Automatic tray unloading and stacking device of cubic seedling machine seedling trays

An automatic unloading and seedling tray technology, which is applied in the stacking of objects, unstacking, transportation and packaging of objects, etc., can solve the problems of restricting the automation degree of seedling machine seedling raising, increasing the production cost of seedling enterprises, and high labor intensity. , to achieve the effect of enriching agricultural facilities and equipment, easy to popularize and use, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

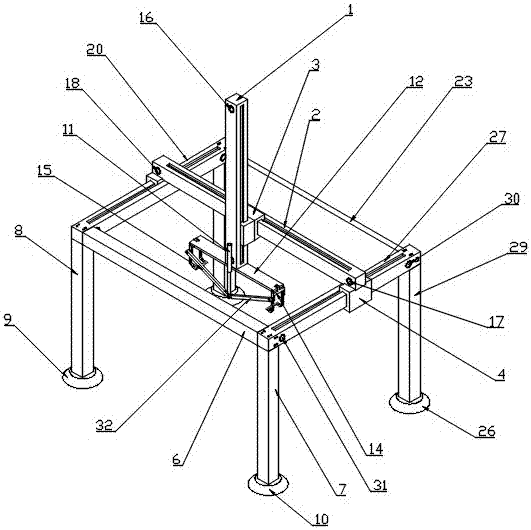

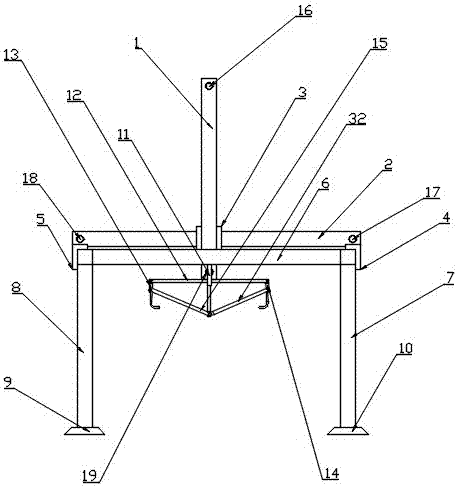

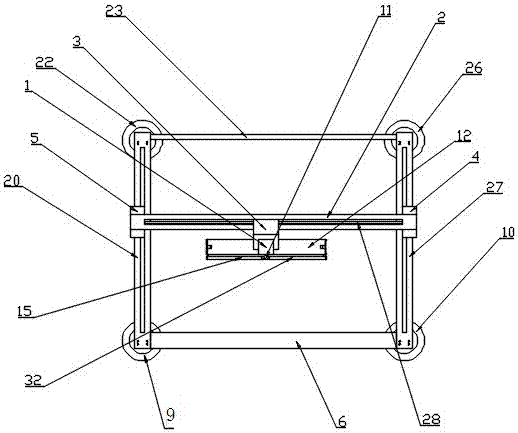

[0020] In order to clearly illustrate the technical characteristics of this solution, the following describes the solution through specific implementations.

[0021] Such as figure 1 An automatic tray unloading and palletizing device of a square sports seedling machine includes a three-way linear sliding table and a support frame fixed on the bottom surface of the three-way linear sliding table. The three-way linear sliding table includes a parallel arrangement and a support The longitudinal horizontal linear guide 20 and the longitudinal horizontal linear guide 27 fixed to the frame, and the horizontal linear guides whose two ends are slidably connected to the longitudinal horizontal linear guide 20 and the longitudinal horizontal linear guide 27 through the longitudinal slider 5 and the longitudinal slider 4 respectively 2. A horizontal slider 3 is slidably connected to the horizontal horizontal linear guide 2, and a vertical chute is also provided on the horizontal slider 3. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com