Stainless steel overload rotary drum

A technology of stainless steel and drum, applied in small raw hide/big raw hide/leather/fur treatment, leather/skin/leather/hides chemical treatment equipment, small raw hide/big raw hide/leather skin/fur chemical treatment, etc., can solve the problem The chemical materials cannot be recycled, and the chemical materials and leather materials have poor reaction effects, etc., so as to achieve the effects of convenient addition, recycling, and good reaction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

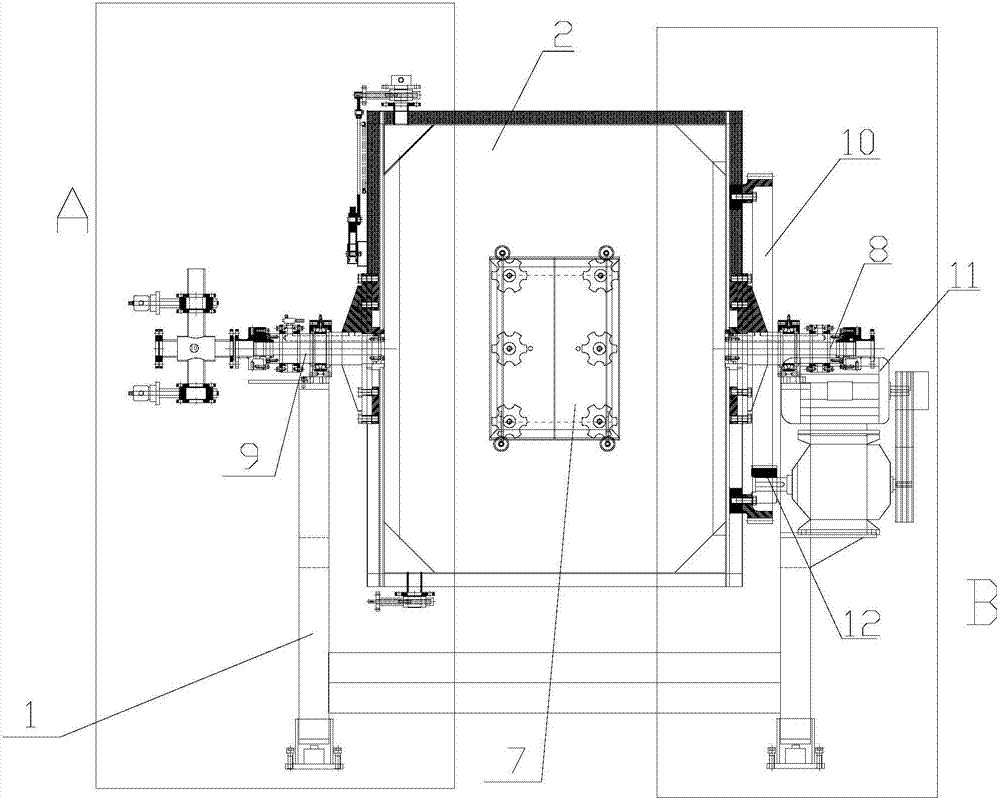

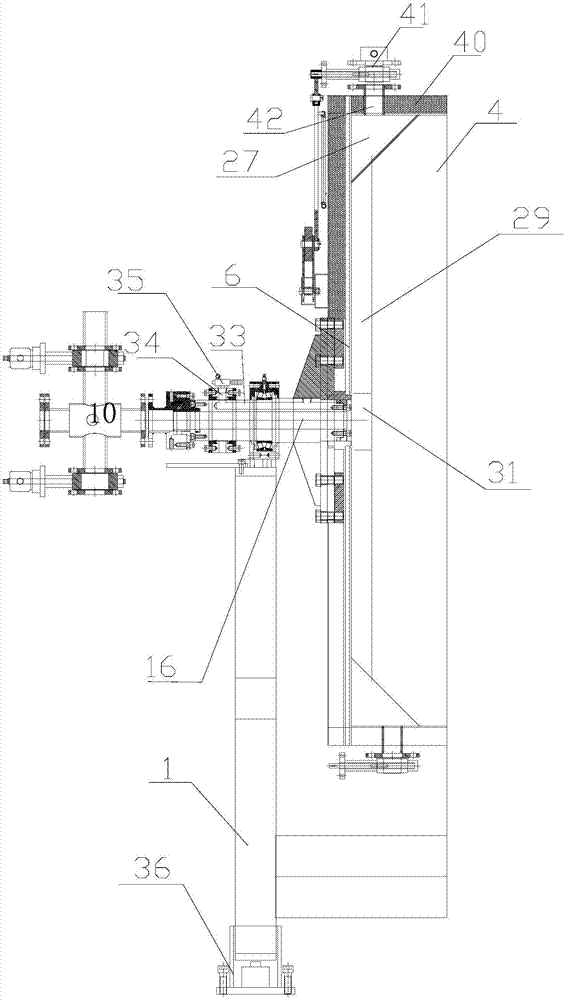

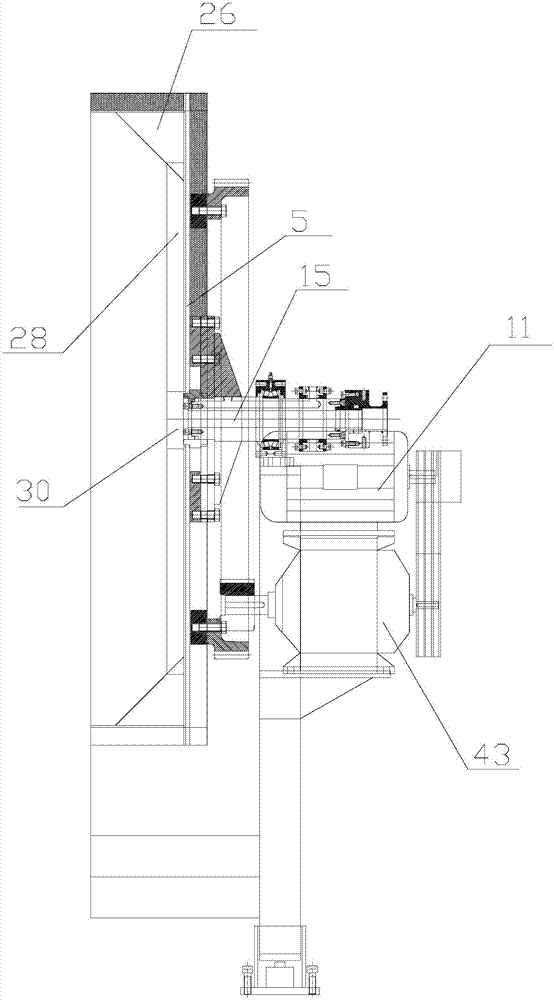

[0030] like Figure 1 to Figure 7 The shown stainless steel overloaded drum includes a bracket 1 , a drum body 2 , a feeding barrel 3 , a circulation system and a driving device that drives the drum body 2 to rotate on the bracket 1 .

[0031]The drum body 2 includes a cylindrical drum shell 4, the two ends of the drum shell 4 are respectively provided with a front drum cover 5 and a rear drum cover 6, and the drum shell 4 is provided with a drum door 7 for adding leather, so the The front drum cover 5 and the rear drum cover 6 are respectively arranged on the support 1 through the front rotating shaft 8 and the rear rotating shaft 9, and the specific structure is that the front end and the rear end of the support 1 are respectively provided with a front bearing seat and a rear bearing seat, and the front bearing seat. The front bearing is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com