Two-way convection graded drop energy dissipation shaft

A drop-type, vertical shaft technology, which is applied in sea area engineering, construction, barrage/weir, etc., can solve the problems of excessive flow velocity, large difference in water surface inside and outside the flow, and low space utilization, so as to reduce the water level and flow velocity, The structure is compact and the energy dissipation effect is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

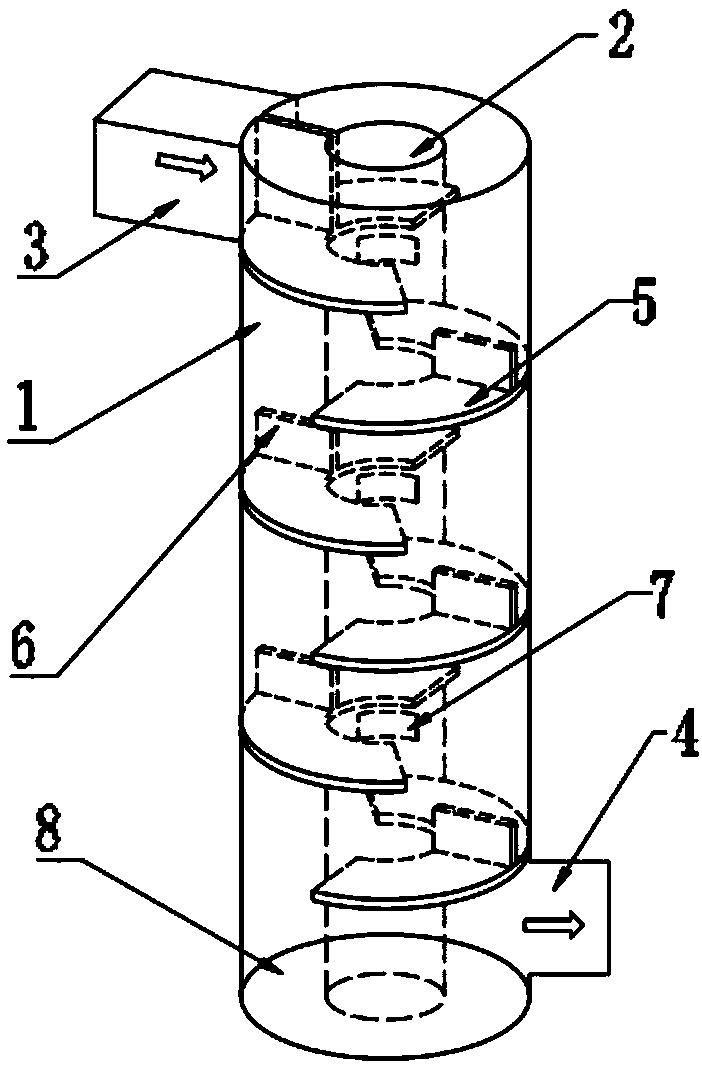

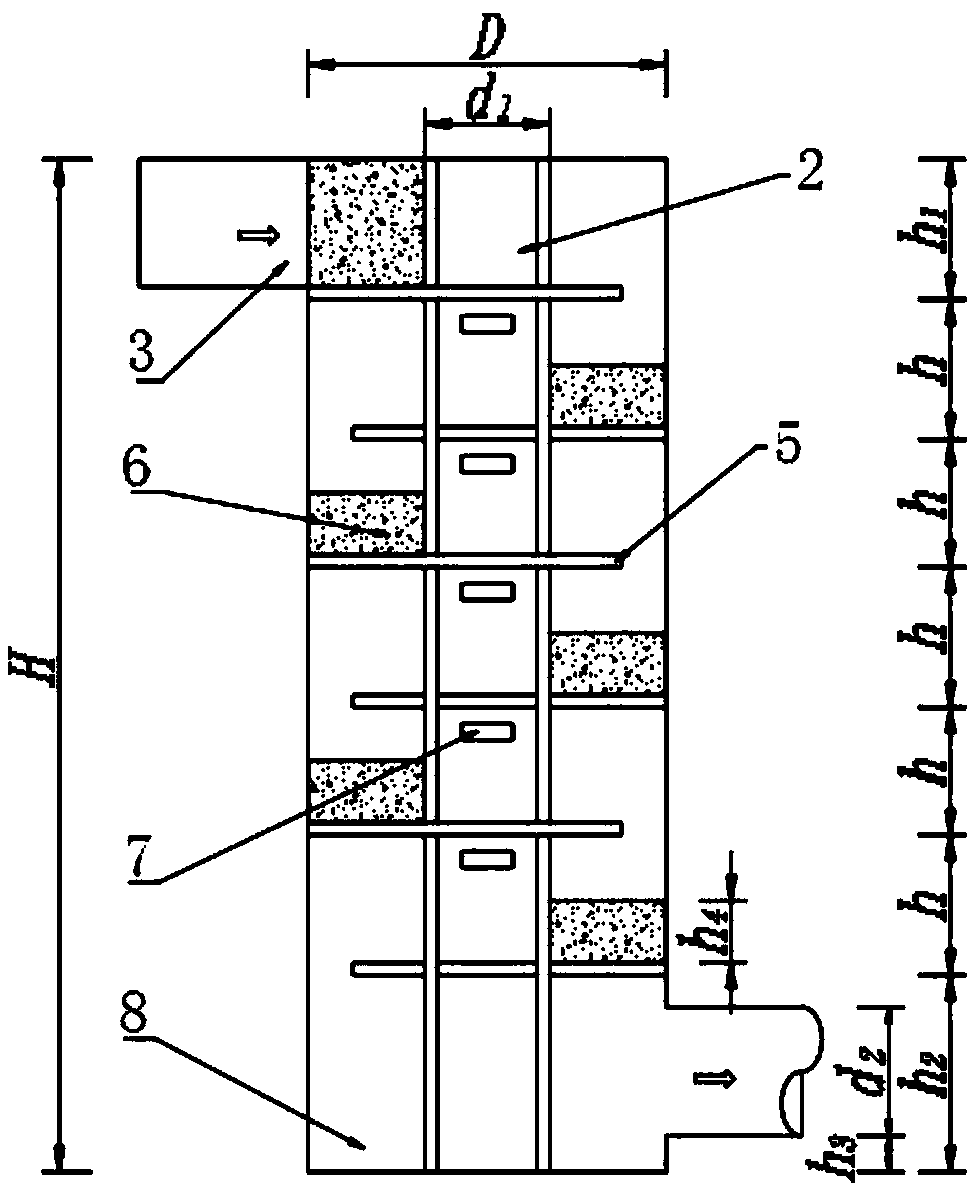

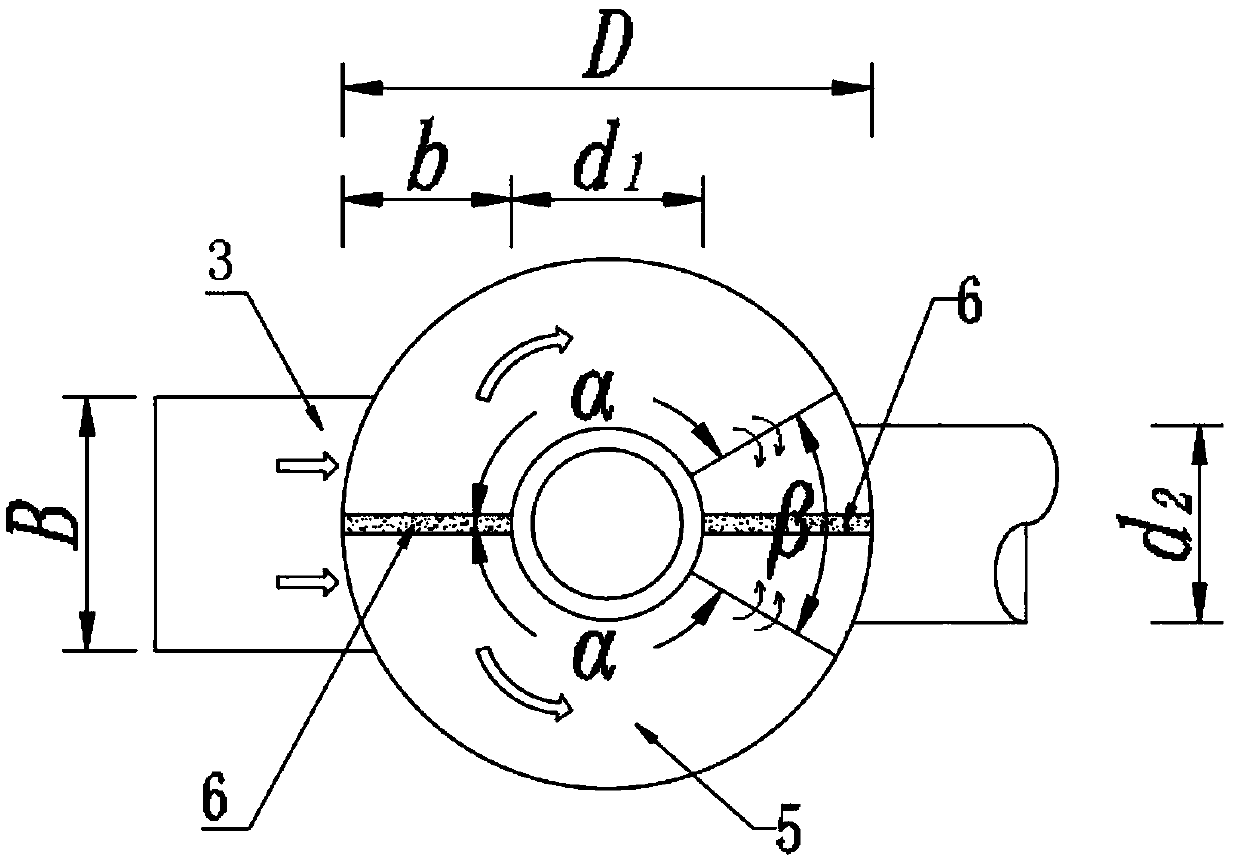

[0029] In the embodiment, the structural arrangement of the two-way convection graded drop-type energy dissipation shaft is as follows: figure 1 , figure 2 , image 3 As shown, the two-way convection graded drop energy dissipation shaft includes a shaft 1, an exhaust pipe 2, a water inlet 3, a storage tunnel access port 4, a drop plate 5, a diverter plate 6, a ventilation hole 7 and a water cushion 8. Among them, the number of drop plates 4 is 6. The drop plate 5 and the diverter plate 6 on the first floor are respectively connected with the water inlet channel 3, and the elevation of the drop plate 5 on the bottom floor is higher than the elevation of the top of the entrance 4 of the regulation and storage tunnel. The height of the top of the first-layer diverter plate 6 is flush with the top elevation of the shaft 1 , and the height of the remaining diverter plates 6 is lower than the distance between the adjacent upper and lower layers of the drop plates 5 . The exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com