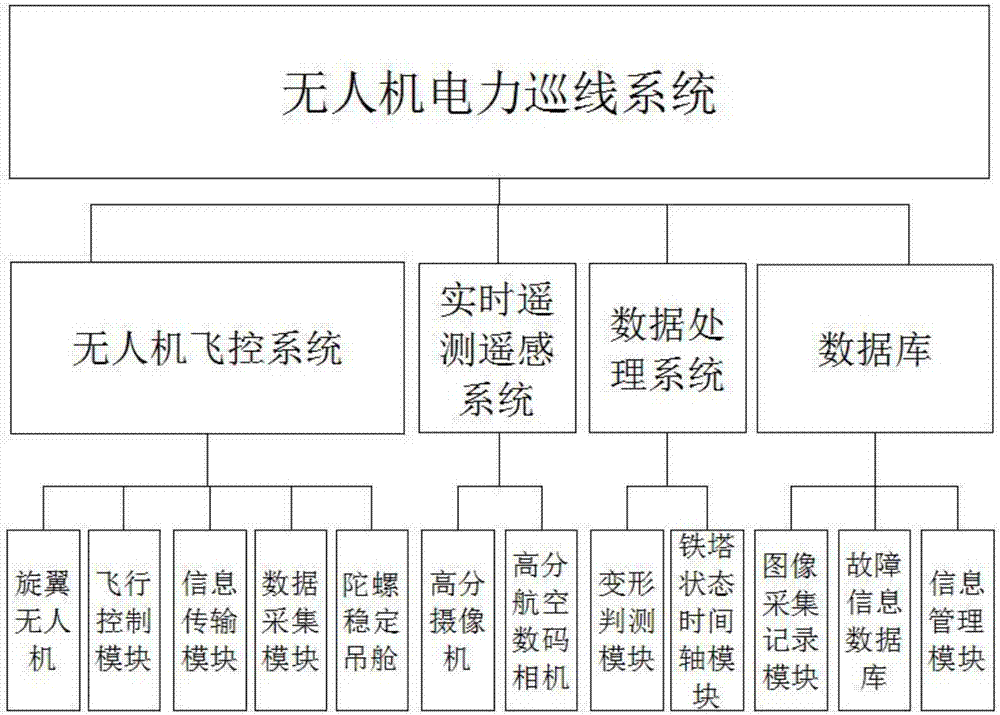

Rotor unmanned aerial vehicle power line inspection system

A technology of unmanned rotor and electromechanical power, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of heavy workload, high risk of manual line inspection, high labor intensity, etc., achieve low requirements, improve line inspection efficiency, and The effect of fast line speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

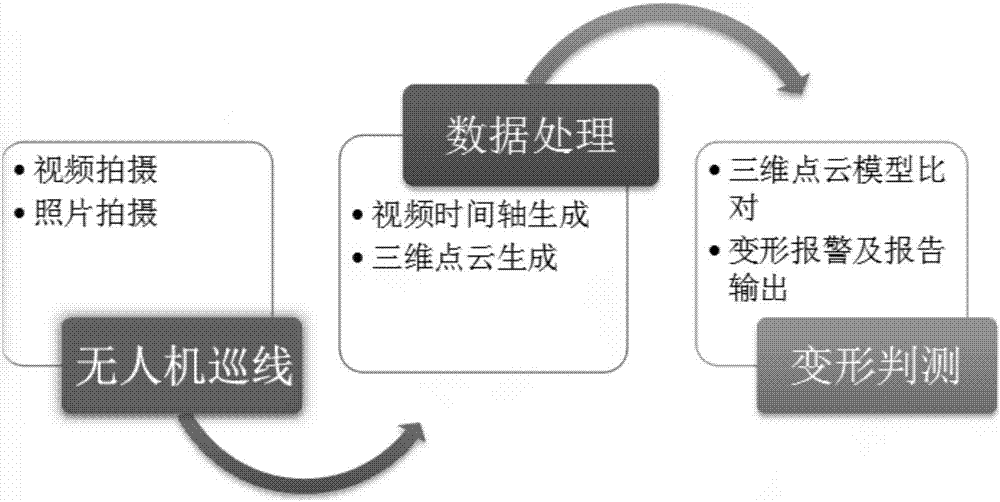

[0023] The specific implementation is as follows: the combination of the real-time telemetry and remote sensing system and the data processing system can achieve close-range stereo image matching and data collection management. The close-range stereo image matching is based on the base distance between cameras of the airborne stereo photography system, based on grayscale projection and The epicenter-constrained stereoscopic image matching algorithm realizes the rapid automatic matching of the same-named image points in the airborne stereoscopic image; for the CCD stereoscopic photography system in the airborne system, using the relatively mature spatial data acquisition system for GIS applications, the system Based on the AO component, the stereoscopic measurement embedded in the airborne CCD image realizes the integrated organization, management and data processing of GPS, INS, CCD image and basic geographic data, and directly collects, edits and processes vector geographic inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com