Folding seat bicycle and manufacturing process thereof

A technology for folding bicycles and folding mechanisms, applied in foldable bicycles, bicycles, motor vehicles, etc., can solve the problems of inconvenience to carry, slow folding speed, and single function, and achieve the effects of easy portability, fast folding speed, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with accompanying drawing:

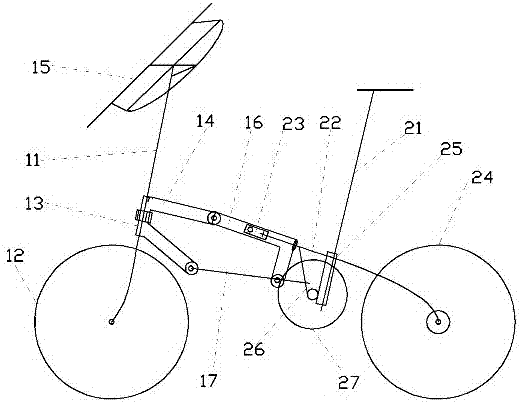

[0048] see figure 1 Shown is a schematic diagram of the vehicle components. It includes a front frame assembly 1 and a rear frame assembly 2. The front vehicle frame assembly 1 is made up of front fork tube 11 and front wheel 12, fixed bowl tube 13, pull tube 14, handlebar 15, pivot joint tube 16, lower link 17 socket or pivot connection. Rear vehicle frame assembly 2 is made up of seat post 21, rear fork tube 22, pipe cap 23, rear wheel 24, seat tube 25, positioning plate 26, chainring shaft 27. The front and rear vehicle frames are pivotally connected with the pipe cap 23 through the pivot pipe 16 .

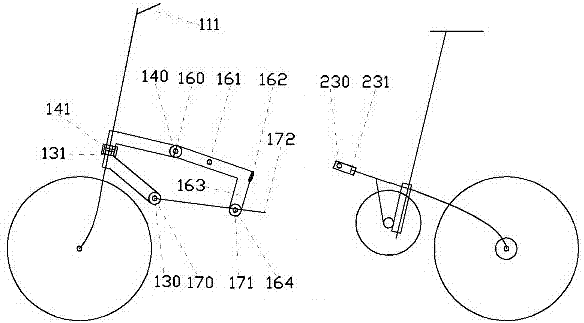

[0049] see figure 2 Shown is a schematic diagram of component alignment. The upper six ports 131 and the lower six ports 141 are hexagonally socketed to make the mechanism more stable. The shaft holes 130 / 170, 140 / 160, and 164 / 171 are pivotally connected, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com