Injection mold with deep-thread bottle cap

An injection mold and deep thread technology, which is applied in the field of injection molds for deep thread bottle caps, can solve the problem that the bottle cap is difficult to come out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

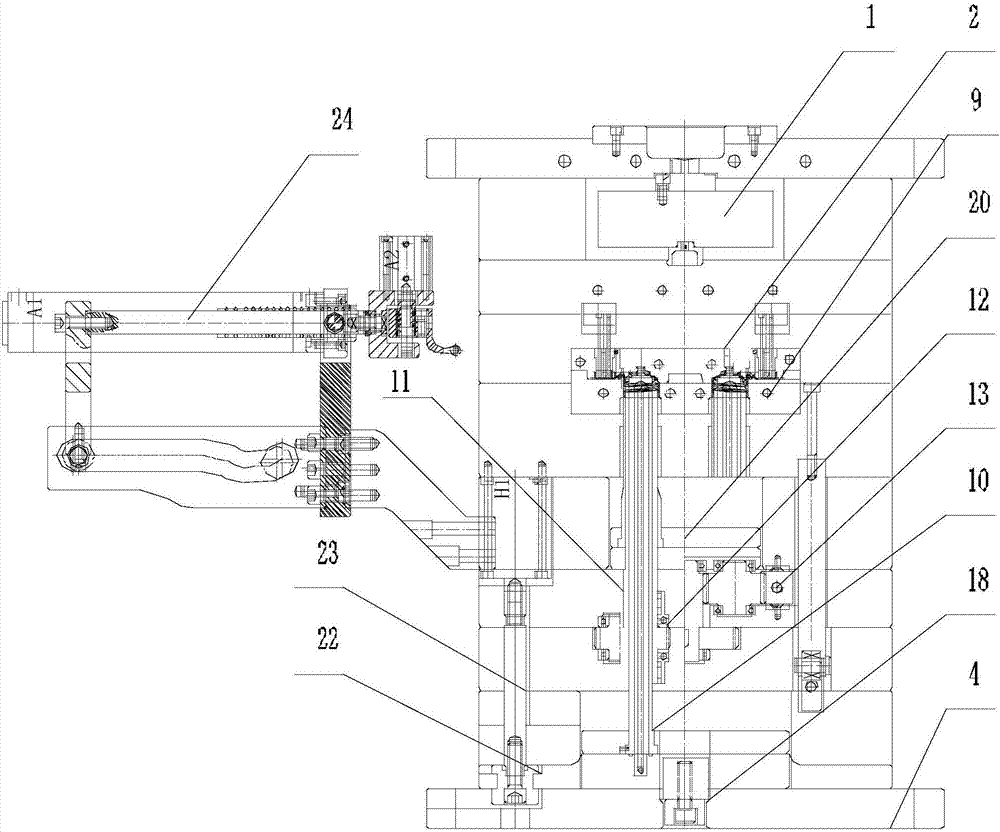

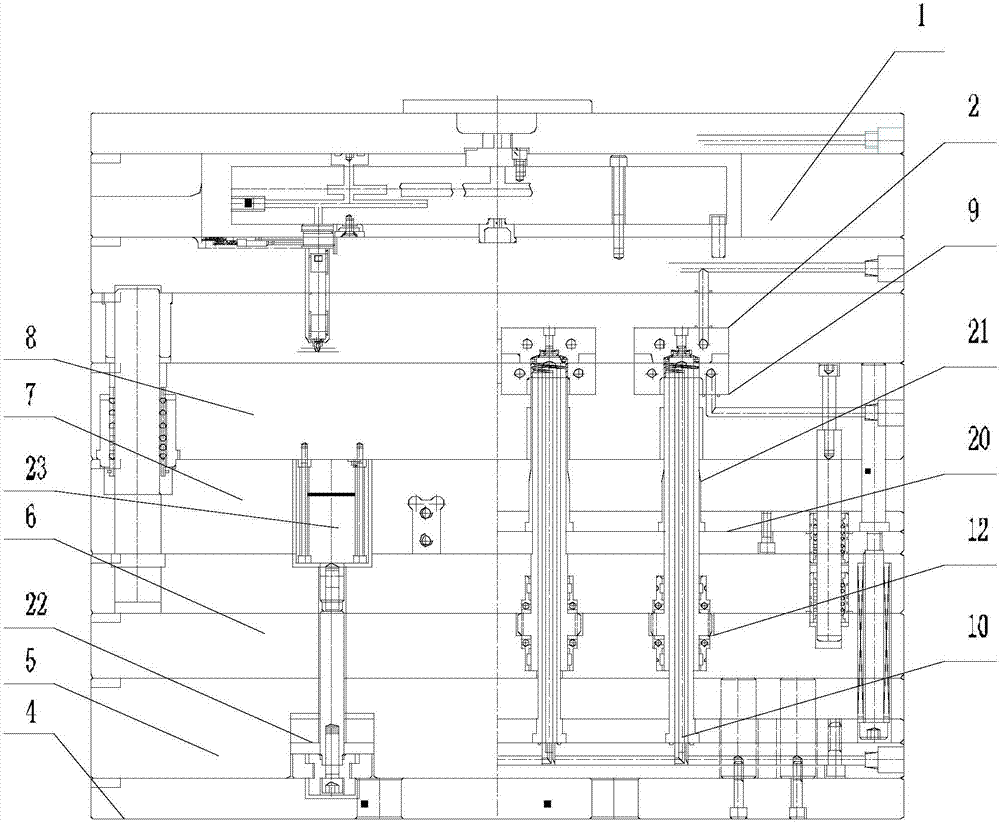

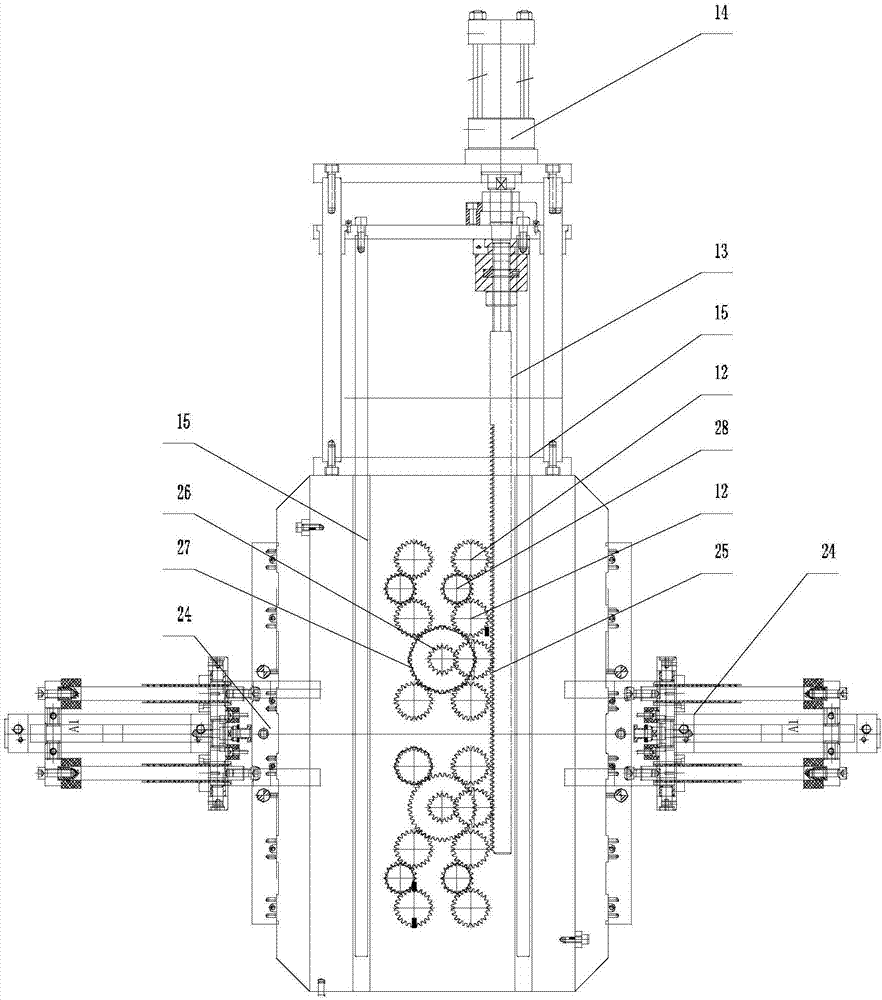

[0024] Such as Figure 1-4 Shown, a kind of injection mold of deep screw bottle cap comprises upper mold 1 and lower mold 3, and upper mold 1 is provided with several upper molding inserts 2, and upper molding insert 2 is provided with upper molding groove, and upper mold 1 Injection channels leading to each upper molding groove are provided in the upper mold 1, and upper cooling channels for cooling each upper molding insert 2 are arranged in the upper mold 1;

[0025] The lower mold 3 includes a lower base 4, and the lower base 4 is sequentially provided with a lower mounting seat 5, a transmission seat 6, an upper mounting seat 7, and a lower forming mold 8, and the lower forming mold 8 corresponds to each upper forming insert 2 A lower mold insert 9 is detachably provided at the bottom of the lower mold insert 9, and a lower molding groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com