Wear-resistant and oil-proof PVC elevator cable material and preparation method thereof

A technology of elevator cable and PVC resin, which is applied in the field of cables, can solve problems affecting customer use, decreased flexibility, and increased hardness of elevator cables, and achieves strong market competitiveness, simple extrusion process, and excellent physical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

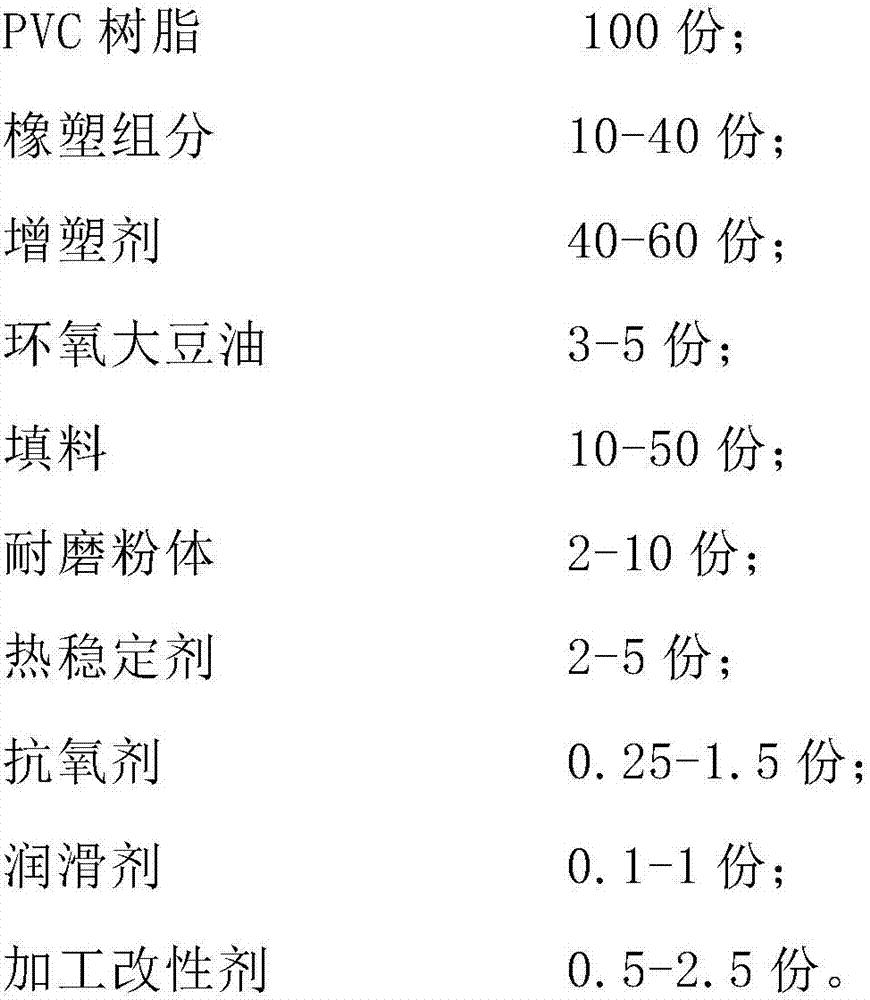

[0030] A kind of wear-resistant and oil-resistant PVC elevator cable material of the present invention, the name of each component and the composition of parts by weight are shown in Table 1:

[0031] Table 1:

[0032]

[0033]

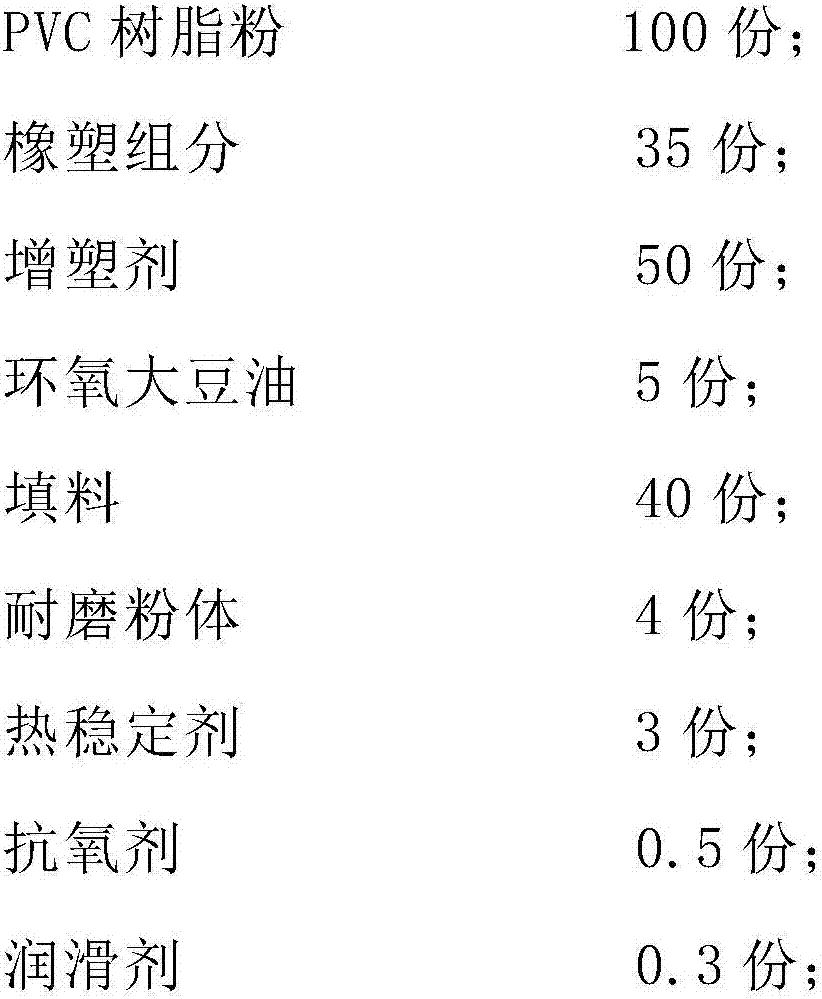

[0034] Table 2 is the raw material component that is specifically used in each embodiment:

[0035] Table 2:

[0036]

[0037] A kind of preparation method of wear-resistant and oil-resistant PVC elevator cable material of the present invention comprises the following steps:

[0038] The first step is to prepare raw materials and accurately weigh each material according to the proportion;

[0039] In the second step, put PVC resin, plasticizer, and epoxy soybean oil into the high-speed kneader, knead at high speed for 3 minutes, then put heat s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com