Milling cutter clamping equipment for manufacturing precision machinery

A technology of precision machinery and clamping equipment, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of inconvenient installation, inconspicuous effect of pressing screw, and inconspicuous installation stability of milling cutters. , to achieve the effect of simple disassembly steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

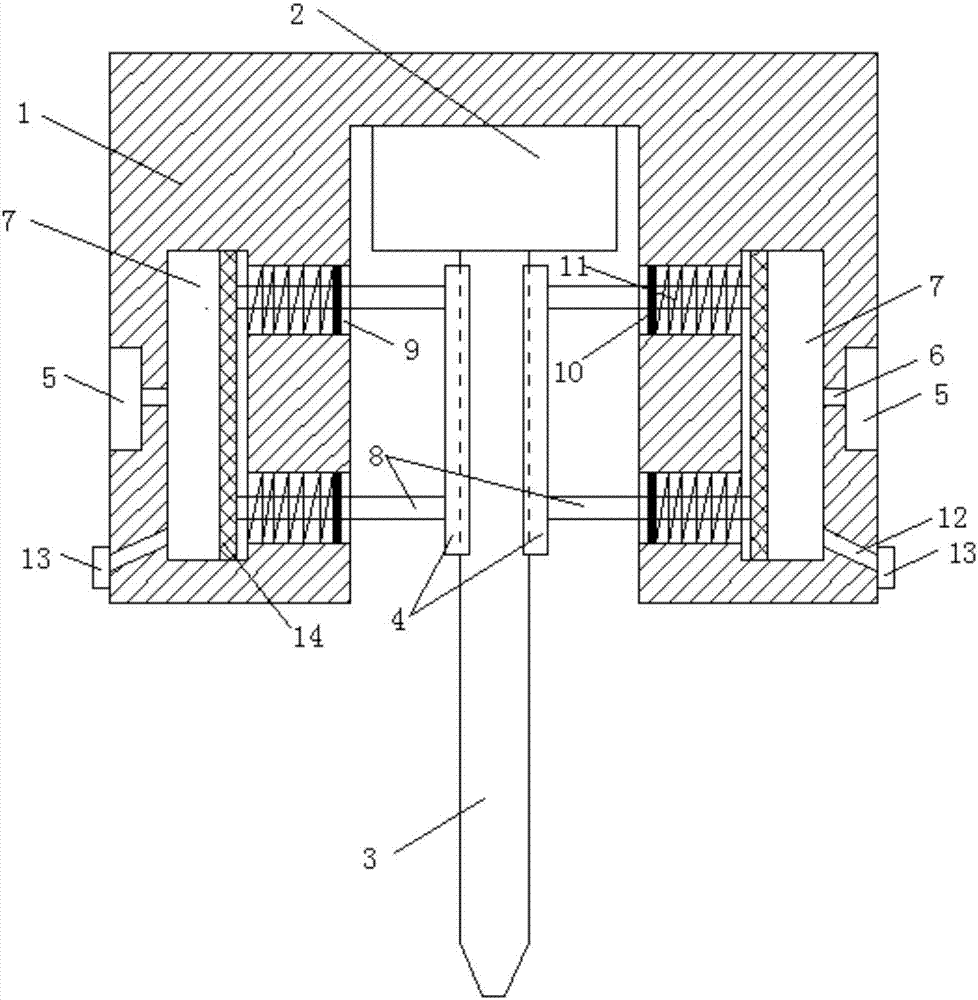

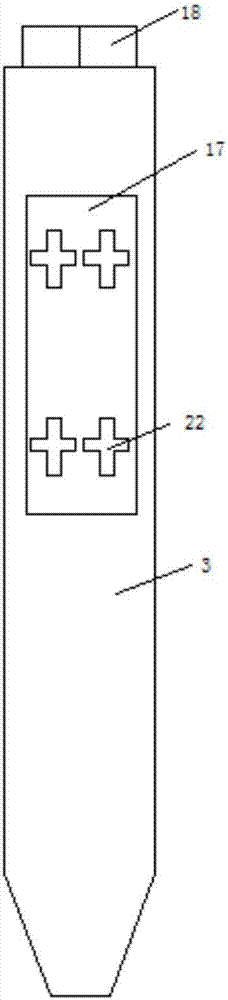

[0032] refer to Figure 1-5 In this embodiment, a milling cutter clamping device for precision machinery manufacturing is proposed, which includes a clamping seat 1 and a milling cutter 3. The clamping seat 1 is a rectangular structure, and a clamp is provided at the center of the bottom of the clamping seat 1. The holding groove, the holding groove is a cylindrical structure, and the central position of the top inner wall of the holding groove is welded with the mounting seat 2, and the central position of the bottom of the mounting seat 2 is provided with a rectangular placement groove 21, and the top of the rectangular placement groove 21 The central position of the inner wall is provided with a five-sided card slot 19, and the interior of the five-sided card slot 19 is fitted with a five-sided card post 18, and the bottom of the five-sided card post 18 is welded with a milling cutter 3, and the top of the milling cutter 3 In contact with the top inner wall of the rectangul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com