Combined integrated spanner with spanner head

A wrench head and combined type technology, applied in the field of wrenches, can solve the problems of inconvenient wrench work, inconvenient processing of multiple workpieces, single function of a single hand, etc., and achieve the effects of simple structure, low cost, and reduced carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

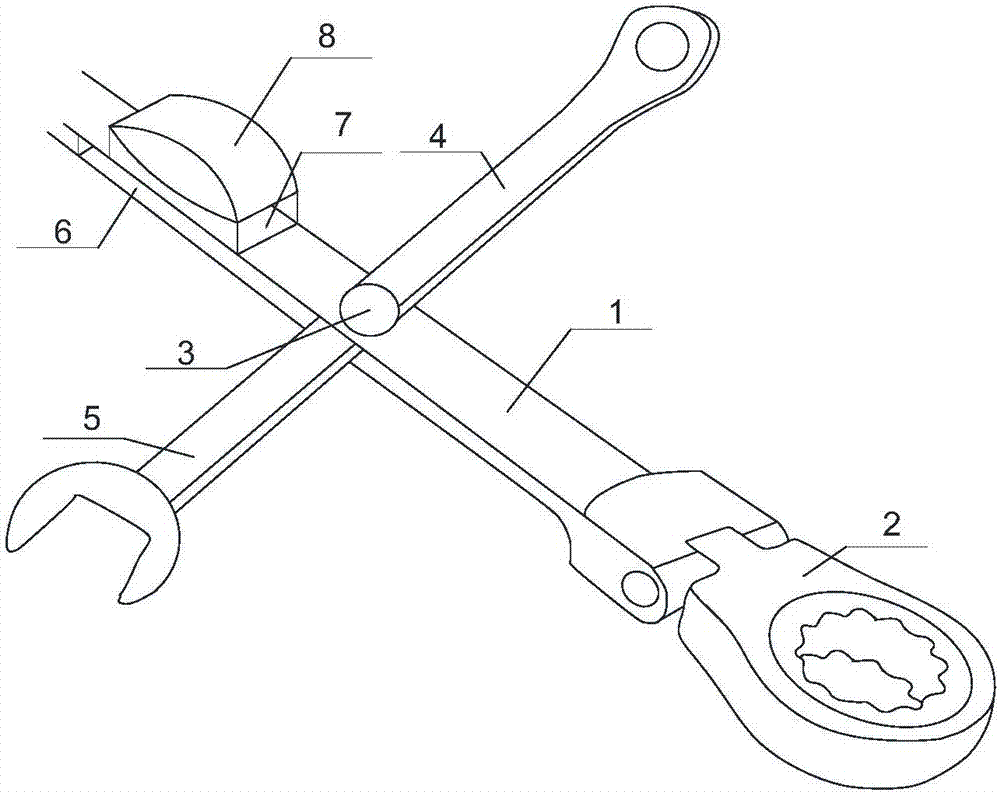

[0022] Such as figure 1 As shown, the wrench head combination type integrated wrench of the present invention includes a handle 1, the front end of the handle 1 is connected with a main wrench head 2, and a through hole is opened on the handle 1, and a rotating shaft 3 is installed in the through hole. The shaft 3 is rotatably connected with a first pair of wrenches 4 and a second pair of wrenches 5. The first pair of wrenches 4 is located above the handle 1, and the second pair of wrenches 5 is located in the middle of the handle 1. There is a second pair of wrenches placed in the handle 1. The groove 6 of the wrench 5, the groove 6 is located on the side of the second secondary wrench 5 away from the main wrench head 2, the upper surface of the handle 1 is provided with a box body 7 for placing the wrench head of the first secondary wrench 4, the The box body 7 is located on the side of the first secondary wrench 4 away from the main wrench head 2 .

[0023] The main suppor...

Embodiment 2

[0025] Based on Embodiment 1, the wrench head of the first pair of wrench 4 is a ring wrench head, and the handle of the first pair of wrench 4 is a telescopic rod. The second secondary wrench 5 is a flat wrench, and the minimum thickness of the second secondary wrench 5 is smaller than the groove depth of the groove 6 . The ring wrench is a wrench commonly used at present, and one of the most used wrenches. Therefore, in the present invention, the first set of wrenches is provided with a ring wrench, or any other wrench, which is convenient for the staff to use. The telescopic rod is used to adjust the first pair of wrenches. The length of the auxiliary wrench is convenient for carrying. The dead end wrench is one of the commonly used wrenches. In the present invention, the second pair of wrenches is set as a dumb head wrench, which is convenient to use. Of course, the second pair of wrenches is not limited to the dumb head pair of wrenches. The thickness of the second pair o...

Embodiment 3

[0027] Based on the above-mentioned embodiment, the top surface of the box body 7 is a concave curved surface, and the top of the box body 7 is connected with a strap 8, the long side of the strap 8 is parallel to the long side of the handle 1, and the box body 7 The top surface is covered with soft pads.

[0028] The concave surface of the box body is held by the staff. During the use of the manual wrench, it is easy to slide and take off the hand, and the wrench is easy to hurt the staff. Therefore, the present invention utilizes the box body and sets the box body as an anti-skid device. Increase the friction between the hand and the box body, and the strap can adjust its tightness according to the size of the bag; therefore, the synergy between the concave surface of the box body, the soft pad and the strap has an anti-slip effect.

[0029] Example 3

[0030] Based on the above-mentioned embodiment, the main board at hand 2 is connected with the handle 1 through a hinge, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com