Ascidian cellulose nanocrystal/polymer hydrogel and its preparation method and application

A technology of nanocrystals and cellulose, which is applied in the fields of chemical engineering and polymer materials, can solve the problems of poor mechanical properties of hydrogels and hinder practical applications, and achieve the effects of improved tensile strength, good application prospects, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

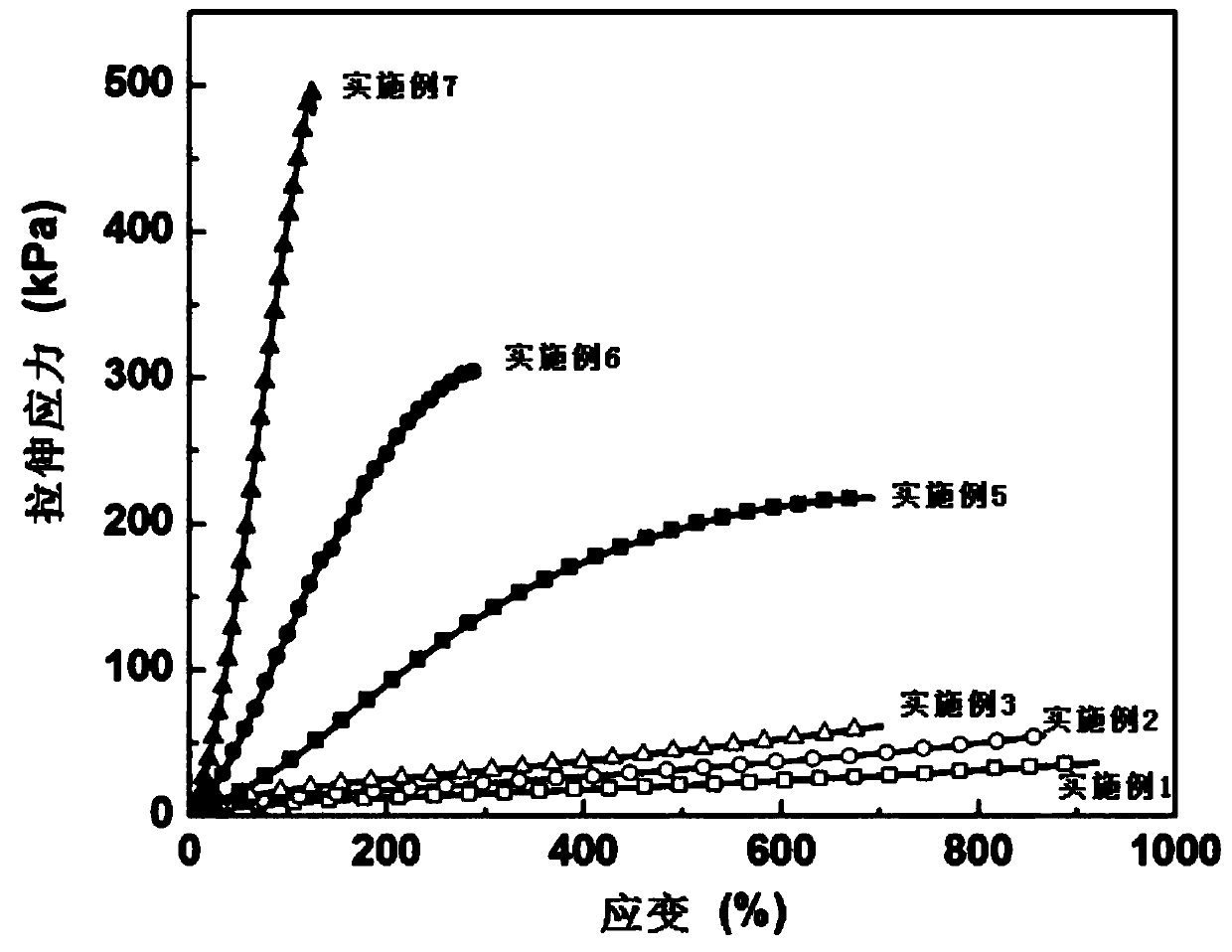

Embodiment 1

[0023] Add 1 g of acrylamide to a small amount of water to dissolve completely, add 0.02 g of potassium persulfate and distilled water to a total weight of 5 g, mix evenly and pour into a mold, and polymerize at 60°C for 3 hours. The obtained sample was washed with water to remove unreacted monomers or initiators to obtain the final polyacrylamide hydrogel. The water content is controlled at 80%, and its tensile strength is measured to be 36kPa.

Embodiment 2

[0025] Add 1 g of acrylamide to a small amount of water to dissolve completely, add 0.05 g of potassium persulfate and distilled water to a total weight of 5 g, mix evenly and pour into a mold, and polymerize at 60°C for 3 hours. The obtained sample was washed with water to remove unreacted monomers or initiators to obtain the final polyacrylamide hydrogel. The water content is controlled at 80%, and its tensile strength is measured to be 54kPa.

Embodiment 3

[0027] Add 1 g of acrylamide to a small amount of water to dissolve completely, add 0.2 g of potassium persulfate and distilled water to a total weight of 5 g, mix evenly and pour into a mold, and polymerize at 60°C for 3 hours. The obtained sample was washed with water to remove unreacted monomers or initiators to obtain the final polyacrylamide hydrogel. The water content is controlled at 80%, and the measured tensile strength is 60kPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com