Accelerator for preparing low-carbon cementitious materials with carbonized steel slag cement and its application method

A cement preparation and accelerator technology, which is applied in the field of accelerators for carbonized steel slag-cement preparation of low-carbon cementitious materials, can solve the problems of affecting the effect of carbonization curing to prepare building materials, and the low strength of carbonization curing, so as to avoid the production process and reduce the strength. Improve and implement the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

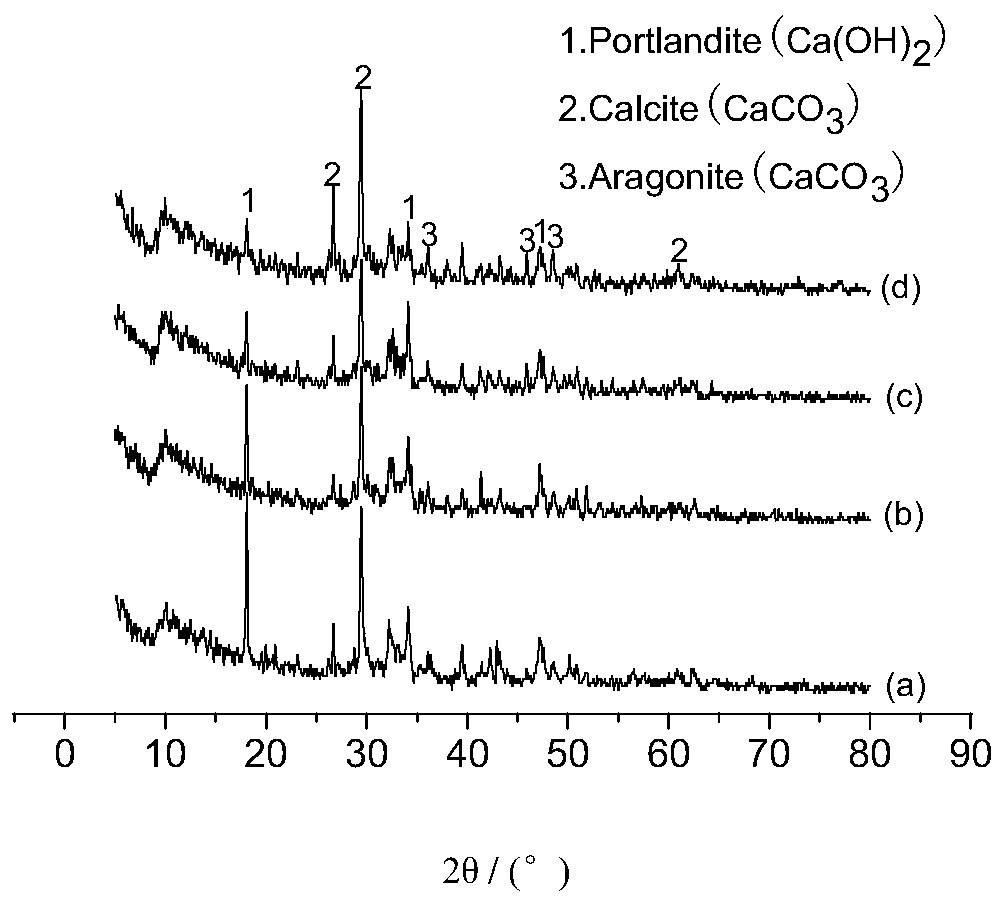

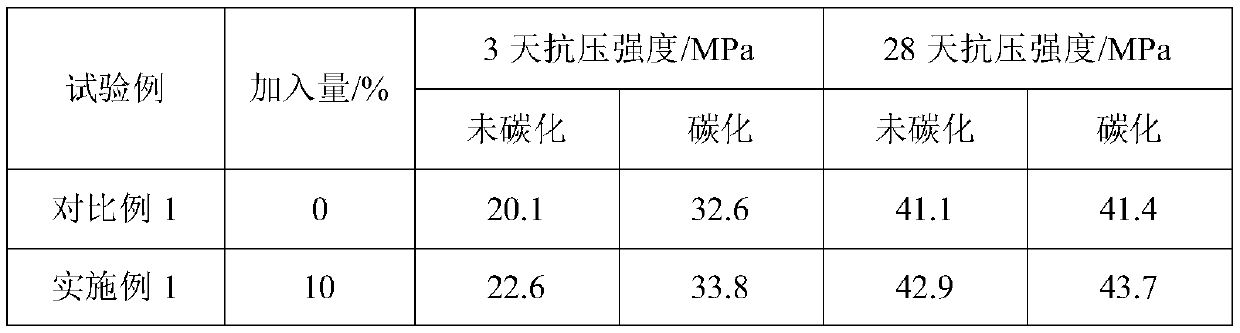

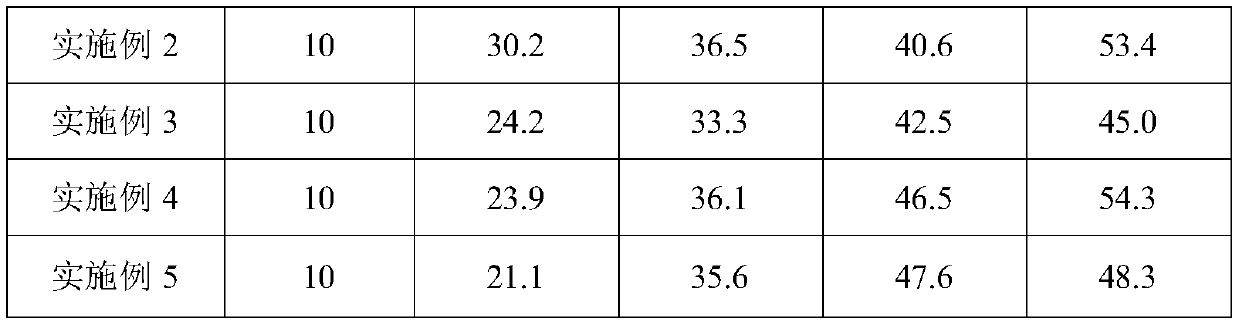

Embodiment 1

[0035] Weigh 70g of cement, 30g of steel slag, CaCO 3 3g, 28g of water, mix and stir evenly, put it into a mold of 20mm×20mm×20mm and vibrate to form, put it in a curing box with a temperature of 20°C and a humidity of 95% for 12 hours to remove the mold, and transfer it to a carbonization kettle for carbonization for 12 hours. For: temperature 90°C, CO 2 Pressure 3MPa. After carbonization, continue to put it into the curing box for curing until 3d and 28d, and test its mechanical properties with an electro-hydraulic servo anti-compression and bending machine.

Embodiment 2

[0037] Weigh 70g of cement, 30g of steel slag, Mg(OH) 23g, 28g of water, mixed and stirred evenly, put into a mold of 20mm×20mm×20mm and vibrate to form, the curing and carbonization method is the same as that of Example 1.

Embodiment 3

[0039] Weigh 70g of cement, 30g of steel slag, Na 2 CO 3 3g, 28g of water, mixed and stirred evenly, put into a mold of 20mm×20mm×20mm and vibrate to form, the curing and carbonization method is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com