Frequency-adjustable vibration screen

A vibrating sieve and sieve plate technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems that the vibration frequency cannot be adjusted according to the needs, the application range is small, and the adjustment cannot be performed, so as to achieve low equipment use and maintenance costs, Easy to increase or decrease, convenience and replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

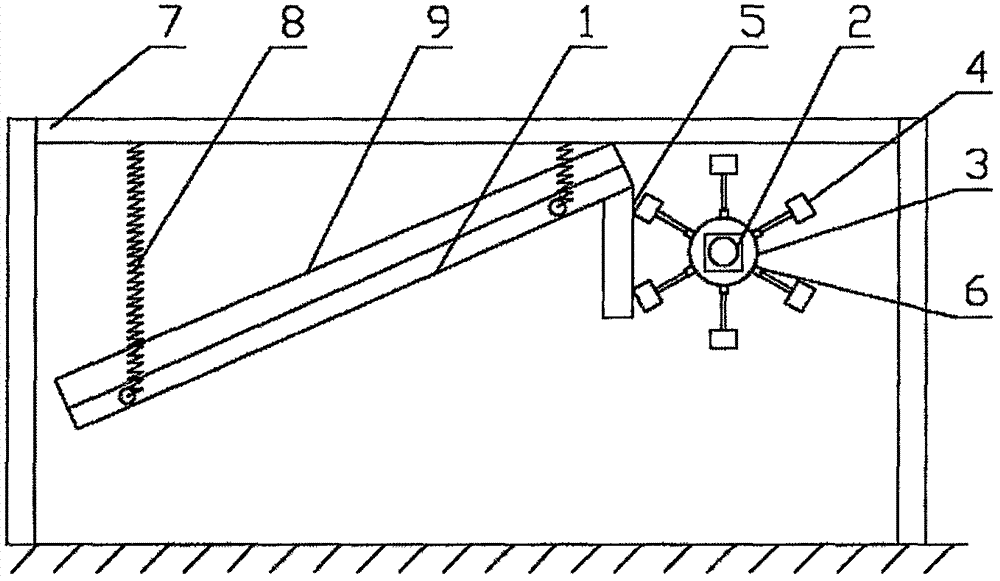

[0023] Such as figure 1 As shown, the frequency-tunable vibrating screen of this embodiment includes a vibrator, a suspension device, and a sieve plate 1 installed on the suspension device, the vibrator includes a drive motor 2, and the drive motor The cylinder installation frame 3 is connected through the reducer, and a group of striking hammers 4 with different phase angles are installed on the cylinder installation frame. When the motor drives the cylinder mounting frame to rotate through the reducer, the impact hammers of different phases continue to strike the force plate of the sieve plate, causing the sieve plate to vibrate. The frequency at which the hammer hits the vibrating screen changes, thereby realizing the function of frequency modulation.

[0024] In the frequency-adjustable vibrating screen described in this embodiment, the sieve plate is connected to the force plate 5, and the force plate is installed on one side of the vibrator. The force plate is set, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com