Machine tool selection method facing highest energy efficiency during whole usage stage of machine tool

A technology of energy efficiency and machine tools, applied in computer control, general control system, program control, etc., can solve problems such as inaccurate evaluation of energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] A method for selecting a machine tool with the highest energy efficiency for the entire use period of the machine tool, including the following steps:

[0051] Step 1: Establish the expected processing workpiece set W T :W T =[W 1 ,...,W l ,...,W L ]; Among them, L is the total number of types of workpieces to be processed, 1≤l≤L;

[0052] Step 2: Establish a set of candidate machine tools MT: MT=[MT 1 ,...,MT m ,...,MT M ]; where M is the total number of candidate ensemble categories, 1≤m≤M;

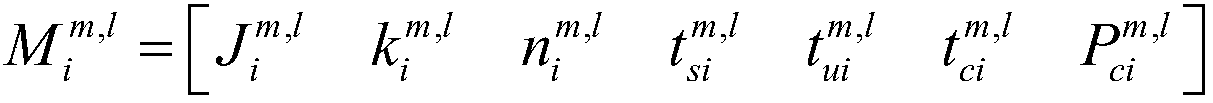

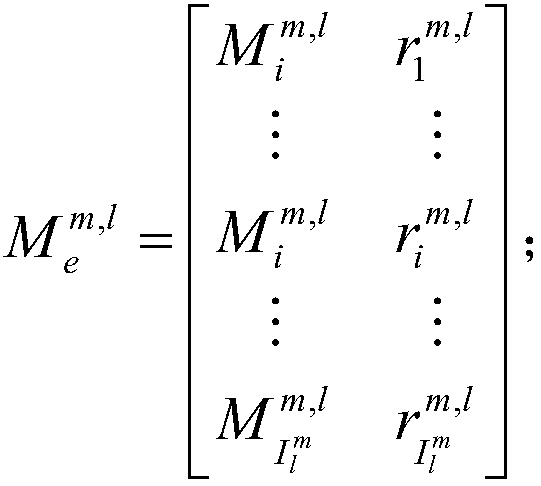

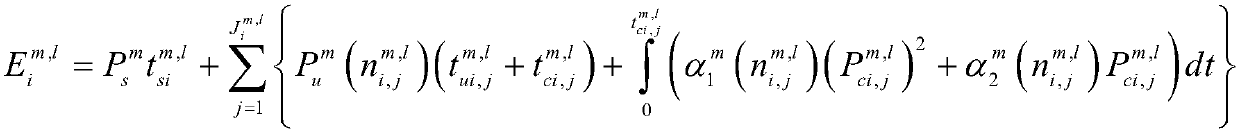

[0053] Step 3: Establish the inherent energy efficiency characteristic matrix for each candidate machine tool in the candidate machine tool set MT, the mth candidate machine tool MT m The intrinsic energy efficiency characteristic matrix of in, Candidate Machine Tool MT m the standby power, Candidate Machine Tool MT m energy consumed during the spindle startup phase, Candidate Machine Tool MT m no-load power, Candidate machine tool MT m The primary and secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com