A biogas digester with high safety

A biogas digester and safety technology, which is applied in the field of biogas digesters to achieve the effects of increasing storage capacity, improving ease of use and reducing occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

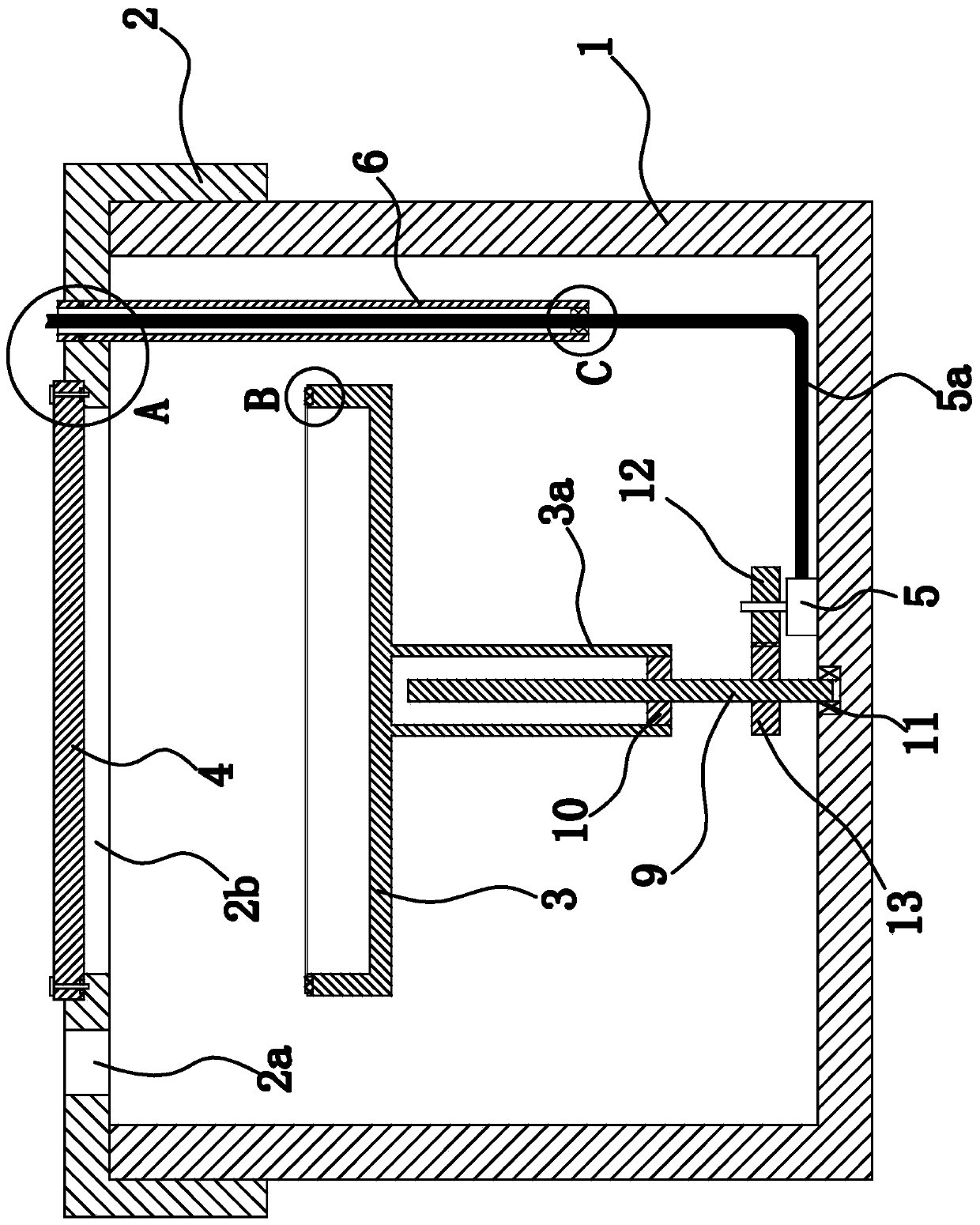

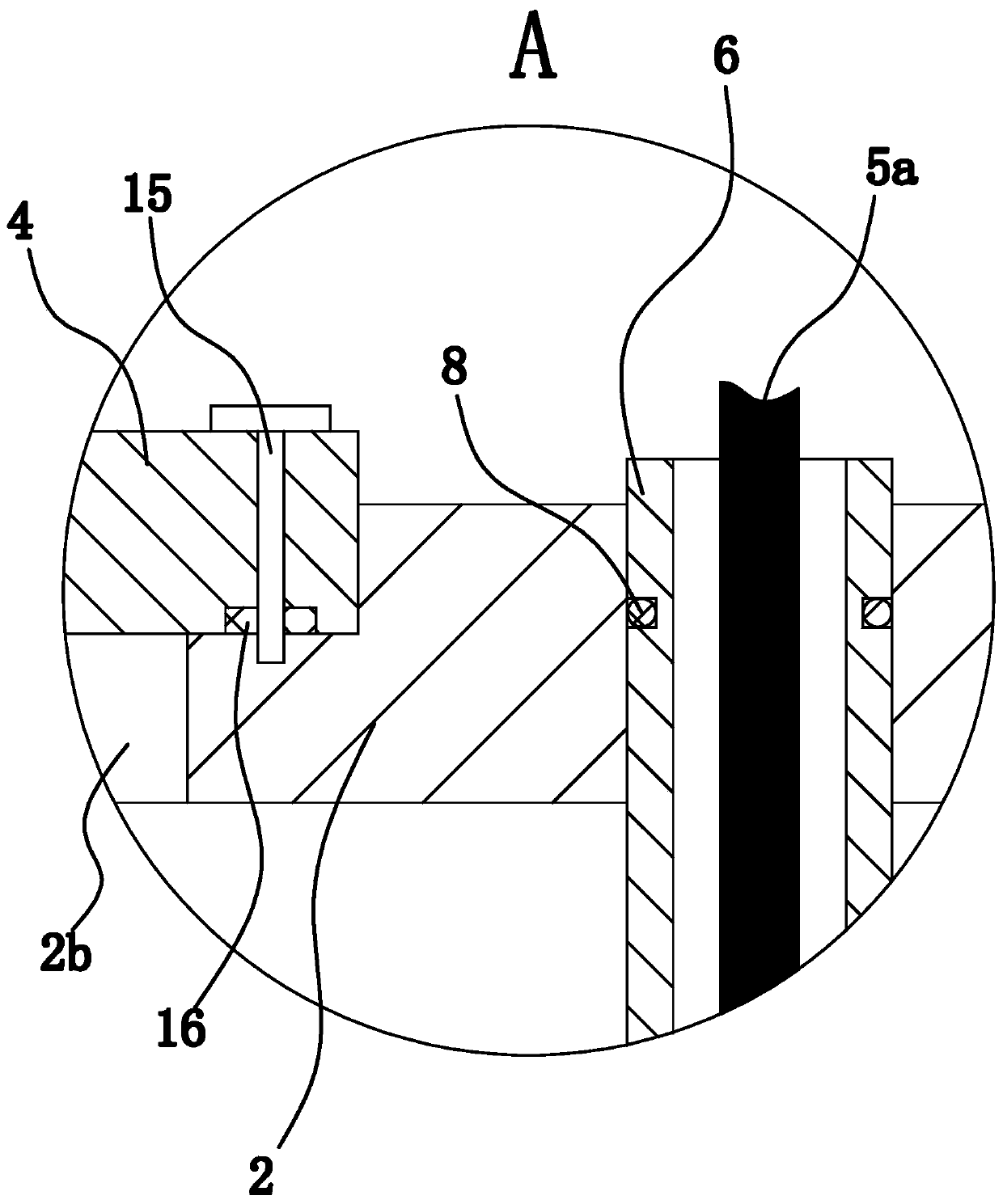

[0039] Such as Figure 1 to Figure 4 As shown, the biogas digester with high safety is composed of a pond body 1, a pond cover 2, a fermentation barrel 3, a sealing plate 4, a motor 5, a connecting pipe 6, a plug 7 and the like.

[0040] Wherein, the pool body 1 is barrel-shaped, and its top is open and its bottom is closed. The pool cover 2 is barrel-shaped, and the pool cover 2 is set on the pool body 1 and the two are fixed together. In this embodiment, the pool body 1 and the pool cover 2 are hermetically fixed together by a tight fit. Such as figure 1 As shown, the pool cover 2 is provided with an air outlet 2a that communicates the inner cavity of the pool body 1 with the outside world, and in actual use, the air outlet 2a is connected to the user pipeline through a valve (not shown).

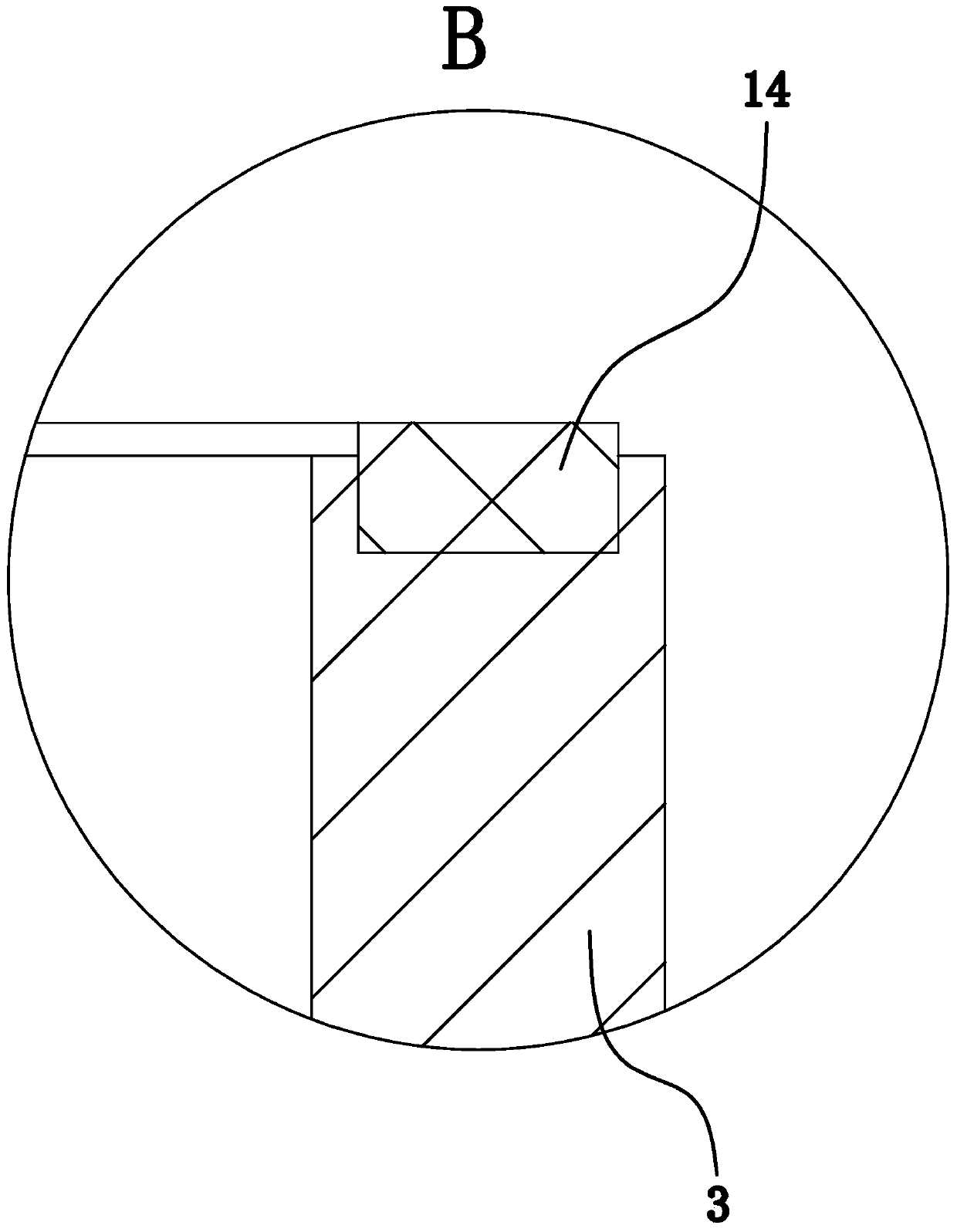

[0041] The fermenter 3 is in the shape of a straight barrel, and the fermenter 3 is vertically arranged in the pool body 1 . Such as figure 1 As shown, the bottom of fermenter 3 is c...

Embodiment 2

[0049] The structure and principle of the present embodiment two are basically the same as those of the first embodiment, except that the transmission mechanism includes a driving wheel fixed on the main shaft of the motor 5 and a driven wheel fixed on the screw mandrel 9, and the driving wheel passes through The timing belt is connected with the driven wheel.

Embodiment 3

[0051] The structure and principle of this third embodiment are basically the same as that of the first embodiment, except that the outer wall of the connecting pipe 6 has an annular shoulder, and the sealing structure includes an annular locking groove and a design on the upper end surface of the annular shoulder. The ring seal is placed in the ring groove, and the two ends of the ring seal are against the bottom wall of the ring groove and the inner top wall of the pool cover 2 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com