A cumulative slip construction method for space grid truss structures

A truss structure and space grid technology, applied in building construction, building material processing, construction, etc., can solve problems such as high cost of measures and high safety risks, and reduce investment in temporary measures, reduce safety risks, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

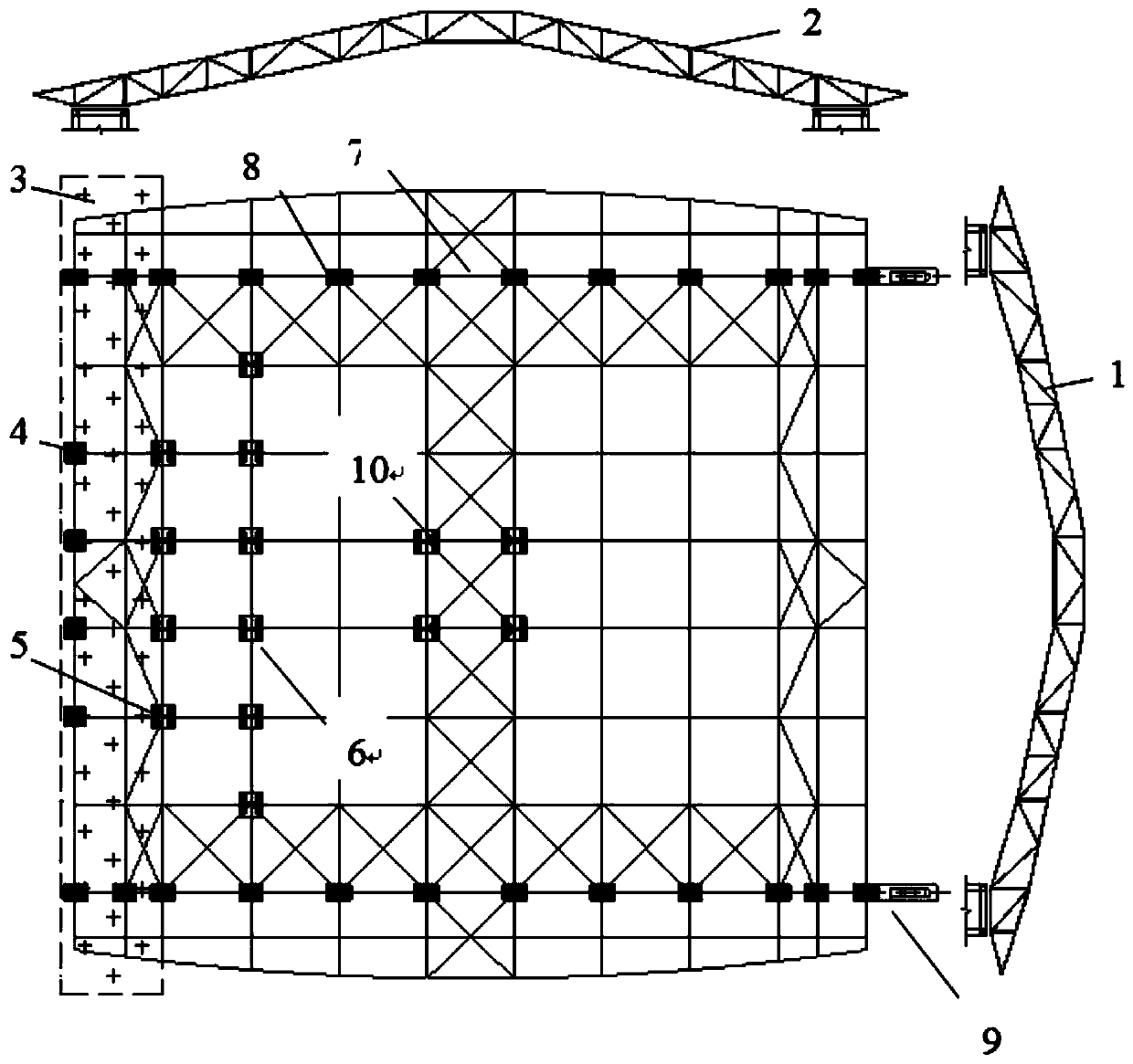

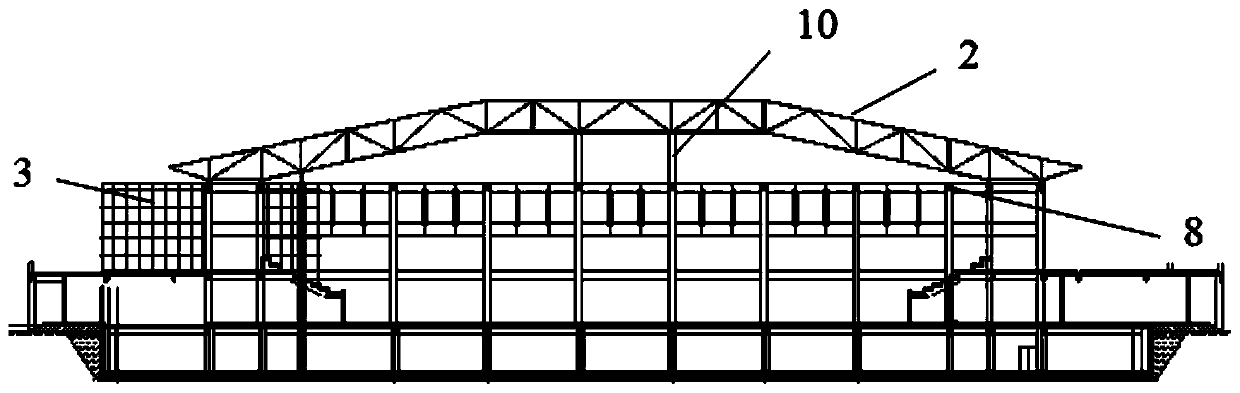

[0025] See attached picture.

[0026] A construction method for accumulative slippage of a space grid truss structure, characterized in that:

[0027] (1) First, set up the assembly platform 3 on the side span, set up the assembly support 4 at the corresponding position of the side column network, and according to the calculation and analysis of the sliding condition, set the anti-tension support 5 and the jacking support 6 at the corresponding position of the second span column network ;

[0028] (2) Secondly, a stainless steel slideway 7 in the longitudinal direction is set above the concrete beam at the existing support level, and a horizontal jack and a hydraulic control system 9 are installed at the front end of the stainless steel slideway;

[0029] (3) Install two horizontal trusses 1 on the assembled bracket, and install the longitudinal truss 2 between the two horizontal trusses, set the anchor member at the front end of the truss, and then place the slider 8 under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com