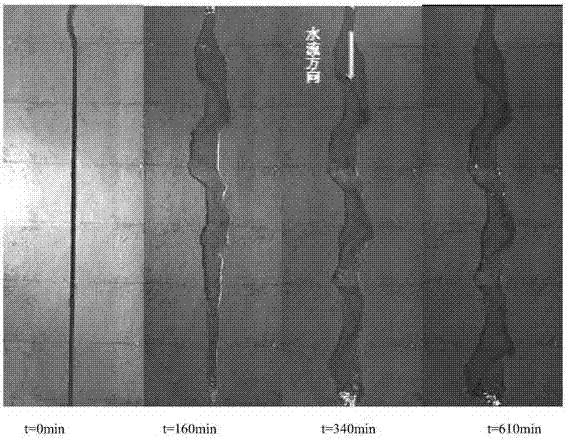

Experimental equipment for simulating water flow and sediment bed-forming process

A technology for simulating water flow and experimental equipment, applied to hydraulic models, etc., can solve the problems of large device scale, small flexibility, time-consuming and labor-consuming, etc., and achieve the effects of improving measurement accuracy, convenient experimental research, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

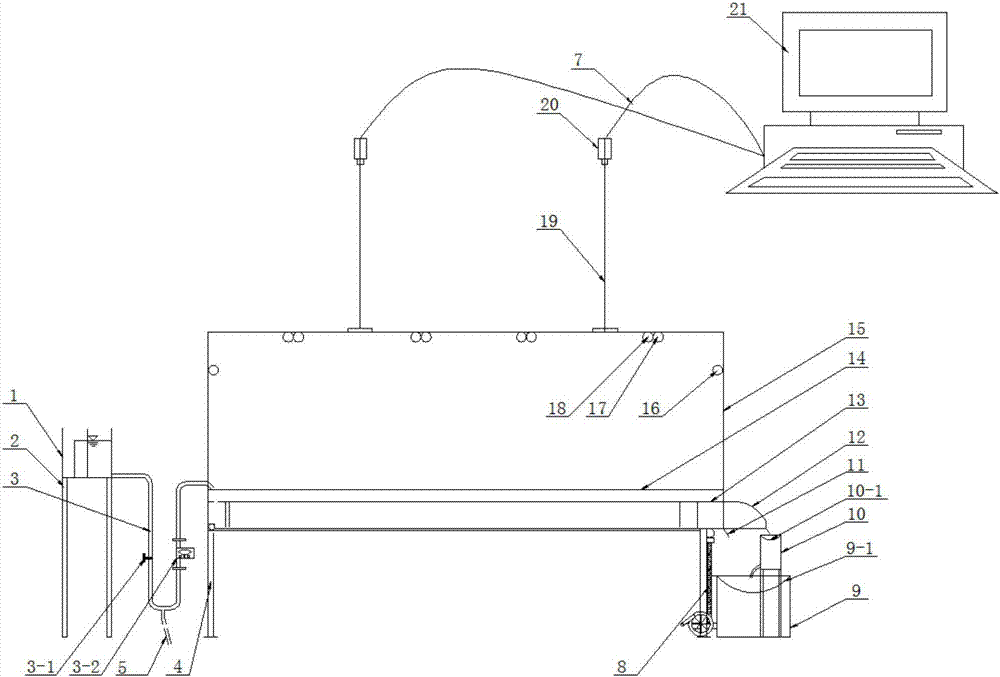

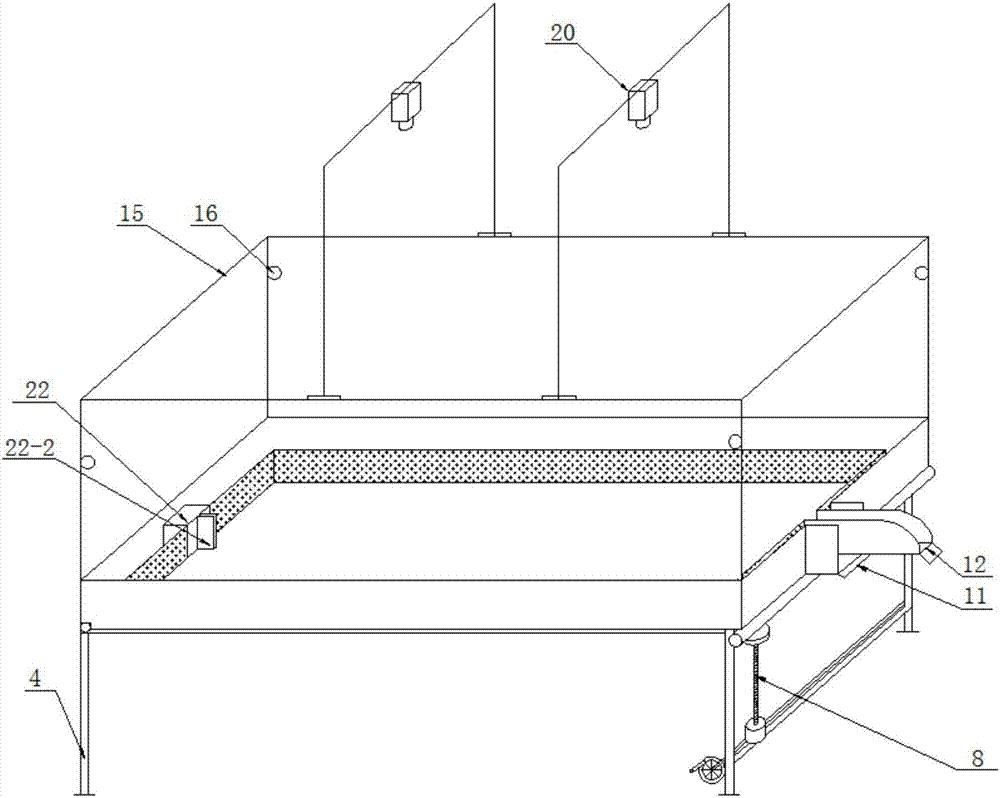

[0039] The present invention will be further described below through specific examples, but the present invention is not limited to the following examples.

[0040] as attached Figures 1 to 8 As shown in the figure, the experimental equipment for simulating the process of water flow and sediment bed formation includes a water supply tank 1, a water inlet pipe 3, a slope adjustment structure 8, a water collection tank 9, a sedimentation bucket 10, a river outflow channel 12, a seepage outflow channel 11, Seepage separation tank 13, water tank 14, experimental shed 15, blower 16, spray pipe 17, lighting pipe 18, image acquisition device 20, processing system 21, water inlet front pool 22;

[0041] The water supply tank 1 is arranged on the first support frame 2, the water tank 14 is arranged on the second support frame 4, the top of the water tank 14 is provided with an experimental shed 15, and the experimental shed 15 is covered on the water tank 14;

[0042]The seepage sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com