Structure of flexible printed circuit board

一种柔性印制、电路板的技术,应用在印刷电路、印刷电路、印刷电路零部件等方向,能够解决焊盘撕裂、降低柔性印制电路板调整组装公差的作用、产品失效等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

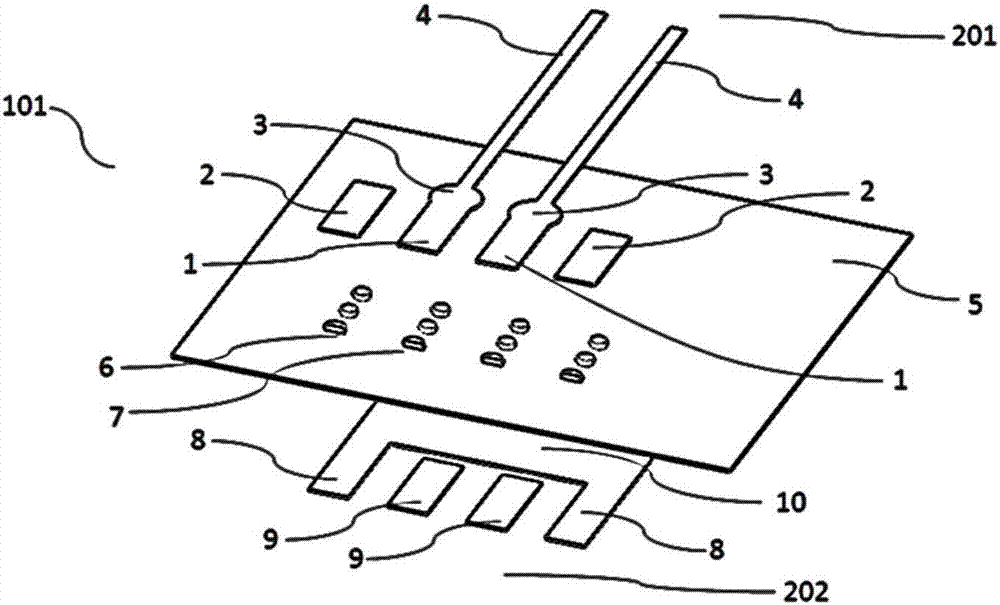

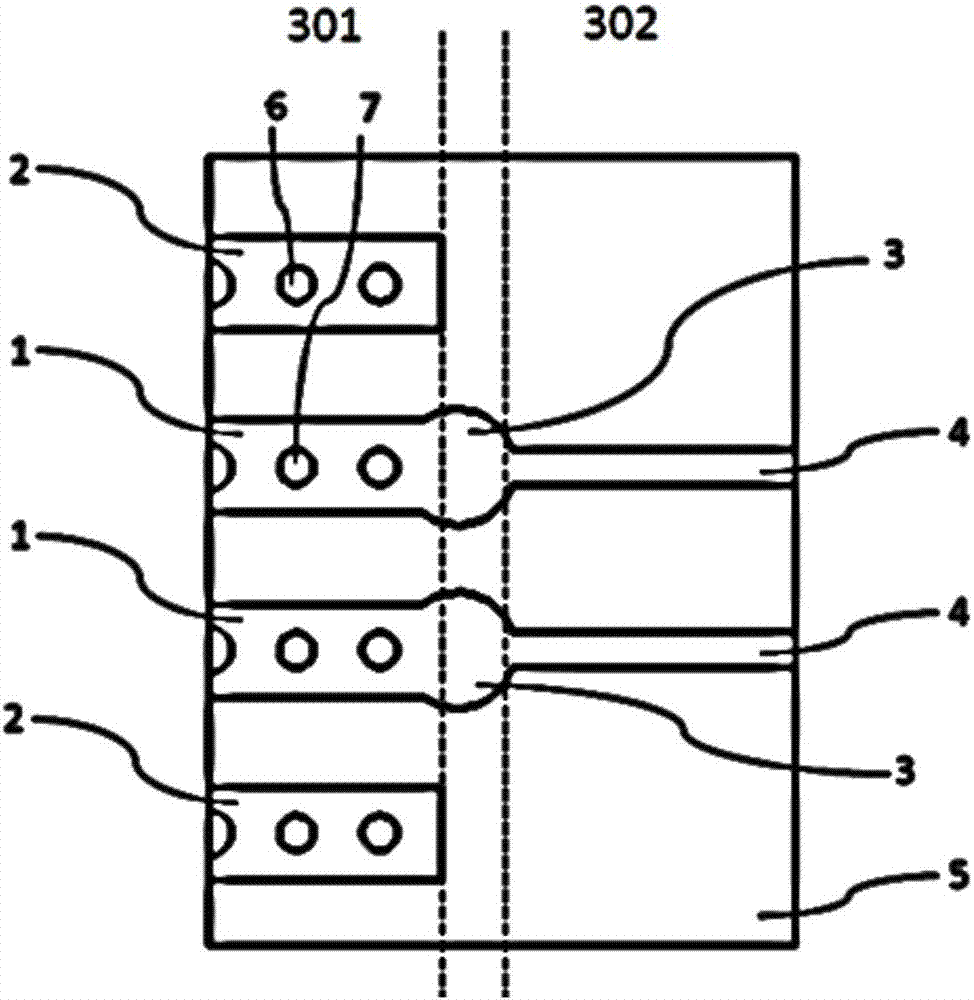

[0021] Such as Figure 1-4 As shown, the flexible printed circuit board 101 of the present invention has a structure of a first conductor layer 201 , a second conductor layer 202 and a dielectric layer 5 .

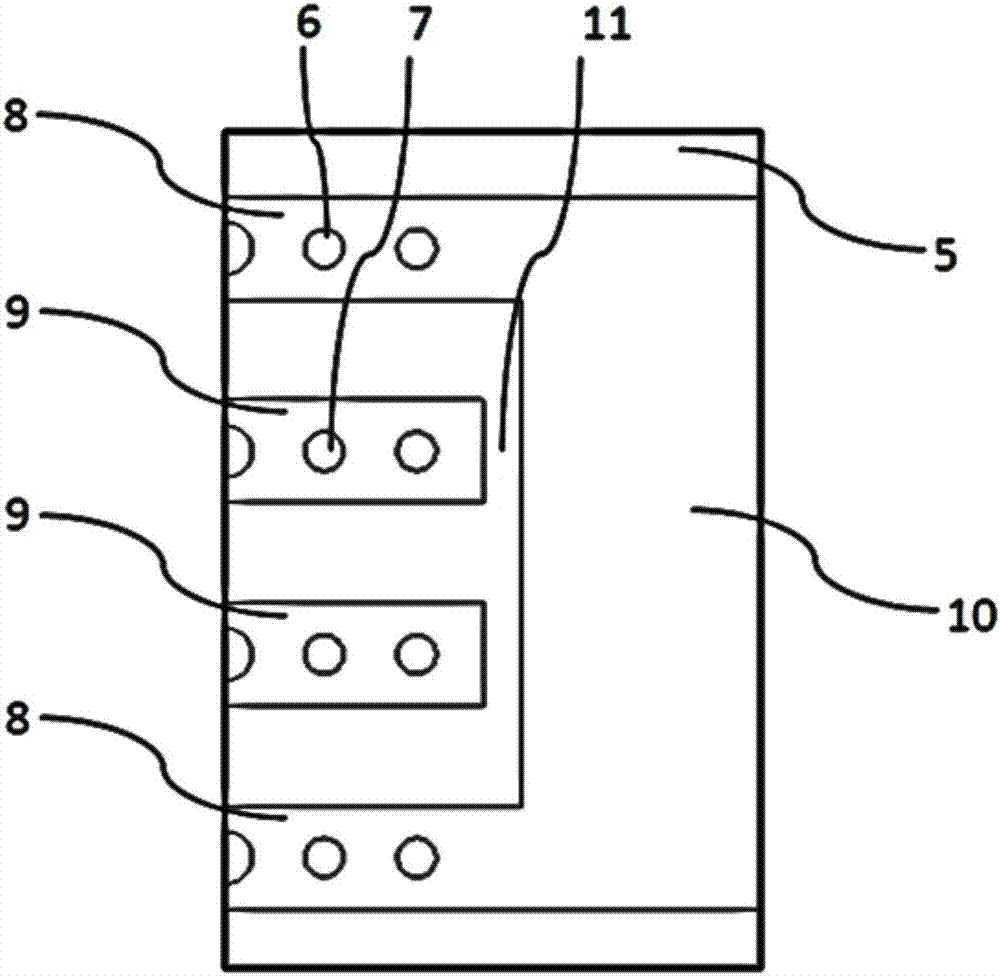

[0022] The flexible printed circuit board 101 of the present invention has a pad portion 301 electrically connected to the outside, and a line portion 302 for transmitting signals. The line portion 302 is a differential line of a microstrip line formed between the signal line 4 of the first conductor layer 201 and the ground layer 10 of the second conductor layer 202 . The pad part 301 is composed of the first signal pad 1 and the first ground pad 2 on the first conductor layer 201 , and the second signal pad 9 and the second ground pad 8 on the second conductor layer 202 . The electrical connection between the first signal pad 1 and the second signal pad 9 is realized through the signal pad via hole 7 . The first ground pad 2 and the second ground pad 8 are electrically...

Embodiment 2

[0025] The structure of the flexible printed circuit board in this embodiment is basically the same as that in Embodiment 1, except that the flexible printed circuit board 101 exists between the pad portion 301 and the line portion 302 of the first conductor layer 201 Next to the conductor transition area 3, the conductor transition area 3 is located between the first signal pad and its corresponding signal line, and the conductor width in the conductor transition area changes as follows: it first becomes wider than the first signal pad, It is then narrowed to the same width as the signal line. Between the pad portion 301 and the line portion 302 of the second conductor layer 202 there is a gap 11 for electrically separating the signal pad and the ground layer.

[0026] From Figure 4 From the perspective view of the flexible printed circuit board, it can be seen that the conductor transition zone 3 is located just above the electrical separation gap for compensating its impe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com