Detachable type tripod post-cast strip independent supporting system and use method thereof

A support system and post-casting technology, which is applied in the field of formwork/formwork/work frame, construction components on-site preparation, construction, etc., can solve the problems of increasing the rental cost of surrounding materials, reducing construction transportation capacity, and long backlog time , to achieve the effect of improving the guarantee degree of implementability and construction quality, considerable economic benefits, and less surrounding material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing.

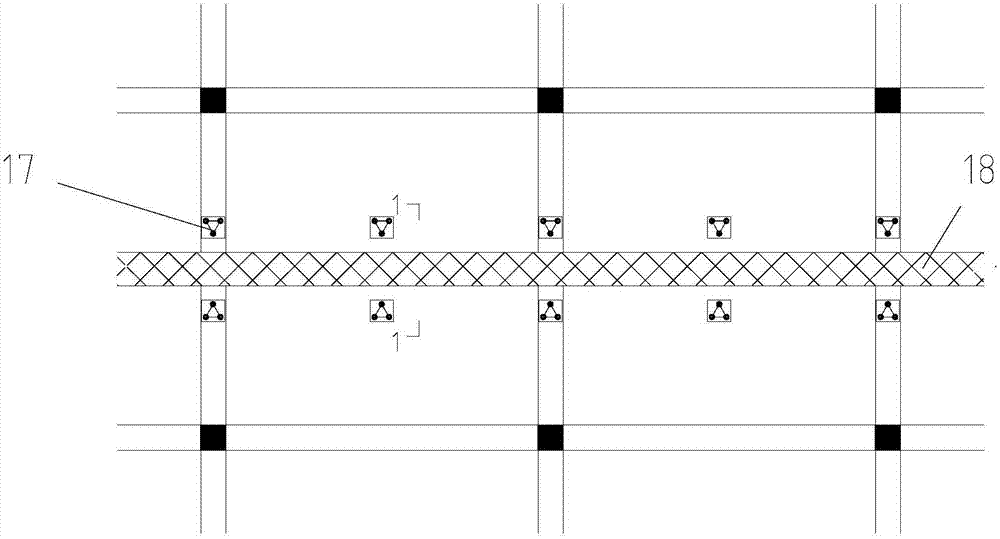

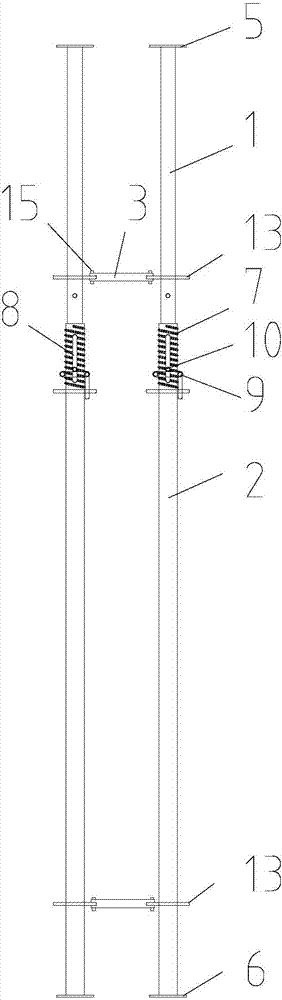

[0038] see Figure 1 to Figure 8 , the detachable tripod post-casting belt independent support system is formed by several steel upright groups, each group of steel uprights is composed of three adjustment uprights, and the three adjustment uprights are connected by multiple sets of connecting cross bars 3 to form a product glyph combination.

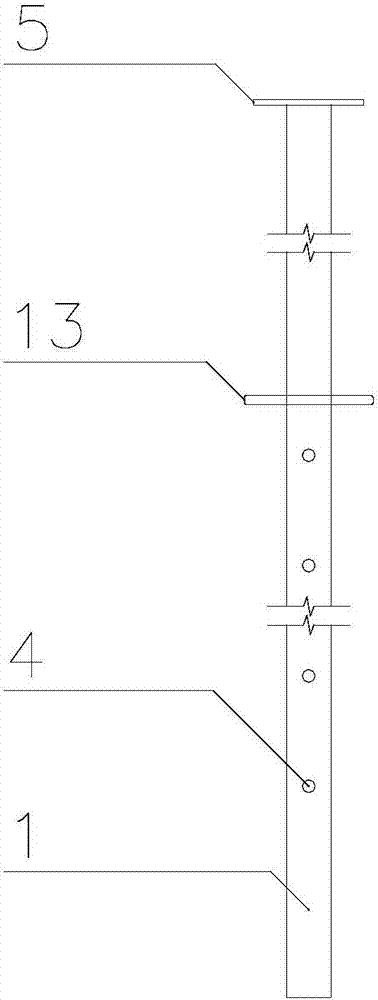

[0039] Specifically, the adjustment pole is composed of an upper pole 1 and a lower pole 2, the top of the upper pole 1 is provided with a jacking 5, and the upper pole 1 is provided with a plurality of radially perforated limit pin holes along the axial direction. 4. The length of the lower pole is 2000mm. The bottom of the lower pole 2 is provided with a bottom support 6, and the upper end is provided with a fine-tuning screw area 7. The fine-tuning screw area 7 is screwed with a fine-tuning knob 9. The fine-tuning screw area 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com