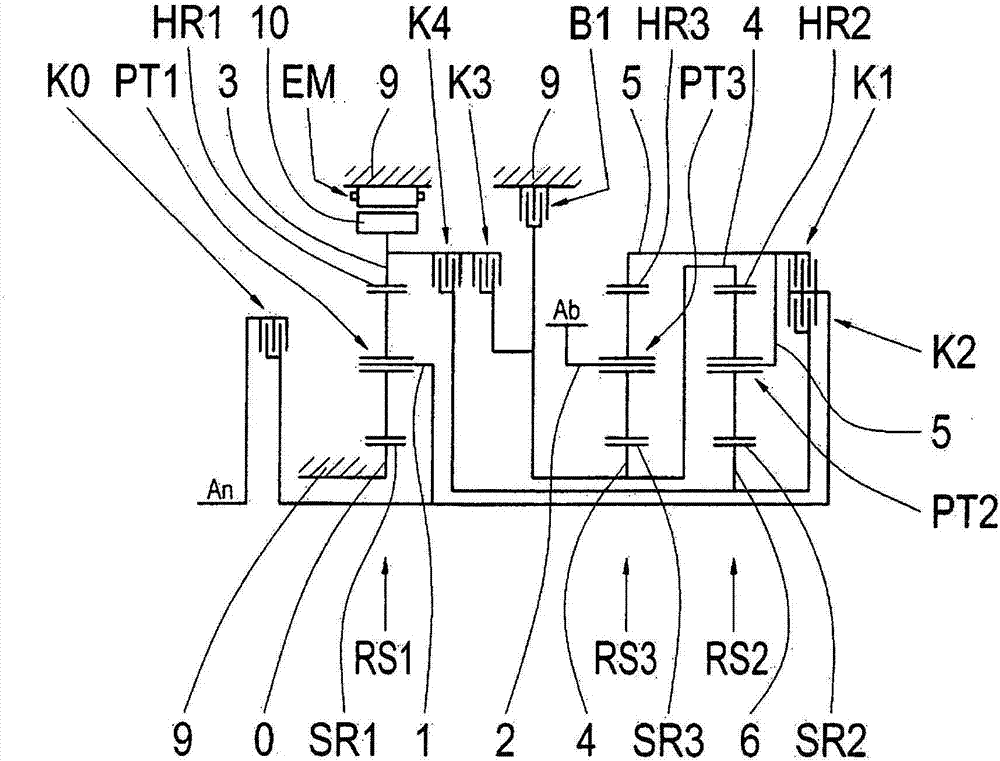

[0032] Figures 1 to 9 Various embodiments of the multi-stage transmission according to the invention for vehicles, in particular motor vehicles, in planetary gear construction, for example as an automatic eight-speed transmission or an automatic transmission, are shown, Figure 10 An example of a shift map for realizing the different gears is shown.

[0033] Regardless of the specific embodiment, the multi-stage transmission is only shown schematically as a gear set with a housing 9 . The drive unit An and the output unit Ab are likewise shown schematically, for example as an internal combustion engine. The proposed multi-stage transmission comprises six shafts 1 , 2 , 3 , 4 , 5 , 6 and a fixed housing coupling 0 . Furthermore, at least one electric machine EM as well as a first planetary gear set RS1 , a second planetary gear set RS2 and a third planetary gear set RS3 are provided, wherein the drive unit An, for example as an internal combustion engine, can be operated via...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com